SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

3-7

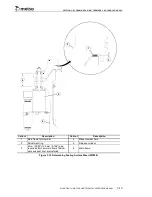

3.3.5 Main Frame Pins and Pin Bushings

The main frame pins prevent the adjustment ring

from rotating in respect to the main frame and also

guide the adjustment ring back to its original

position when the ring lifts due to tramp iron or

packed material in the crushing cavity (refer to

Figure 3-6). Repeated adjustment ring lift is not

normal, is not an acceptable method of operation,

and can usually be corrected by proper feeding and

correct crusher settings.

Incorrect operation with excessive ring movement

will result in wear of main frame pins and worn pin

bushings. See below for proper procedure for

checking for bushing wear. Any wear on the main

frame pin bushing is easily checked once the pin

covers are removed. Due to the rotation of the head

in relationship to the bowl, the adjustment ring will

want to rotate in the opposite direction as the head

rotation. Since this force will be acting on the

adjustment ring in one direction only, the main

frame pins and the pin bushing in the adjustment

ring will have a tendency to wear on one side only.

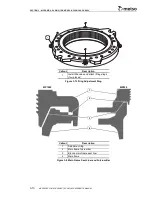

Excessive pin or bushing wear will result in a

concentration of wear on the release cylinder rods

in the area where the rods pass through the main

frame. The main frame pins and the pin bushings

should be replaced when they show signs of

excessive wear. Since excessive pin wear is

unusual, the main frame pins will rarely require

replacement.

Replace pin bushing as follows:

1. Lock out and tag all electrical power

supplied to the power unit and Crusher and

depressurize the clamping and tramp release

circuits by opening the clamping cylinder

and tramp release cylinder needle valves

located on the side of the hydraulic power

unit at the hose connection area.

2. Remove the pin covers to inspect the pin

bushings for wear. If the pin bushings show

excessive wear continue with the

replacement procedure.

3. Slightly lift the adjustment ring off the

frame and rotate the ring to center the main

frame pins in the bushings. Refer to

Figure 3-7 for correct lifting of adjustment

ring.

4. Once the pin is centered, remove the

bushing by prying the bushings out.

NOTICE

Allowing the adjustment ring to bounce will

void the warranty.

WARNING

Prior to performing maintenance work on

any part of the Crusher, lockout and tag all

electrical power supplied to the power unit

and Crusher and release stored pressure in

all hydraulic circuits. Death or serious injury

may result if the Crusher systems are

activated while personnel are in, on or near

the Crusher. Turn the POWER OFF/ON

switch located on the local control station to

the OFF position and lock out and tag the

power supply to the power unit and Crusher.

Depressurize the hydraulic circuits by

opening (turn counter-clockwise) the needle

valves located at the hydraulic power unit

cabinet. This will vent the pressurized oil in

the circuits back to tank but it will not release

the nitrogen pre-charge pressure in the

clamping circuit accumulator found inside

the power unit or the tramp release circuit

accumulators shared by the tramp release

cylinders. Do not perform maintenance on

any accumulator until the hydraulic circuits

have been depressurized and the nitrogen

pre-charge pressure is safely released.

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...