SECTION 2 - GENERAL INSTALLATION INFORMATION

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

2-27

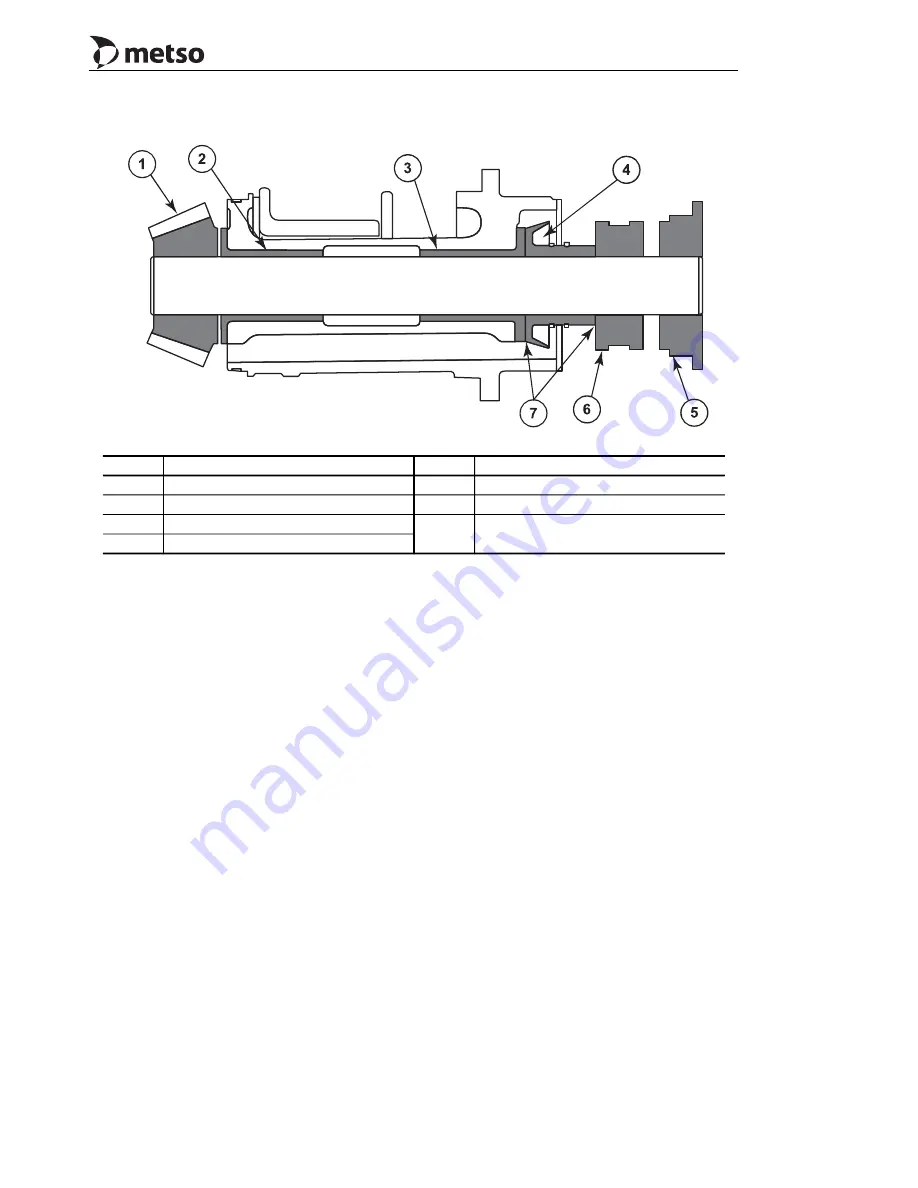

Figure 2-15 End Float - Direct Drive

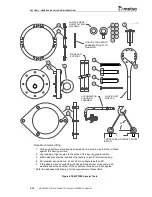

Initial Alignment Of Flexible Coupling

For the initial installation or when reassembling the

flexible coupling on a direct arrangement, it is

always desirable to align the couplings as

accurately as possible for the longest coupling life

and minimum vibration. After the coupling halves

have been properly installed on the shafts, bring the

two halves together and proceed to align the

coupling as follows:

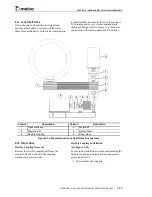

1. Check the gap and angular alignment by

measuring the distance between the coupling

halves, at four places, 90° apart, around the

circumference of the coupling as shown on

Figure 2-16. To measure the gap, use a

feeler gauge or inside calipers or a dial

indicator with a magnetic base. Coupling

halves must be aligned so that all four

measured dimensions DO NOT vary more

than 0.38 mm (0.015").

If any of the four measured dimensions

varies more than the 0.38 mm (0.015"), it

would indicate excessive angular

misalignment.

2. Check parallel alignment by laying a

straight edge across the outside diameter of

the coupling halves, at four places, 90°

apart, around the circumference of the

coupling. See Figure 2-16. Align so that the

straight edge rests squarely on both coupling

halves. Check with a feeler gauge or with a

dial indicator. Parallel misalignment should

NOT exceed 0.38 mm (0.015").

3. Gap, angular and parallel alignment are

important whenever using a flexible

coupling to drive a Crusher.

4. A safety set collar must be installed on the

crusher countershaft to provide the proper

countershaft end float or running clearance.

Refer to the instructions in

Section 4

for the

proper installation of set collar.

Callout

Description

Callout

Description

1

Pinion

5

Flexible Coupling

2

Inner Countershaft Bushing

6

Safety Set Collar

3

Outer Countershaft Bushing

7

Tight

4

Oil Flinger

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...