SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

3-21

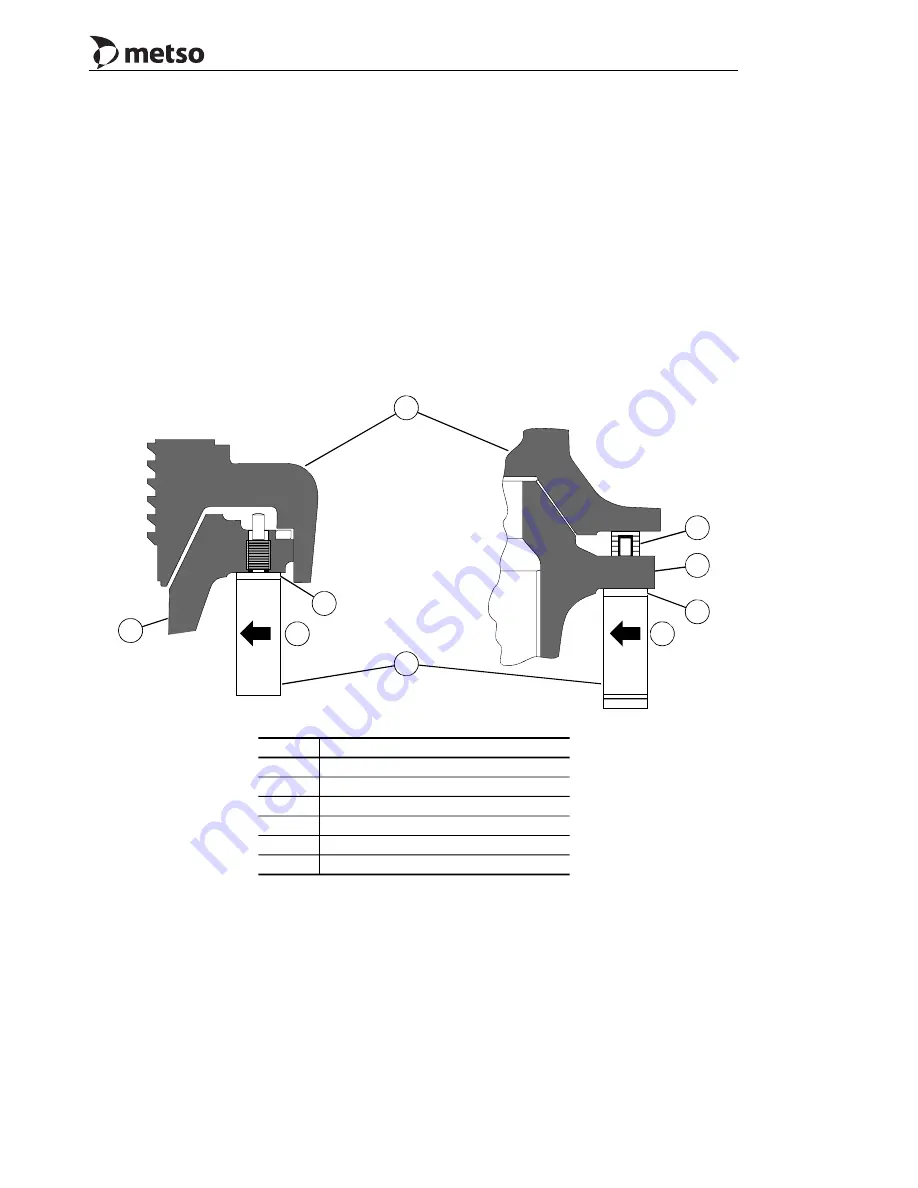

3.4.6 Clearing Jack Removal

A leaking clearing jack is a condition which should

prompt attention. A leaking cylinder will result in

the ring not raising during a clearing operation.

Leaky seals could also cause the ring to creep down

after being raised during a clearing operation. To

remove a leaking cylinder for replacement or repair

proceed as follows (refer to Figure 3-16):

1. Lock out and tag all electrical power

supplied to the power unit and Crusher.

2. Disconnect hose from the cylinder. Plug and

cap open ports to prevent loss of oil and

prevent the entry of dirt.

3. Attach a sling around the cylinder, and

attach the free end of the sling to a suitable

lifting device. Take up the slack in the sling.

4. Attach a pipe strap wrench around the

cylinder head of the clearing jack and turn

the jack in a counterclockwise direction as

seen from below the cylinder and as shown

in Figure 3-16.

5. After the jack is free of the main frame

flange slowly lower the cylinder until the

cylinder push rod clears the underside of the

main frame flange.

6. Refer to

Section 12

for clearing jack

cylinder rebuilding instructions.

Figure 3-16 Clearing Jack Cylinder

Callout

Description

1

Adjustment ring

2

Main frame

3

Unscrew

4

Clearing jack cylinder

5

Rod seal

6

Tack weld

1

4

3

3

6

2

6

2

5

MP1000

MP800

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...