SECTION 2 - GENERAL INSTALLATION INFORMATION

2-22

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

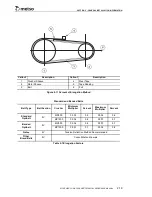

Figure 2-12 End Float - V-belt Drive

2.10 Checking End Float

If the countershaft box was shipped completely

assembled, the end float was set correctly at the

factory; but, as it is important for the proper

operation of the Crusher, recheck the end float. The

countershaft must be free to move in and out. See

Figure 2-12 and check end float as follows:

1. Pull the pinion end of the countershaft until

the oil flinger is tight against outer

countershaft bushing flange.

2. Use a feeler gauge to measure the gap (end

float) between the pinion and countershaft

bushing. The end float should be between

1.5 mm (.060") and 0.8 mm (0.30"). If not,

obtain correct end float as described under

COUNTERSHAFT BOX ASSEMBLY in

Section 4

.

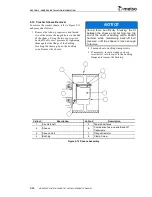

2.11 Crusher Sheave Installation

(V-belt Drive)

To install a crusher sheave with a removable

bushing, see Figure 2-13 and proceed as follows:

1. Refer to the oil piping drawing and install

all oil piping.

2. Remove the split tapered bushing from the

sheave by unscrewing the combination

take-up and back-off capscrews, if bushing

has not been installed.

3. Check that the tapered surface and bore of

the bushing, the tapered bore of the sheave

and the countershaft, are clean and free of

burrs, scratches and all foreign matter, such

as paint, dirt and lubricants.

4. Gently tap the sheave key into the

countershaft keyway with a light hammer, if

key and bushing has not been installed.

Callout

Description

Callout

Description

1

Countershaft

8

Tight (no gap)

2

Inner countershaft bushing

9

No clearance (tight)

3

Outer countershaft bushing

10

Measure end float here

4

Oil flinger

• 1.5 mm (0.060") to

5

Sheave bushing

• 0.8 mm (0.030")

6

Sheave key

11

Set collar (for direct drive or shipping)

7

Clamp screw

12

For Direct Drive or Shipping

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...