A 1398 PQA Iron Current Clamp

Current clamp operation

7

3

Current clamp operation

Step 1

Connect A 1398 PQA Iron Current Clamps to the desired input on the measuring instrument.

Step 2

Clamp the probe around the insulated current-carrying conductor(s) to be measured. Make

sure that probe jaws are tightly closed around the conductor(s). In the case of measuring

current near live, naked conductor(s), remove electrical power from wires, before clamping

(follow the requirements of EN 50191).

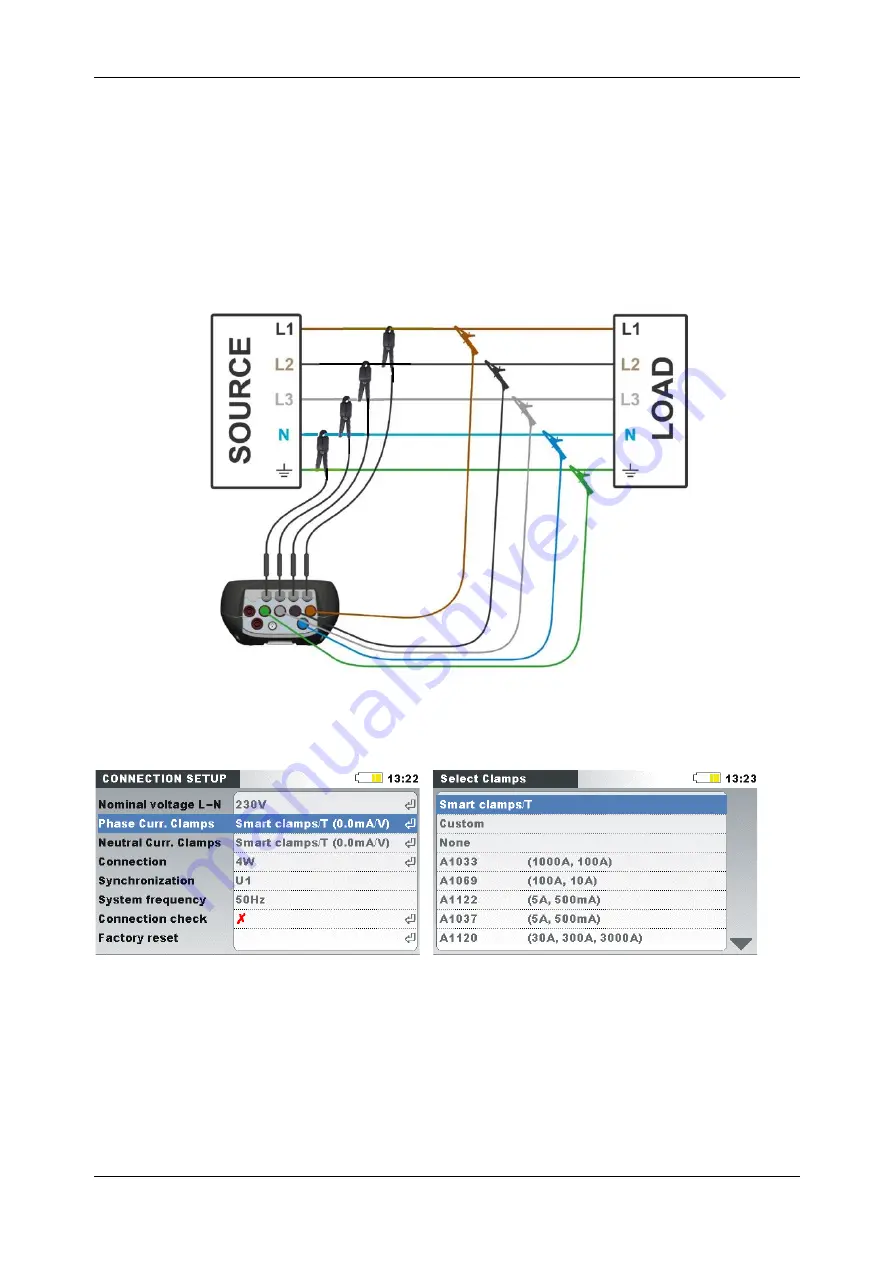

Figure 2: Current clamps A 1398 PQA - connection to the measuring instrument

Step 3

Select Phase and Neutral clamps to

Smart Clamp

in Connection setup menu on your

instrument.

Step 4

Observe the current value and waveform on the instrument’s display.