SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

3-20

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

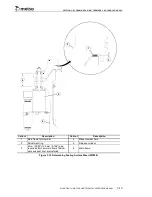

4. Thread an M20 eyebolt into the end of the

cylinder rod. The eyebolt must be turned

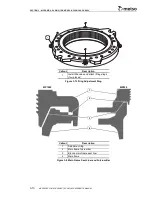

down completely so that the shoulder of the

eyebolt is seated on the top surface of the

cylinder rod. The M20 eyebolt used must

have a diameter not to exceed 72 mm

(2.83") in order to pass through the rod nut.

5. Lower a lifting sling from an overhead crane

through the hole in the drive ring. Thread

the rod nut then the upper bearing cone with

the bevel pointing down onto the sling

before passing the sling through the hole in

the adjustment ring and main frame down to

the floor or platform. For the

MP800

also

locate the rod seal between the flanges of the

adjustment ring and main frame before the

sling is passed through the holes in the

adjustment ring and main frame.

If an overhead crane is not available,

scaffolding can be built to support a chain

hoist to install the tramp release cylinder

assembly.

6. Connect the sling to the eyebolt with a

shackle. The shackle and sling used to

connect to the eyebolt must have adequate

capacity and a width not to exceed 72 mm

(2.83") in order to pass through the rod nut.

7. Carefully raise the tramp release cylinder

rod through the hole in the main frame and

adjustment ring.

8. With the threaded end of the cylinder rod

above the top of the adjustment ring, first

coat the bearing cone with “never seize”

then slide the bearing cone over the top of

the rod until it seats on the flange just below

the threads. Then screw the rod nut onto the

rod end until it bottoms out on the bearing

cone.

9. Lower the tramp release cylinder until the

bearing cone seats in the bearing cup and the

lifting sling slackens. Disconnect the lifting

sling and unscrew the eyebolt from the end

of the cylinder rod. Plug the threaded hole at

the end of the cylinder rod with an M20 bolt

or with grease to protect the threads and

keep the hole from filling up with dirt.

10. Rotate the release cylinder so the manifold

block on the cylinder is pointing outward

from the Crusher.

11. Reconnect the tramp release system hoses to

the release cylinder. Pressurize the

accumulator with nitrogen to the proper

pre-charge pressure. Refer to

Checking

Pre-Charge Pressure and Charging the

Accumulator (Tramp Release System)

in

Section 12

for information on pressurizing

the accumulator to the pre-charge pressure.

12. After the cylinder is installed and all

connections completed, the system must be

bled to remove any entrapped air. The

system is then to be pressurized and checked

for leaks. Refer to

Section 12

for

information on bleeding and checking the

tramp release system.

WARNING

Provide safe work platforms for all

maintenance and operational requirements.

Death or serious injury may result from a fall

from an unstable or inadequate work

platform. Work platforms must be anchored

to provide adequate stability and must be

structurally able to support the loads

sustained

during

any

maintenance

operation. Workers must also be prepared

with fall arrest harness equipment. Follow all

OSHA, MSHA and site specific guidelines

for the requirements of working from

elevated platforms.

NOTICE

Do not pump oil into the tramp release

circuit before the accumulators are

pre-charged with nitrogen. This could

damage the bladder and necessitate an

accumulator replacement.

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...