OPERATION

LOADING

CAUTION

:

TO PREVENT DAMAGE TO AU-

GERS, SPINNERS, AND DRIVE LINES, FOREIGN

OBJECTS (STONES, CONCRETE, TIMBER, METAL

OR LARGE FROZEN CHUNKS OF MANURE)

SHOULD NEVER BE LOADED INTO THE

SPREADER.

DANGER

:

NEVER ENTER THE SPREADER

BOX FOR ANY REASON WITHOUT FIRST DISCON-

NECTING PTO SHAFT FROM TRACTOR. DO NOT AL-

LOW OTHERS IN THE BOX. ROTATING AUGERS CAN

CRUSH AND DISMEMBER. FAILURE TO HEED MAY

RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

CAUTION

:

DO NOT USE JACK EXCEPT

WHEN SPREADER IS EMPTY. JACK WILL NOT

SUPPORT ADDED WEIGHT. UNBALANCED

WEIGHT MAY RESULT IN UNEXPECTED “TIP UP”

OF SPREADER.

Before loading, especially in freezing weather, make

sure the augers and spinners are free to rotate and the

flow control rear gate moves freely up and down.

Manually latch close the trip pan doors at rear of

spreader.

Check and be sure that the flow control rear gate is

completely closed before loading.

When the spreader is parked for loading, shift the trac-

tor to neutral or park and set the brakes. The moisture

content of the manure will determine how full the

spreader can be loaded so that no manure spills out.

You will probably be able to load solid manure at least

level with the top of the box while semi-liquid and liquid

manure will have to be less than full in the spreader

box. It is unlawful to allow manure to splash or leak

onto public roads.

A liquid manure kit is available for installation around

the top of the box on your spreader which will aid in

the containment of liquids.

UNLOADING

WARNING

:

MAKE CERTAIN EVERYONE IS

CLEAR OF SPREADER BEFORE APPLYING

POWER. FAILURE TO HEED MAY RESULT IN SE-

RIOUS PERSONAL INJURY OR DEATH.

DANGER

:

KEEP AWAY AND KEEP OTHERS

CLEAR OF ROTATING SPINNERS AT REAR OF

SPREADER. SERIOUS INJURY OR AMPUTATION

COULD RESULT. FAILURE TO HEED MAY RESULT

IN SERIOUS PERSONAL INJURY OR DEATH.

When you are ready to begin spreading application on

the field, open the hydraulic flow control rear gate and

slowly engage the tractor PTO clutch. This can be

done while traveling forward to avoid a heavier appli-

cation of liquid manure at the edge of the field than de-

sired.

For liquid and semi-liquid manure, the application rate

can be controlled by the amount the flow control rear

gate is opened. The height of the gate indicator bar

above the rear edge of the box will provide a ready ref-

erence for the amount of opening. See figure 5. For

solid manure (dry, pen-packed or manure containing

long straw or hay) the flow control rear gate MUST be

completely open since this material is not free flowing.

Model V-Max

—12—

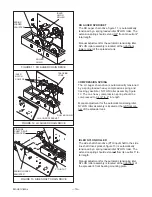

FIGURE 5. FLOW CONTROL REAR GATE

GATE INDICATOR

Summary of Contents for V-MAX 2636 Operators

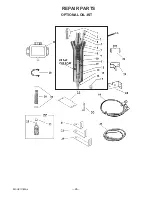

Page 24: ...Model V Max 24 REPAIR PARTS OPTIONAL OIL KIT 35 ...

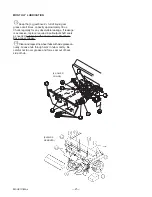

Page 26: ...Model V Max 26 FRONT SHIELD SIDE SHAFT DRIVE ...

Page 34: ...Model V Max 34 BOX AUGERS SIDE SHAFT ...

Page 36: ...Model V Max 36 UNLOADING GATE TRIP PAN DOORS Prior to 08 Serial Nos ...

Page 38: ...Model V Max 38 SPINNERS GEARBOX SHAFT DRIVE PRIOR TO 08 SERIAL NOS ...

Page 42: ...Model V Max 42 OPTIONAL THIRD AUGER Items 10 and 11 are used on two auger units only ...

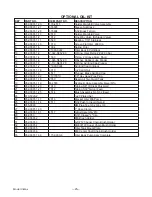

Page 57: ...Model V Max 57 ...

Page 58: ...Model V Max 58 ...

Page 59: ...Model V Max 59 ...

Page 60: ...E ...