SECTION 2 - GENERAL INSTALLATION INFORMATION

2-16

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

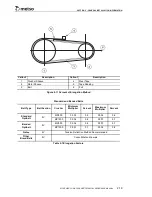

Figure 2-9 Determining Slack Side

2.8.3 Tension-Deflection Method

General method for determining amount of

deflection based on the force applied.

1. Reduce the center distance so that the belts

may be placed over the sheaves and in the

grooves without forcing them over the sides

of the grooves. Arrange the belts so that

both the top and bottom spans have about

the same sag. Apply tension to the belts by

increasing the center distance until the belts

are snug. See Figure 2-9.

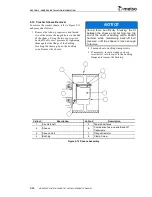

2. Place a straight edge across the top of both

sheaves. See Figure 2-10.

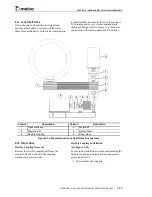

3. Measure the span length.

4. Using a tension device or spring scale at

right angles to the center of the span length,

apply a force to the device or scale great

enough to deflect one of the belts the

equivalent of 0.016 times millimeters of

span length (0.016 times inches of span

length).

Estimate the average deflection for all belts,

not concentrating on either the strongest or

the weakest belt.

5. The force should approximate the forces in

Table 2-6 for a properly tensioned drive.

These forces are for individual belts and

must be multiplied by the number of belts

per band if banded belts are being used.

Callout

Description

1

Crusher Sheave

2

Motor Sheave

3

Tight Side

4

Slack Side - Note Bow or Sag in Belt

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...