SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

3-30

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

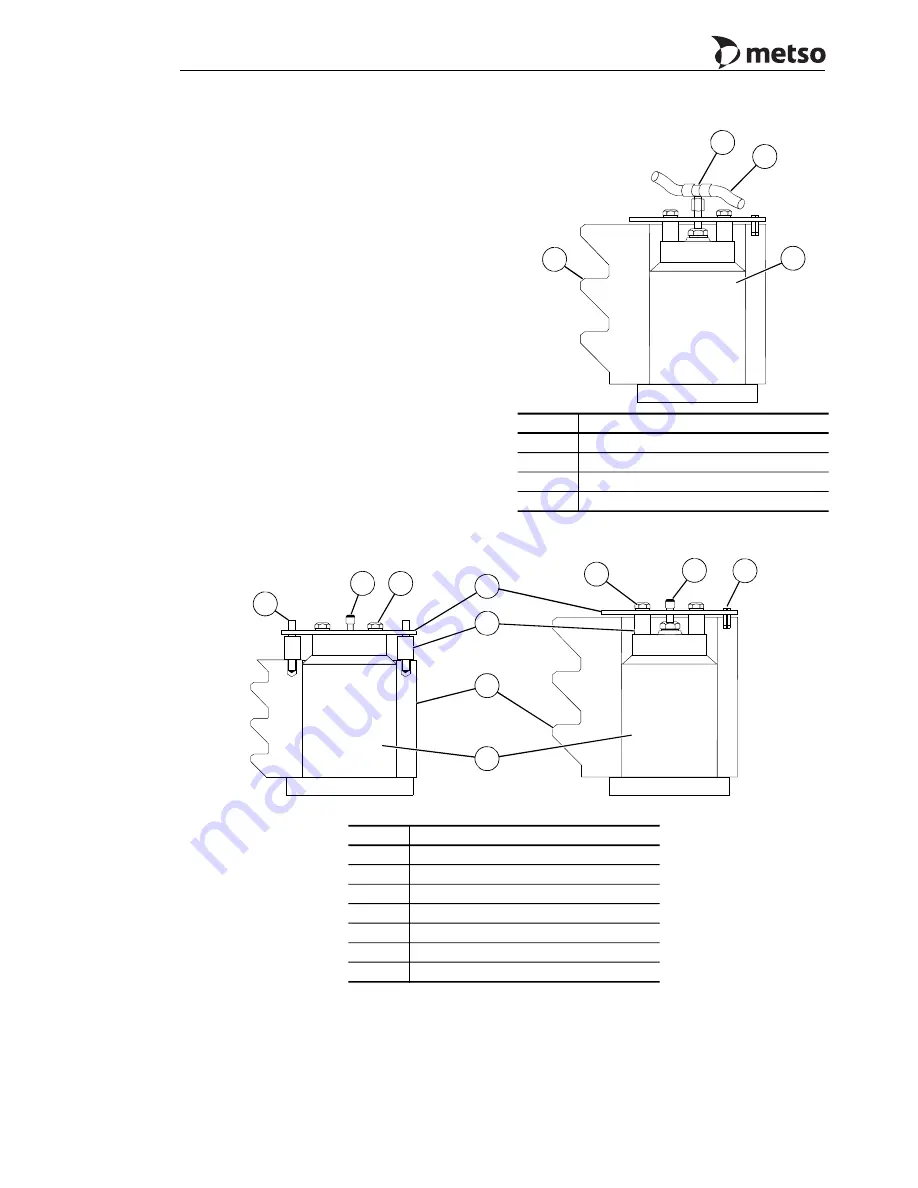

3.4.13 Clamping Cylinder Removal

Remove a faulty clamping cylinder as follows:

1. Remove the clamping ring as described in

steps 1 through 5 under

Adjustment Ring

Disassembly

in this section.

2. Set the clamping ring on wood blocking at

least 310 mm (12") off the floor.

3. Remove the hoses and tee or elbow from the

top of the cylinder. Refer to Figure 3-24.

4. Put blocking between the floor and the

clamping cylinder that is being removed.

The blocking is required so the cylinder will

not fall out of the clamp ring as the cylinder

is free to slide out of the ring when the bolts

are removed in step 5.

Figure 3-24 Clamping Cylinder Removal

Figure 3-25 Clamping Cylinder

Callout

Description

1

Tee

2

Hose

3

Clamping ring

4

Clamping cylinder

1

2

4

3

Callout

Description

1

Dowel

2

Mounting bolt

3

Mounting bracket

4

Spacer

5

Clamping ring

6

Clamping cylinder

7

Hydraulic fitting

MP800

MP1000

3

4

5

6

2

7

1

2

7

1

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...