3. Installation

page 18

ELC PE22B-PE35B V1.0-05.19-GB

Subject to technical alterations

3.5.1.

Setting up the PROFIBUS address

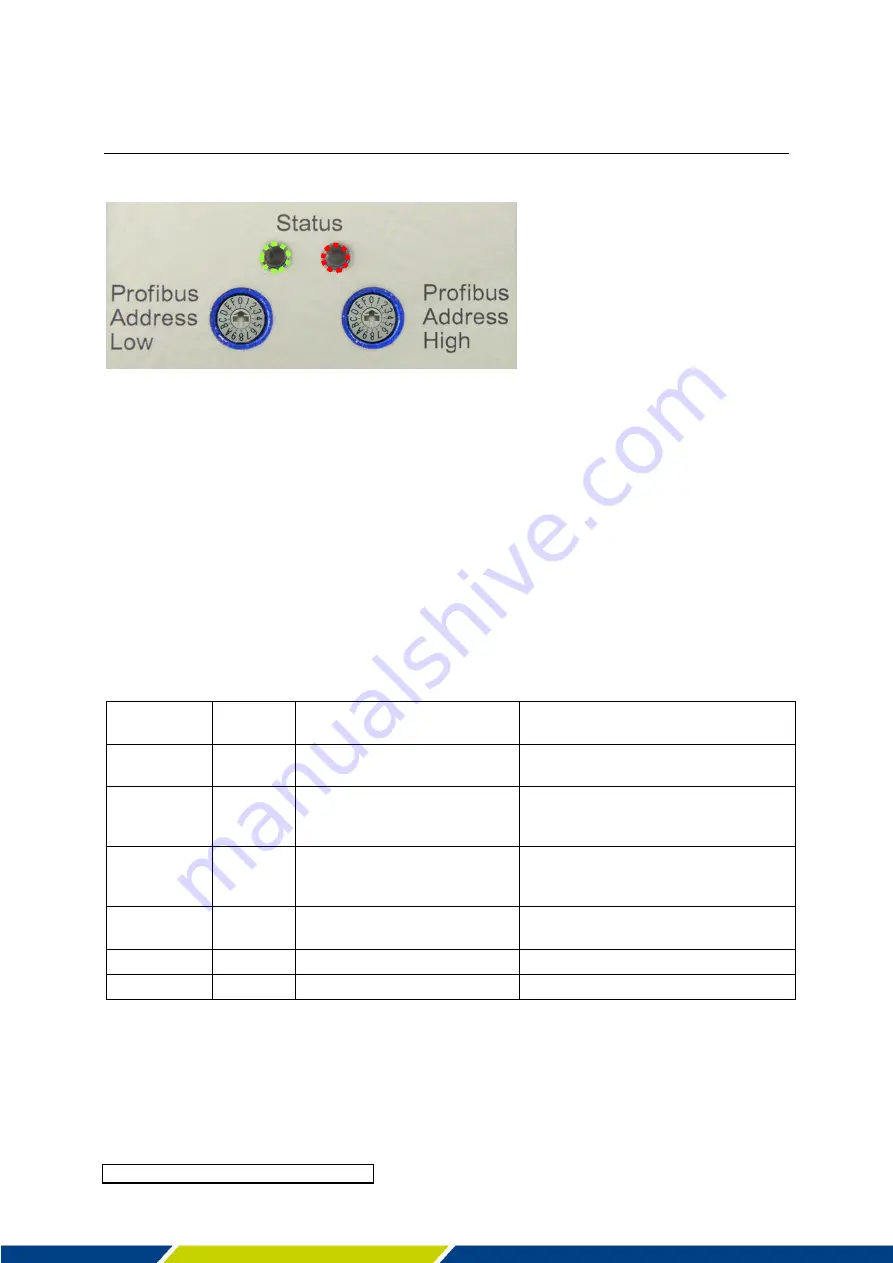

Fig. 7:

LED status (green left, red right) and rotary coding switch for low and high nibble

The PROFIBUS address must be set using the rotary coding switches.

The address space extends from 01_hex to 7D_hex (corresponding to 1 to 125), whereby low

and high nibble are allocated according to Fig. 7. Each address may be used only once per

installation.

The address is adopted when current is applied to the ELC (paragraph 4.2). If the appliance is

already under power supply, it must first be disconnected.

3.5.2.

Checking the PROFIBUS connection

The Status-LED (Fig. 7)

may be used to check the successful connection of ELC and Master

and furthermore the existence of an error (ELC not ready for operation):

LED green

(left)

LED red

(right)

Status

Corrective action

on

off

ELC ready for operation,

PROFIBUS-connection ok

blinking

off

ELC ready for operation, no

PROFIBUS-connection

Check plug contact, bus termination (see

paragraph 3.3.3), check address and

panel-programming.

on

blinking

ELC not ready for operation,

PROFIBUS-connection ok

The error cause detected by the ELC may

be read out in the Error Register (see

paragraph 5.4.1)

blinking

blinking

ELC not ready for operation, no

PROFIBUS-connection

Detach ELC from mains and restart.

off

blinking

Internal error.

Detach ELC from mains and restart.

off

off

Internal error or no supply.

Check power supply