SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

3-28

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

3.4.12 Adjustment Ring Disassembly

The various sealing and clamping components that

are associated with the adjustment ring can be

detached and removed from the adjustment ring

while the adjustment ring is left in place on the

main frame. Main frame seat liner or fulcrum bar

replacement will, however, require that the

adjustment ring be removed from the main frame.

To detach and remove the adjustment ring

components, proceed as follows:

1. Remove the bowl assembly as instructed in

Section 8

.

2. If the clamping ring is to be removed from

the adjustment ring, then first remove the

dust shell from the adjustment ring by

removing the series of capscrews and

lockwashers installed around its lower

flange and then lift the shell off the ring.

If the clamping ring is not to be removed

from the adjustment ring, then proceed to

step 6.

3. Remove the hex head bolts and spacers that

are used to hold the clamp ring when the

bowl assembly is rotated. There are eight

bolts and spacers on the MP1000 and six on

the MP800. Refer to Figure 3-23.

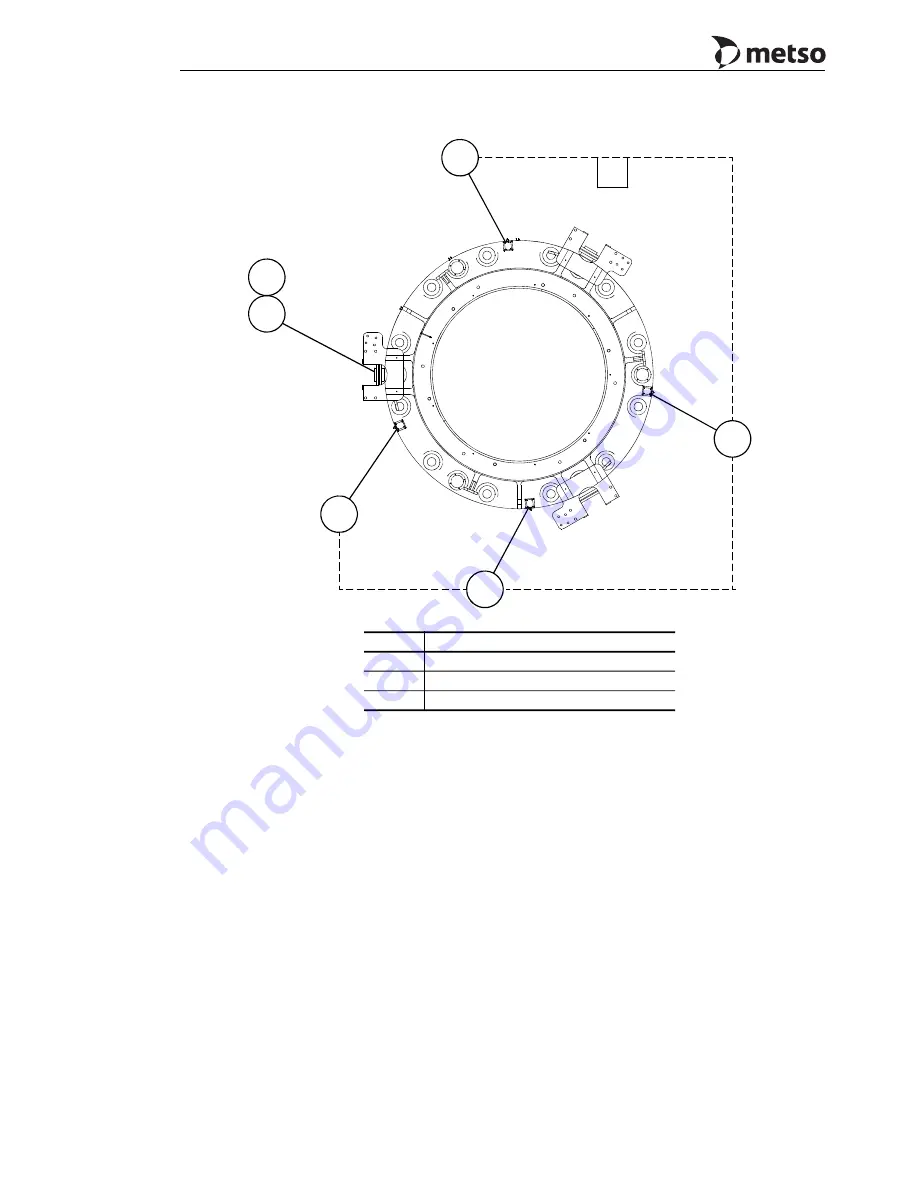

Figure 3-22 Vibration Sensor Locations (MP800 Shown)

VT

VE

n0540

VE

VE

VE

ZS

ZS

Callout

Description

VE

Vibration Sensor

VT

Vibration Transmitter

ZS

Proximity Sensor

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...