PAT Appliances & Machines Safety Trainer

AD 3

– MI 3399

224

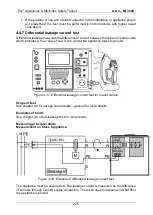

Scope of test

See chapter 4.4.5 Leakage current tests

– general for more details.

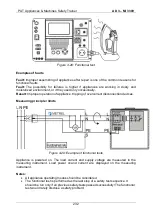

Examples of faults

See chapter 4.4.4 Sub-leakage test for more details.

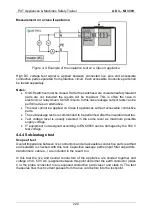

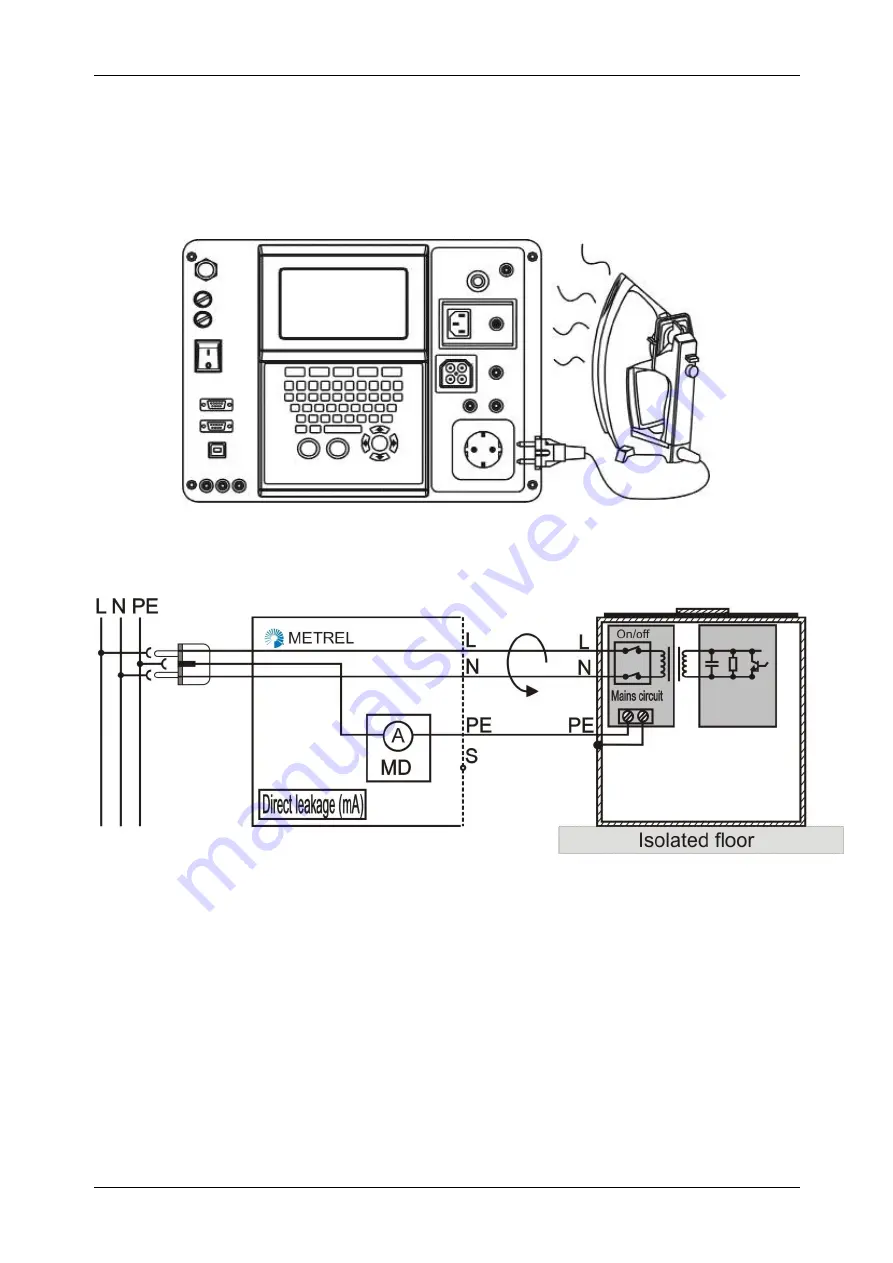

Figure 4-15: PE conductor leakage current test for Class I device

Measuring principle / limits

Measurement on Class I appliance:

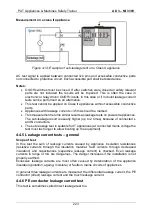

Figure 4-16: Example of the PE conductor current test

The appliance must be powered on. The current flowing through the appliance PE

conductor is measured.

The appliance must be placed isolated against ground to prevent that a part of the

leakage current would flow directly to ground instead through the PE conductor and

ground. This is the main defectiveness compared to the differential leakage test.

Unearthed accessible conductive parts are not included in this test. They are considered

as class II parts and are checked in the Touch Leakage test.

Notes:

If leakage currents differ for different appliance operating modes all modes must

be checked. The highest result (it is the worst) must be considered!

Summary of Contents for MI 3399

Page 27: ...Electrical Installation Safety Trainer AD 1 MI 3399 27...

Page 46: ...Electrical Installation Safety Trainer AD 1 MI 3399 46 3 Exit settings...

Page 74: ...Electrical Installation Safety Trainer AD 1 MI 3399 74...

Page 197: ...Power and Voltage Quality Trainer AD 2 MI 3399 197 Figure 4 89 Transient Chart view...

Page 204: ...PAT Appliances Machines Safety Trainer AD 3 MI 3399 204...

Page 249: ...PV Photovoltaic Systems Trainer AD 4 MI 3399 249...

Page 250: ...PV Photovoltaic Systems Trainer AD 4 MI 3399 250 AD 4 MI 3399 PV Photovoltaic Systems Trainer...