DIAGNOSTIC FLOW CHART FOR

E-57 & E-60 ELECTRO LIFT

®

UNITS

WITH TOUCH PAD

These charts are intended to be used as an aid in diagnosing problems on the Electro Lift

®

units. They are not a substitute for factory

training and experience. Be certain to read the General Information and Testing Tips sections before attempting any troubleshooting.

IMPORTANT: Maintenance and repairs must be performed with the moldboard on the ground.

General Information

Before any troubleshooting is started, make certain the following conditions are met.

1.

The moldboard is pointing straight ahead. This can often be done by coupling the left cylinder into the right cylinder and

pushing the moldboard by hand.

2.

The power angling cylinders must be installed correctly on to the A- frame. The left cylinder (Driver’s side) has a hose attached

with a male half of a coupler at the end; the right cylinder (Passenger side) has a hose attached with a female half of a coupler

at the end.

3.

The solenoid coils must be on their proper valve. (See drawing below).

TESTING TIPS

Many tests do not require removing the Electro Lift

®

unit from the vehicle. However, more thorough testing can be performed using

the Meyer Test Stand which allows direct pressure and amperage readings.

1.

Using a screwdriver or other small tool to check for magnetism of the solenoid coils “A”, “B” and “C”. Place the tool on the nut

securing the coil and have an assistant operate the switch. You should feel strong magnetic attraction.

2.

Use a test light or volt meter to determine whether there is power at the harness or switch.

3.

When determining AMP draw of the motor, always obtain the highest value possible, i.e, at maximum raise or maximum angle

with motor running.

4.

Proper rotation for the 4-1/2” motor (Fenner/Iskra) is clockwise by looking at the motor shaft from the bottom of the motor.

5.

The pump shaft of a good pump can be turned smoothly using two fingers. If it can’t be turn easily, the pump is too tight and

must be replaced.

6.

Pump pressure can be measured at an angle hose (note pressure at full angle) or in the pressure filter port (an adaptor is

necessary for the filter port).

7.

Flush the complete system including unit, hoses and power angling rams with a non wax (Napthenic) oil / cleaner. If kerosene

(Parrafinic) is used to flush the system, the system must be flushed again to remove any kerosene with a (Napthenic) based

oil / cleaner that is wax free.

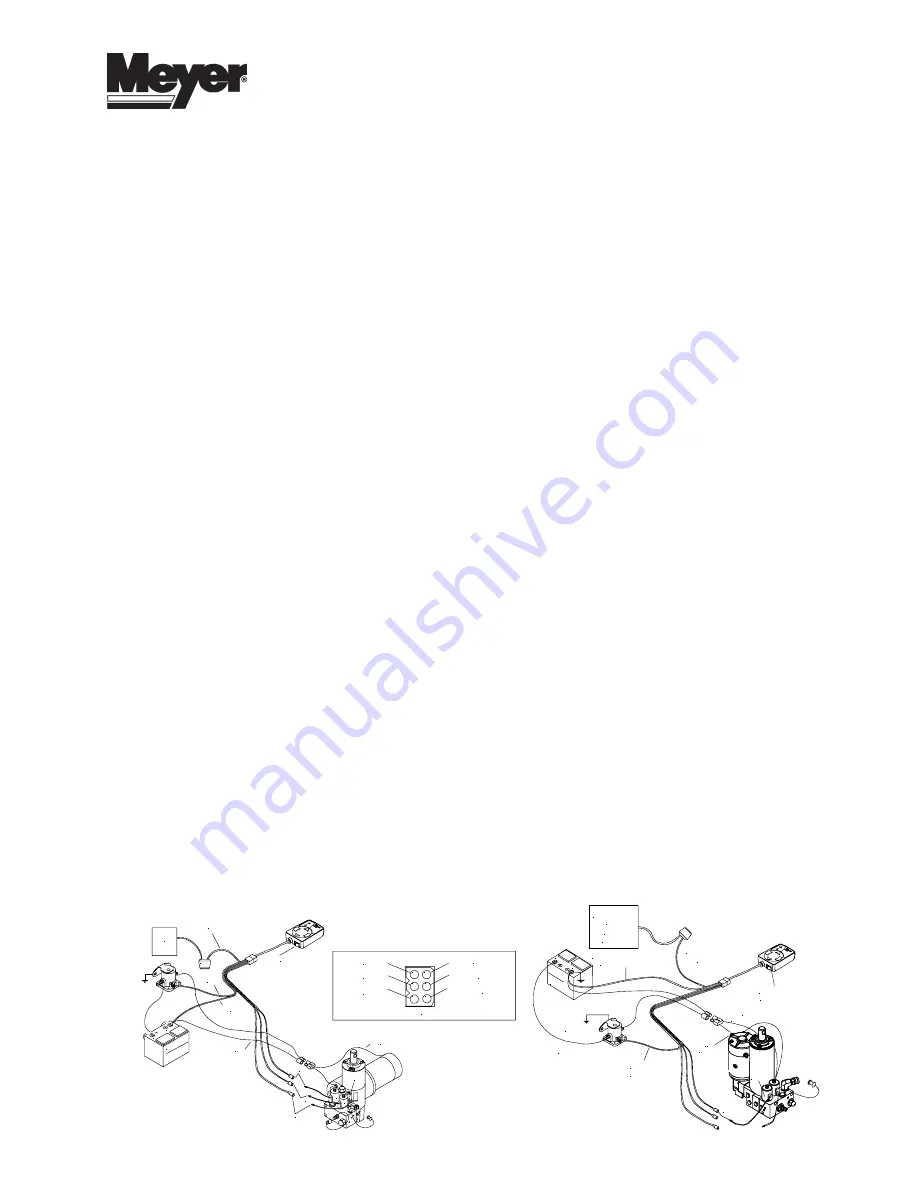

BA

TTE

RY

PO

S

NE

G

10A

1

2

3

4

5

6

TO "A" SOLENOID

(BLACK WIRE)

TO "C" SOLENOID

(GREEN WIRE)

TO "B" SOLENOID

(RED WIRE)

TO MOTOR SOLENOID

(WHITE WIRE)

POWER TO SWITCH

(BLUE WIRE)

GROUND

(ORANGE WIRE)

END OF TOUCH PAD HARNESS

FUSE

PANEL

ON / OFF

SWITCH

POWER TO SWITCH

BLUE WIRE

WHITE

WIRE

SWITCH GROUND

ORANGE WIRE

GROUND

POWER

RED

B

GREEN

BLACK

C

A

E-60 & E-60H

The

current 22154 Electro-Touch Control

has been redesigned.

The Touch Pad now has raised buttons and its circuitry has been changed

from analog to digital, functions have not changed. For troubleshooting for

power at the solenoids do not disconnect wires. To check for power, prick the

wire through the insulation for testing. The

Electro-Touch Control

knows when

a short or an open connection occurs and will go into overload mode for the

function being activated. To reset the Touch Pad turn the switch on and off. The

Electro-Touch Control

will not operate if not wired properly as per the

installation instructions (1-690 & 1-759).

ON / OFF

SWITCH

POWER TO SWITCH

BLUE WIRE

WHITE

WIRE

SWITCH GROUND

ORANGE WIRE

GROUND

RED

POWER

"B"

DRA

IN

DRA

IN

D1

NEGATIVE

A2

POSITVE

BAT

TER

Y

POS

NEG

10

A

FUSE

PANEL

Ignition Switch

"ON"

E-57 & E-57H