SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

3-8

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

5. To install a new pin bushing, pack the bore

of the replacement bushings with dry ice for

two to three hours to shrink the bushings for

easy installation into the adjustment ring.

Simply slide the new bushings into the

adjustment ring and install the pin cover.

6. Slightly lift the adjustment ring off the

frame and turn the ring clockwise until the

ring comes in contact with the main frame

pins. With the ring against the pins, lower

the ring onto the frame.

7. Close the clamping and tramp release

cylinder needle valves located on the side of

the power unit, then activate the power unit

and repressurize the clamp and tramp

release circuits.

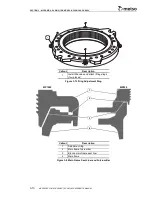

Replace the pins as follows:

1. Lock out and tag all electrical power

supplied to the power unit and Crusher and

depressurize the clamping and tramp release

circuits by opening the clamping cylinder

and tramp release cylinder needle valves

located on the side of the hydraulic power

unit at the hose connection area.

2. Remove capscrew, lockwasher and large

diameter washer from the underside of each

main frame pin to be replaced.

3. Force the worn pin out through the top of the

main frame using a hydraulic jack centered

under the pin. Heating of the frame boss

may be required.

If the pin can not be removed by this method

then cut out the center of the pin with a

lance, then retry step 3.

4. Heat the pin boss on the frame to ease

installation. Drive the new pin in the main

frame by sledging. The pins must be seated

against the bottom of the counterbored hole

in the frame.

5. Fasten the main frame pin to the frame with

large diameter washer, lockwasher and

capscrew.

6. Slightly lift the adjustment ring off the

frame and turn the ring clockwise until the

ring comes in contact with the main frame

pins. With the ring against the pins, lower

the ring onto the frame.

7. Close the release cylinder needle valve on

the side of the power unit, then activate the

power unit and repressurize the tramp

release cylinders.

NOTICE

Wrap the outside of the bushing in a few

layers of fiber glass insulation to prevent the

external build-up of frost which could hinder

the installation of the bushing in the

adjustment ring. This also helps to achieve a

more thorough cooling.

WARNING

Use heavy, well insulated gloves when

handling dry ice. Handling dry ice without

the proper protection could result in severe

burns.

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...