PAT Appliances & Machines Safety Trainer

AD 3

– MI 3399

223

Measurement on a class II appliance.

Figure 4-14: Example of sub-leakage test on a Class II appliance

AC test signal is applied between connected live pins and accessible conductive parts

not connected to protective circuit. Each accessible part shall be tested alone.

Notes:

On/Off switches must be closed. If after switches were closed all safety relevant

parts are not included the results will be impaired. This is often the case in

electronic or relay driven On/Off circuits. In this case or if in doubt leakage current

tests can be performed as an alternative.

This test cannot be applied on Class II appliances without accessible conductive

parts.

Appliances with leakage currents >3.5mA should be marked.

This measurement returns similar results as leakage tests on powered appliances.

The sub-leakage result is usually higher (up to 2 times) because of connected L

and N conductors.

The sub-leakage test is suitable for IT appliances (at connected mains voltage the

test must last longer to allow booting up the equipment).

4.4.5 Leakage current tests

– general

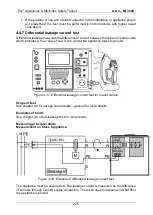

Scope of test

In this test the sum of leakage currents caused by appliance insulation resistances

(resistive currents through the insulation material, fault currents through decreased

insulation) and capacitances (capacitive leakage current) is checked. Even leakage

currents in range of mA are dangerous. The danger increases if the installation is not

properly earthed.

Excessive leakage currents are most often caused by deterioration of the appliance

insulation (pollution, ageing, moisture) or faults in mains circuits of appliances.

In general three leakage currents are measured: the differential leakage current, the PE

conductor (direct) leakage current and the touch leakage current.

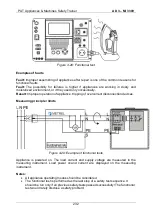

4.4.6 PE conductor leakage current test

This test is sometimes called direct leakage test too.

Summary of Contents for MI 3399

Page 27: ...Electrical Installation Safety Trainer AD 1 MI 3399 27...

Page 46: ...Electrical Installation Safety Trainer AD 1 MI 3399 46 3 Exit settings...

Page 74: ...Electrical Installation Safety Trainer AD 1 MI 3399 74...

Page 197: ...Power and Voltage Quality Trainer AD 2 MI 3399 197 Figure 4 89 Transient Chart view...

Page 204: ...PAT Appliances Machines Safety Trainer AD 3 MI 3399 204...

Page 249: ...PV Photovoltaic Systems Trainer AD 4 MI 3399 249...

Page 250: ...PV Photovoltaic Systems Trainer AD 4 MI 3399 250 AD 4 MI 3399 PV Photovoltaic Systems Trainer...