SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

3-16

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

8. Lift the adjustment ring from the frame and

measure the thickness of the clay or putty

balls.

a. If the clay ball thicknesses are less than

2 mm (0.080") the minimum distance

shown in Figure 3-9 then the adjustment

ring fulcrum surface is to be machined to

obtain the minimum clearance. Refer to

the following example:

b. If the clay ball thicknesses are more than

5 mm (0.196"), the maximum distance

shown in Figure 3-10, then the

adjustment ring fulcrum surface is to be

built up with weld and machined to

obtain at least the maximum clearance. If

weld build up is required, then contact

Metso Minerals for weld and machining

procedures.

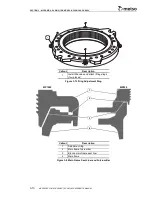

Figure 3-13 MP800 Main Frame Seat Liner and

Fulcrum Bar

Callout

Description

1

4 Segments

2

Braze along sides of slots only —

18 places

3

Typ. gap between seat liner and fulcrum

bar segments

4

6 Segments

3 mm (.12")

10 mm (.39")

20 mm (.79")

75-285 mm (3-11.22")

2

3

1

22 mm

6 mm

Ø 2725 mm

100-260 mm

250 mm

4

(.87")

(.25")

(4-10.24")

(9.84") REF

(107.29")

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

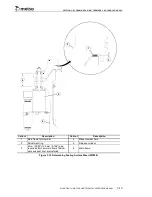

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...