SECTION 2 - GENERAL INSTALLATION INFORMATION

2-10

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

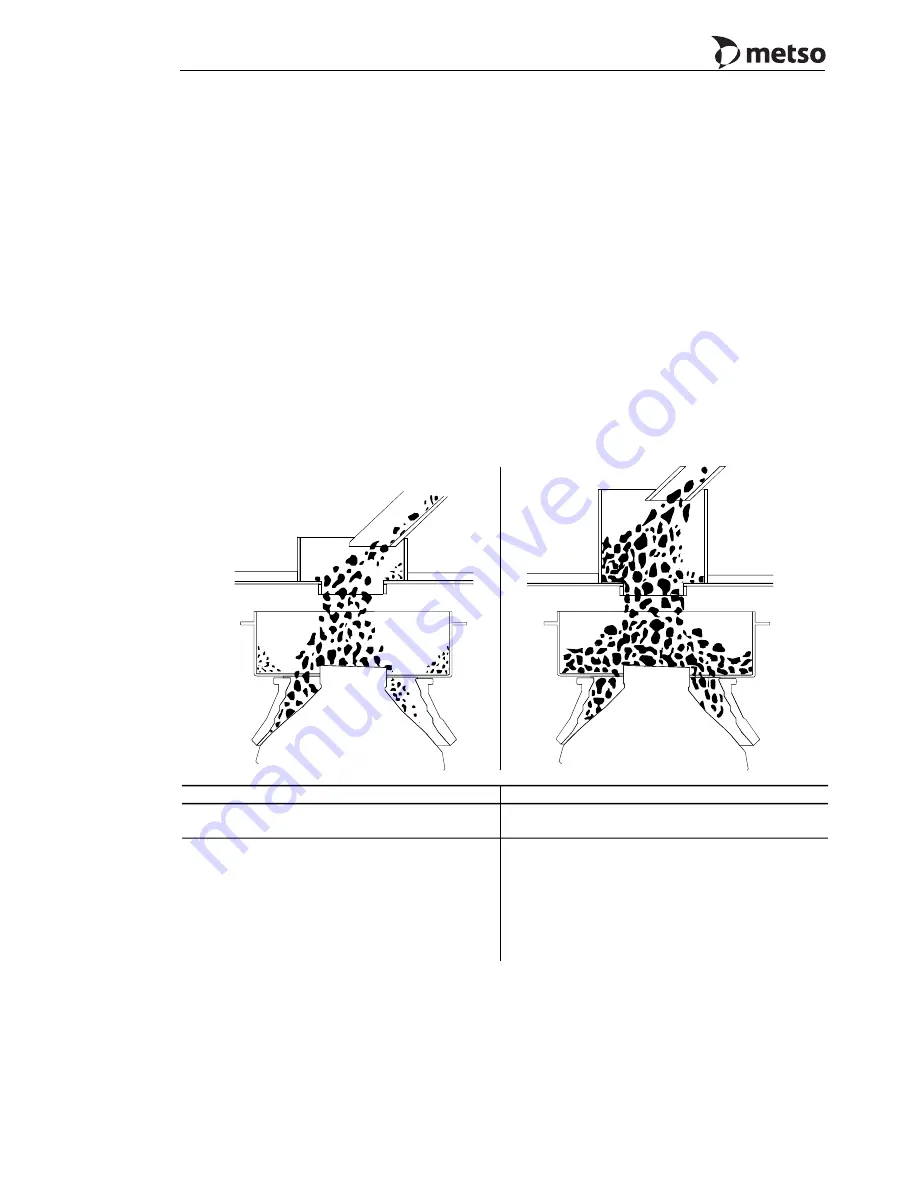

2.4 Feed Arrangement

The feed material going to the Crusher must be

controlled to keep the Crusher from overflowing, to

keep the Crusher from drawing too much power

and to keep the crushing forces within the design

limits (crushing force overload is exhibited by

adjustment ring motion relative to the mainframe;

called ring bounce). This is usually done by

locating a surge bin with a variable speed feeder

directly ahead of the Crusher so that the rate of feed

can be adjusted based on the cavity level, power

draw and adjustment ring vibration levels.

The presentation of the feed material into the

crushing cavity is also important. The feed material

should not drop more than 4' into the Crusher from

the feeder or chute. The preferred arrangement is

shown on the drawing provided as part of the

installation drawing package called “suggested feed

arrangement”. Here we show the basic design of

the feed arrangement that should include a rock

box. The feed material should overshoot the center

of the Crusher and impact into a dead bed rock box

which has a feed chute that can be located so that

the feed material will impact onto the center of the

crusher feed plate. This design provides the limit to

feed velocity required. It also provides the

centering of feed into the Crusher and will reduce

the segregation of fine versus coarse material due to

the mixing in the dead bed rock box. Refer to

Figure 2-5.

If the feed particles are very large, it may not be

possible to use a feed chute due to bridging which

can occur with the restriction of the feed chute. In

these cases, a larger diameter hole with wear

protection, can be used to direct the cascade of

material out of the rock box and onto the feed plate

of the Crusher.

Figure 2-5 Feed Arrangement

Incorrect Method of Feed

Correct Method of Feed

Here the incoming material passes through one side

of the feed opening, causing uneven distribution.

Here the incoming material falls on the feed plate

properly.

Results of uneven distribution are:

• reduced capacity

• oversize product

• excessive adjustment ring movement

• maximum bearing pressure

• maximum power consumption

Results of even distribution are:

• maximum capacity

• uniform product

• minimum adjustment ring movement

• minimum bearing pressures

• minimum power consumption

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...