18

DO NOT ATTEMPT TO LIFT THE SPREADER BY THE CENTER LIFT OR CORNER LIFT HOOKS

WITH MATERIAL IN THE SPREADER.

BEFORE BEGINNING ANY MAINTENANCE ON SPREADER, DISCONNECT SPREADER

BATTERY LEADS.

1.

Grease idler bearings on idler shaft takeup assembly, outboard bearing on gearbox output shaft, and

lower spinner bearing every ten hours of operation.

2.

Grease input shaft bearing on gearbox every fifty hours of operation.

CAUTION!

Over greasing may

cause seal damage. The gearbox must be filled to oil level plug with SAE 90 gear type lubricant. Keep

breather plug clean.

3.

Drag chain slack on V-boxes should be checked periodically and taken up if distance between center line

of rear sprocket and point where chain contacts lower flange on longitudinal is less than eight (8) inches.

CAUTION!

Over tightening conveor chain can cause serious drive train problems. Above distance must

not exceed 20 inches.

4.

If the spreader is equipped with a gasoline engine, it should be maintained per engine manufacturer's

instruction. (Instructions and parts book is enclosed.)

5.

V-belt tension must be maintained. The v-belt can be tightened by loosening engine hold-down bolts and

sliding engine as required.

CAUTION!

Over tightening of v-belt may damage gearbox.

6.

Roller chain tension must be maintained. It is adjusted by loosening the spinner mounting bearings and

sliding the bearings. Make sure the spinner shaft is straight up and down before retightening. Oil chain

often and at end of season.

7.

When the box is not in use, it should be washed out. If the box is put in storage, all surfaces should be

oiled or painted after washing.

8.

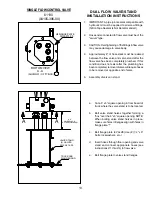

For HYDRAULIC SPREADERS, maintain oil level three fourths (3/4) full in reservoir with clean high grade

non-foaming hydraulic oil; recommended viscosity 100-200 SSU. Operating temperature should be limited

to 180°F. Replace filter cartridge No. 62382 (04104 005 00) at least twice a year.

9.

If chain becomes stuck or "froze" to the floor to the point where the clutch cannot pull the load, never

attempt to free chain using a pipe wrench or any other tool on the output shaft. The gearbox is designed

to accept torque from input shaft only. Trying to turn output shaft will strip the gears, thus voiding the

warranty.

10.

To minimize problems and extend the life of the Electric Clutch, the following is highly recommended.

a.

Before starting unit, make sure the drag chain is free (not stuck or "froze" to the

floor). If the drag chain is stuck, this can cause the clutch to burnup.

b.

After the using season is over, remove clutch from unit, and clean thoroughly.

c.

After cleaning, coat both mating surfaces of the clutch with oil or light weight

grease.

NOTE:

The Oil or Grease must be removed prior to the next using season.

WARNING

MAINTENANCE