SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

3-12

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

MP800

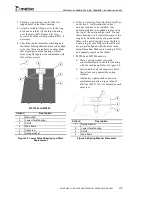

1. Starting at any release cylinder, identify, on

the outside surface of the adjustment ring

flange, four spots 90° apart by stamping or

painting the numbers 1, 2, 3 and 4.

2. Measure the distance from the top of the

adjustment ring flange to the bottom surface

of the upper main frame flange at the four

numbered spots as shown in Figure 3-10.

Record these measurements.

3. At periodic intervals remeasure these points

and compare them to the original

dimensions. Comparing the two sets of

dimensions will show at a glance how much

wear has taken place and if the wear is even

all the way around the Crusher. Due to

casting and machining variations this is the

only accurate method in which wear can be

determined.

4. When any one of the four check dimensions

measures less than the initial recorded

dimensions by the amount shown in

Table 3-1 the seat liner and fulcrum bars

need replacing. This much vertical wear

means that only 5 mm (0.19") of material is

left on the seat liner.

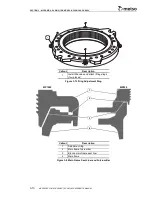

The 8 mm (0.32") difference between the two

measurements indicates the seating surface has

worn and, according to the table, the seat liner and

fulcrum bars need replacing.

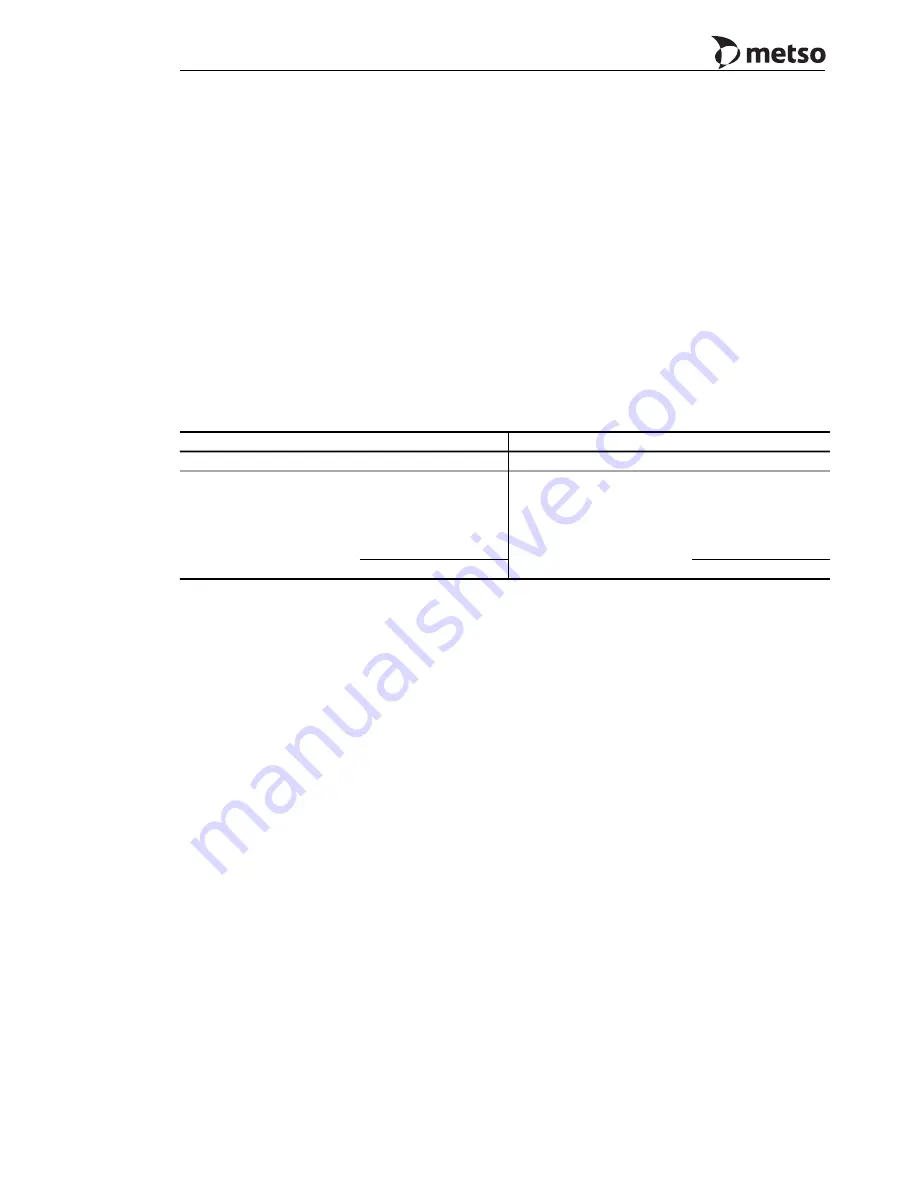

Table 3-1 Seat Liner Wear

MP800

MP1000

Maximum Vertical Wear

8 mm (0.32")

Maximum vertical wear

10 mm (0.38")

Example:

Example:

Original recorded

measurement

350 mm (13.78")

Periodic dimensional check

50 mm (2.00")

Periodic dimensional check 342 mm (13.46")

Original recorded

measurement

40 mm (1.62")

Difference

8 mm (0.32")

Difference

10 mm (0.38")

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...