SECTION 2 - GENERAL INSTALLATION INFORMATION

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

2-23

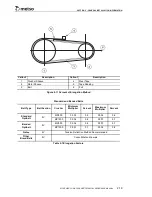

5. Loosen the clamp screw and slide the

bushing onto the countershaft aligning the

sheave key and keyway. If necessary, insert

a wedge (example: screwdriver) into

bushing slit to aid in installation of bushing.

Tighten clamp screw when bushing is tight

against oil flinger.

6. Move countershaft in and out to recheck end

float. See CHECKING END FLOAT earlier

in this section.

7. Slide the sheave over the bushing being

careful to keep the bolt holes lined up with

the tapped holes in the bushing flange.

8. Insert the take-up bolts through the bolt

holes and alternately tighten each bolt a

small amount until all bolts are tightened to

a final torque value identified in Table 2-8

based on the size of the sheave bushing. Do

not lubricate the bolt threads or the tapped

holes. When the sheave is finally positioned

a clearance of approximately 10 mm (.375")

should exist between the face of the sheave

hub and the flange of the bushing. No

attempt should be made to take up this

clearance as this clearance assures the

proper fit and grip between sheave bushing

and countershaft. Follow the torque

requirements closely; overtightening the

take-up bolts could cause the sheave to

crack.

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

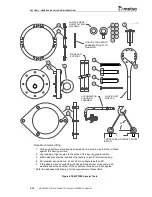

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...