SECTION 2 - GENERAL INSTALLATION INFORMATION

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

2-37

2.20 Protecting the Crusher Against Rust

Corrosion

To protect your Crusher from rust corrosion during

seasonal shutdown or for outdoor storage (winter or

summer), the following protective measures are

recommended:

1. Remove the bowl, feed plate, head, socket

and eccentric assemblies. Disconnect the oil

drain line at the bottom of the main frame

and the oil pressure inlet at the bottom of the

main shaft. Make sure that all piping and the

hole in the bottom of the main shaft are

sealed with blind flanges and gaskets.

2. Use a wide paintbrush to paint all inside

surfaces of the main frame with rust

preventive lubricating oil.

Use lubricating oil which has a rust

preventive blend that is designed for the

protection of internal parts of enclosed

assemblies such as engines, compressors,

pumps, gear sets, and hydraulic assemblies.

Metso Minerals suggests the use of

Mobilarma 522 or equivalent. The rust

preventives function by displacing water

from metal surfaces, by forming strong

water-resistant films on the surfaces, and by

absorbing water in the system into a

water-in-oil emulsion. These products

provide as much as 30 to 40 times the

protection against rust as high quality

lubrication oils that have not been especially

formulated to prevent rust.

In most applications, the residual rust

preventive film left by these products need

not be flushed away or otherwise removed

when the Crusher is to be filled with

lubricating oil and put into normal service.

Generally, 208 liters (55 U.S. gallons) is

sufficient to coat a Crusher. The viscosity of

the oil should be in the 150 to 300 SSU at

38°C (100°F) range.

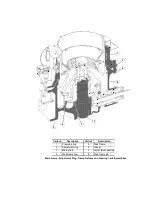

3. Using the paintbrush, coat the lower thrust

bearing, the outer surface of the main shaft,

and all exposed surfaces of the pinion with

rust preventive oil. Remove the countershaft

box oil feed hose from the side of the

countershaft box. Place a funnel in the hole

at the countershaft box and pour oil into the

countershaft box while rotating the

countershaft. Approximately 20 liters

(5 U.S. gallons) will be required to coat the

entire countershaft box area. Some leaking

will occur from the drive end of the

countershaft box, this is normal.

Reinstall the oil feed hose to the

countershaft box.

4. Fill the lubricating hole in the main shaft

with Mobilarma 522 or equivalent until the

hole is filled with oil, then drain.

5. Coat the outer surface of the eccentric, the

bore of the eccentric bushing, the gear and

the upper thrust bearing with Mobilarma 522

or equivalent.

6. Brush a coating of the special oil onto the

head ball, the bore of the upper and lower

head bushings, machined surfaces of the

head above the head ball (if the Crusher uses

a clutch style antispin device some

additional disassembly may be required) and

all areas of the head adjacent to the T-seal.

7. Reinstall the eccentric assembly and the

socket assembly. Apply a coat of the special

oil to the bearing surface of the socket liner

and the exposed surfaces of the socket.

Install the head assembly and then the feed

plate.

8. Fill the oil tank on the power unit with

similar rust preventive oil having a viscosity

of 150 SSU at 38°C (100°F). 380 liters

(100 U.S. gallons) are required for the entire

hydraulic system. Make sure the oil is

compatible with the oil specified for

operation of the Crusher as well as a

hydraulic system where neoprene,

polyurethane, bronze, nickel, chrome, steel

and iron are used.

The hydraulic tramp release, clamping, bowl

clearing and bowl turning mechanisms must

be operated to assure that the power unit and

NOTICE

If the recommendations listed below are

followed, a Crusher stored outdoors should

have 6 - 12 months of rust protection.

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...