SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

3-14

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

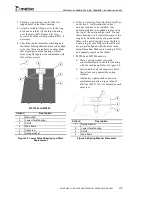

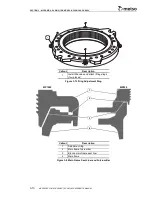

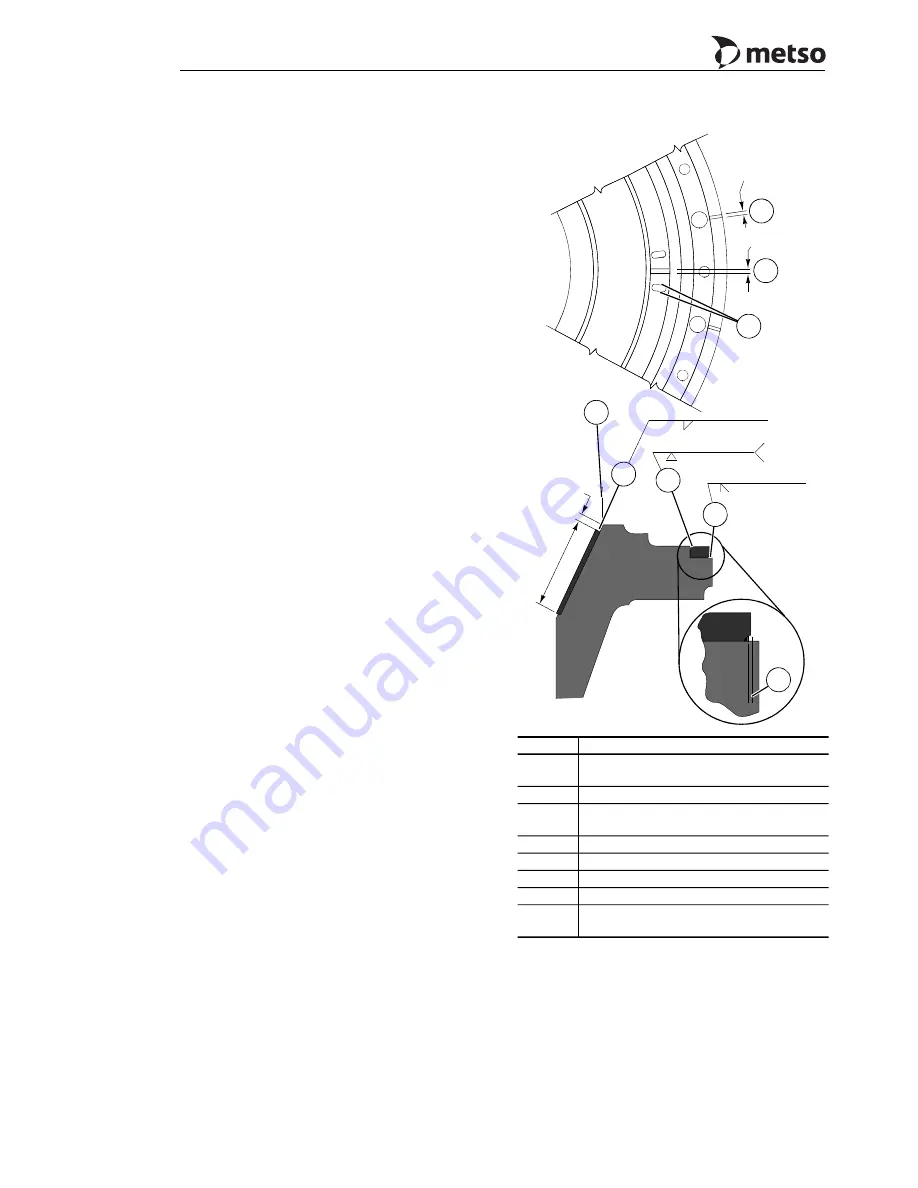

3.4.3 Main Frame Seat and Fulcrum Bar

Installation

There is a gap between the main frame fulcrum bar

and adjustment ring fulcrum surface that is to be

maintained when seat liners and fulcrum bars are

replaced. Refer to Figure 3-9 for the MP1000 or

Figure 3-10 for the MP800.

Over a long period of time, the adjustment ring

conical seating surface will experience wear, even

though it seats on a bronze frame seat liner. If

enough adjustment ring wear occurs, the desired

gap between the frame fulcrum bars and adjustment

ring fulcrum surface will not be obtainable even

though a new seat liner and fulcrum bars have been

installed. It is very important that this gap is

maintained when new seat liners and fulcrum bars

are installed so the adjustment ring seats properly

on the bronze frame seat liner and not on the frame

fulcrum bars and adjustment ring.

If the adjustment ring is allowed to rest on the

fulcrum bars instead of on the frame seat liner,

major adjustment ring failure could occur. The

procedure for seat liner, fulcrum bar replacement

and possible adjustment ring rework is as follows.

MP1000

For the following procedure refer to Figure 3-11.

1. Remove worn bronze main frame seat liner

and fulcrum bar.

2. The replacement main frame seat liner and

fulcrum bar will be shipped in segments.

3. Position the seat liner at the dimension

shown and weld using 4 mm (0.16") weld

rod which meets AWS E Cu AL-A2 or R Cu

AL-A2 specification. Do not butt vertical

joints.

4. When using these 4 mm (0.16") weld rods

reverse polarity and use between 130 to

190 amps. The main frame seat and seat

liner must be preheated to 20°C (68°F) to

40°C (105°F).

5. Weld the fulcrum bar as shown.

6. After welding a new seat liner and fulcrum

bar to the main frame place balls of clay or

putty around the top outside corner of the

main frame flange.

Figure 3-11 MP1000 Main Frame Seat Liner and

Fulcrum Bar

Callout

Description

1

Typical gap between fulcrum bar

segments

2

Typical gap between seat liners

3

9 mm (0.37") typ. braze length. Braze

along sides of slot only — 16 places

4

3280 mm (129.13") diameter

5

Braze along top of segments

6

Weld typ. 16 segments

7

Weld typ. 16 segments

8

5 mm (0.20") weld must be recessed to

this dimension

32

5

m

m

10 mm (.39")

24 mm (.94")

19 mm

9 mm 100 mm-300 mm

50 mm-150 mm

50 mm-150 mm

16

1

2

3

4

5

6

7

8

(.35") (4"-12")

(2"-6")

(2"-6")

(.75")

(1

2.

8"

)R

EF

segments

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...