SECTION 2 - GENERAL INSTALLATION INFORMATION

2-28

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

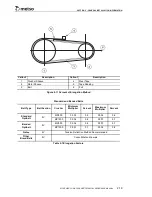

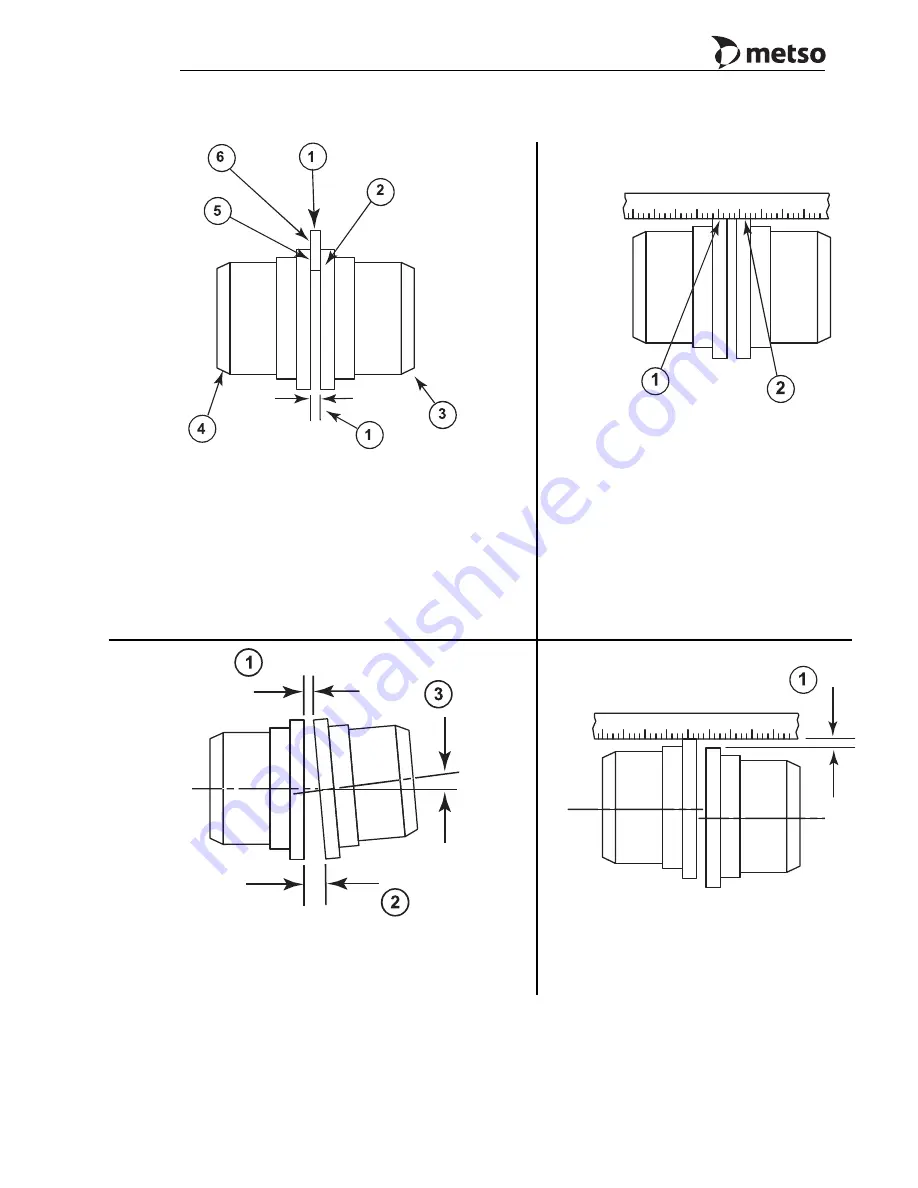

1. Equal Gap

2. Check with Feeler Gauge for Proper Gap and Angular

Alignment on Other Coupling Half at This Point — Check

at 90° Intervals

3. Driving Half of Coupling (Motor)

4. Driven Half of Coupling (Crusher Countershaft)

5. Hold Key Stock Tight against Coupling Half at This Point

6. Use Key Stock for Checking Gap

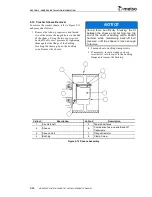

1. Hold Straight Edge Tight Against Coupling

Half at This Point

2. Check with Feeler Gauge for Proper Parallel

Alignment on Other Coupling Half at This

Point — Check at 90°Intervals

1. 0.38 mm (0.015

"

) Maximum Parallel Misalignment

Figure 2-16 Coupling alignment

CORRECT GAP AND ANGULAR ALIGNMENT

CORRECT PARALLEL ALIGNMENT

1. Gap

2. 0.38 mm (0.015

"

) Maximum Gap and Angular Misalignment

3. Angular Misalignment

INCORRECT GAP AND ANGULAR ALIGNMENT

INCORRECT PARALLEL ALIGNMENT

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...