SECTION 2 - GENERAL INSTALLATION INFORMATION

2-18

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

SEE THE APPROPRIATE FOLLOWING

SECTION FOR THE CORRESPONDING

CONDITIONS REGARDING NEW OR

EXISTING BELTS AND NEW OR EXISTING

COUNTERSHAFT BUSHINGS.

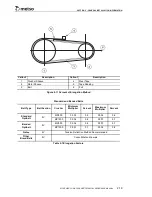

2.8.5 Tensioning Procedure for Standard

V-belts for a New Crusher Installation When

a New Countershaft Bushing with new

V-belts Has Been Installed

1. Tension the belts to the MINIMUM

TENSION shown in Table 2-6.

2. Run the Crusher WITHOUT material for a

period of 2 hours. See INITIAL START-UP

AND BREAK-IN PROCEDURE in

Section 11

.

3. After the 2 hour period retension the belts to

the INITIAL TENSION shown in Table 2-6.

4. After completing the 6 hours of reduced

load running, the belts tension should be

checked to ensure it is above the MINIMUM

TENSION shown in Table 2-6. If the tension

is not above the MINIMUM TENSION then

retension to the MAXIMUM TENSION

shown in Table 2-6.

5. After 1-4 hours of full load operation the

belts should be checked and if necessary

retensioned so that the force is between the

MINIMUM and MAXIMUM TENSION

shown in Table 2-6.

6. After 24-48 hours, it is well to check the belt

tension to see if the force on the belts is

between the MINIMUM and MAXIMUM

TENSION shown in Table 2-6. Retension if

necessary.

2.8.6 Tensioning Procedure for Standard

V-belts When a New Countershaft Bushing

Has Been Installed and Using the Existing

V-belts

1. Tension the belts to the MINIMUM

TENSION shown in Table 2-6.

2. Run the Crusher WITHOUT material for a

period of 2 hours. See INITIAL START-UP

AND BREAK-IN PROCEDURE in

Section 11

.

3. After the 2 hour period, retension so that the

force is between the MINIMUM and

MAXIMUM TENSION shown in Table 2-6.

4. After 24-48 hours, check the belt tension to

see if the force on the belts is between the

MINIMUM and MAXIMUM TENSION

shown in Table 2-6. Retension if necessary.

2.8.7 Tensioning Procedure for Standard

V-belts When New V-belts Have Been

Installed With Existing Countershaft

Bushing

1. Tension the V-belts to the INITIAL

TENSION shown in Table 2-6.

2. After 1-4 hours of full load operation, the

belt tension should be checked to ensure it is

between the MINIMUM and MAXIMUM

TENSION shown in Table 2-6. Retension if

necessary.

3. After 24-48 hours, it is well to check the belt

tension to see if the force on the belts is

between the MINIMUM and MAXIMUM

TENSION shown in Table 2-6. Retension if

necessary.

2.8.8 Retensioning Procedure for Standard

V-belts Using Existing V-belts

1. Retension the belts so that the force on the

belts is between the MINIMUM and

MAXIMUM TENSION shown in Table 2-6.

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

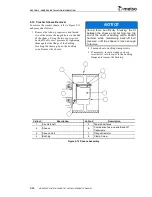

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...