IMO 3/20

IMO-502 EN

7

3. Observe damage of teflon strip(11), if necessary replace it.

4. Clean it with liquid soap solution. After drying apply

grease on rubber parts. Replace these rubber parts.

7.3

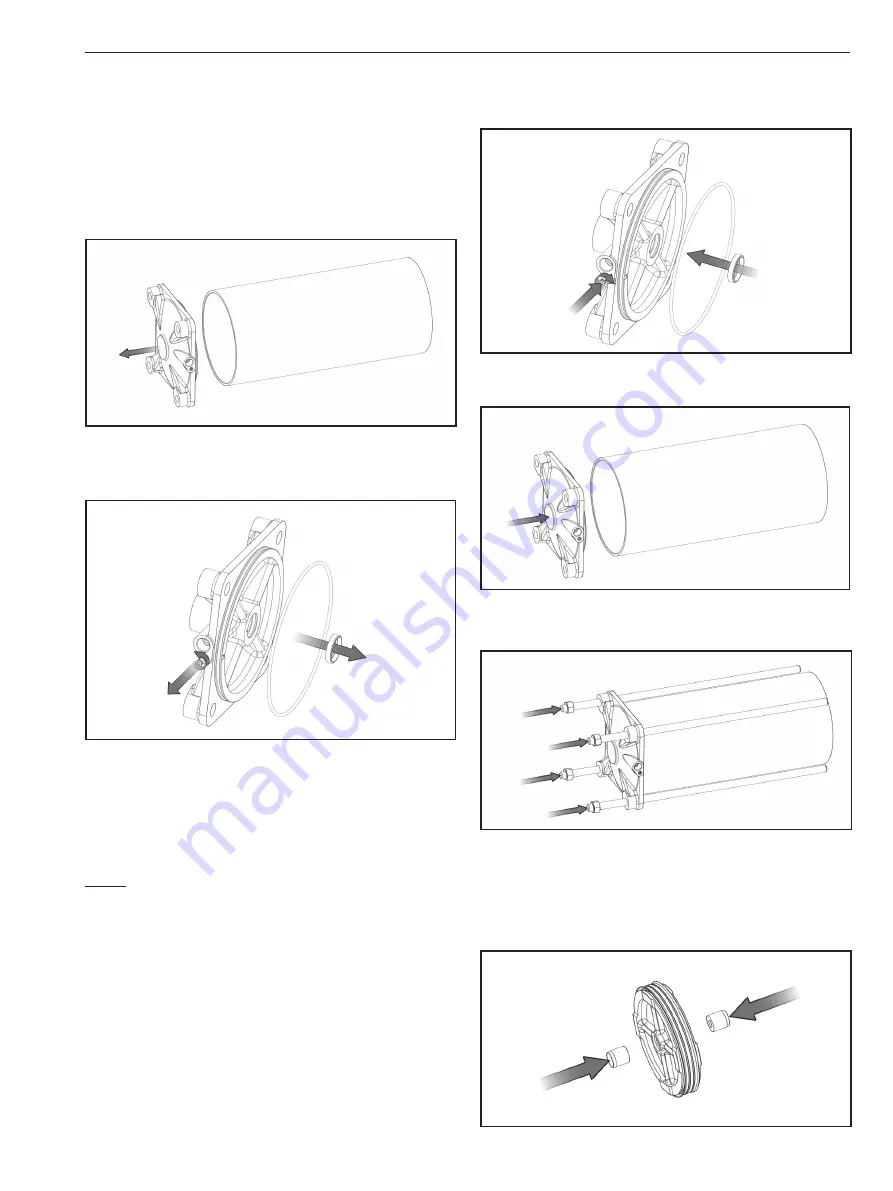

Rear cover disassembly

1. Take out rear cover (2) from tube (3).

2. Remove o-ring (17) and cushion seal (15), take out

cushioning screw (12) with o-ring (19) from the rear

cover (2).

3. Clean tube (3) and rear cover (2) with liquid soap

solution. After drying apply grease on rubber parts and

inside the tube. Replace these rubber parts.

8.

ASSEMBLY

NOTE: When assembling springs and end covers on

cylinder, it is necessary to have the cylinder body in the

vertical position. This is required to ensure that springs

remain properly aligned and centred during assembly. For

single acting cylinder follow the sequences as given below

to ensure proper assembly. For double acting cylinder just

ignore the 5th step in heading 8.2. Piston assembly follow

the sequence to ensure proper assembly.

8.1

Rear cover assembly

1. Clean it with liquid soap solution. After drying apply

RMEBS grease on rubber parts.

2. Place Cushioning seal (15) and o-ring (17) on its groove.

Place o-ring (19) on cushioning screw (12), assemble

the cushioning screw on rear cover.

3. Place the rear cover (2) on tube (3).

4. Assembled the cylinder cover nut (9) and tie rod (6) on

rear cover (3) with tube (3).

8.2

Piston assembly

1. Clean the piston. Apply RMEBS grease on rubber parts.

2. Place lip seal (16) and buffer cap (10) on its groove.

Summary of Contents for JAMESBURY CC Series

Page 11: ...IMO 3 20 IMO 502 EN 11 ...