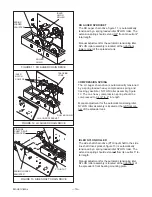

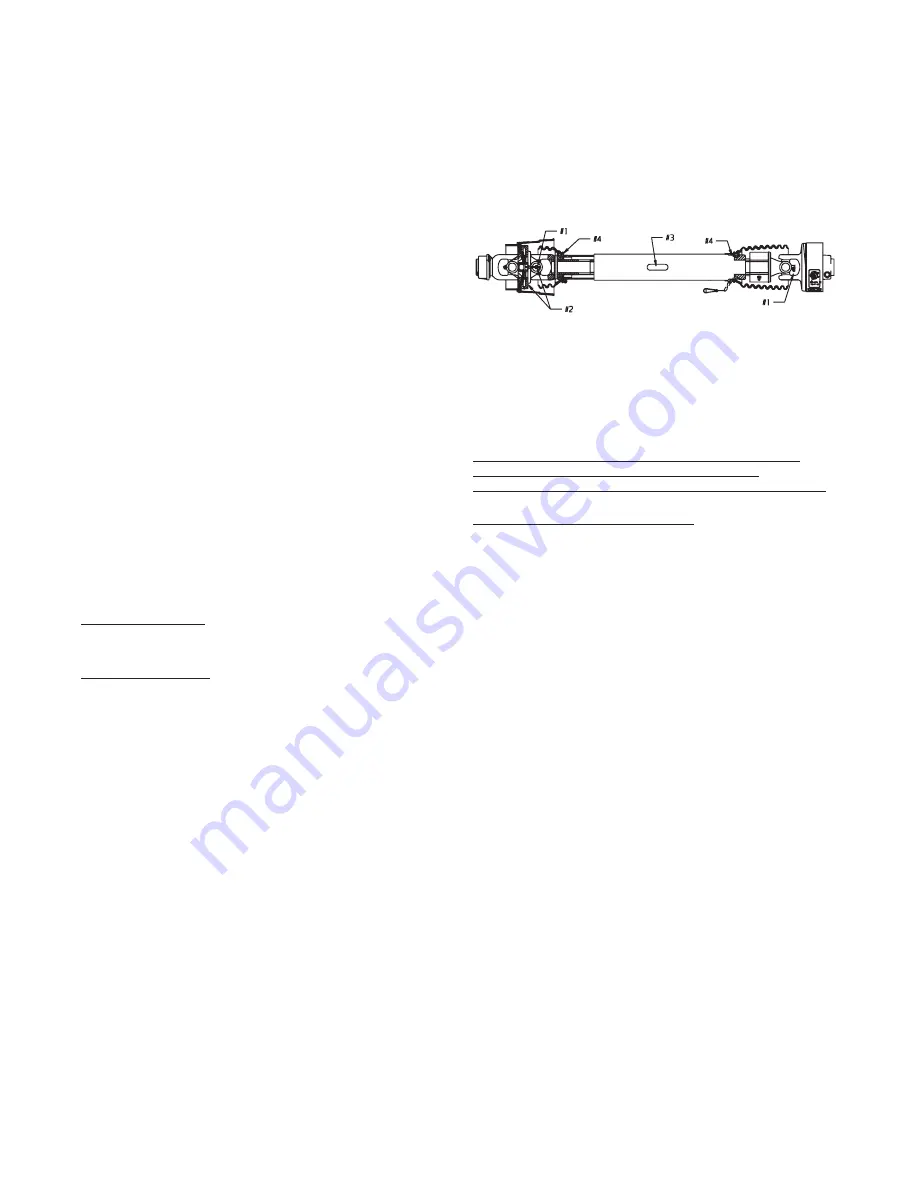

Adjust the drawbar at 13-17” above the ground. Ex-

tend or shorten the drawbar so horizontal distance

from end of tractor PTO shaft to center of hitch pin

hole is 14” for 540 RPM 1-3/8-6 spline, (16” for op-

tional 1000 RPM 1-3/8-21 spline). Secure the drawbar

so the hitch pin hole is located directly below the PTO

drive line. PTO adapters are not recommended as

damage to the drive line may occur. A hitch pin with a

minimum diameter of 1” and bottom retaining pin is

recommended.

AN IMPROPERLY LOCATED HITCH POINT MAY

CAUSE DAMAGE TO THE UNIVERSAL JOINTS OF

THE PTO DRIVE SHAFT. CONFORMING TO THE

DRAWBAR AND PTO RELATIONSHIP SHOWN ON

FIGURE 1, PAGE 8 WILL ENSURE THAT THE PTO

DRIVESHAFT WILL NOT BECOME OVER

EXTENDED. USE THE CORRECT SETTING FOR

14” - 540RPM 1 3/8-6 or 16” - 1000RPM 1 3/8-21.

WITH INITIAL HOOK-UP TO YOUR NEW MEYER

SPREADER TEST PTO TRAVEL BY TURNING

EQUIPMENT IN BOTH DIRECTIONS OBSERVING

THE MINIMUM AND MAXIMUM TRAVEL

DIMENSIONS AS SHOWN PER DRAWING ON

FIGURE 6, PAGE 15.

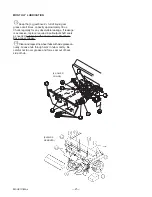

LUBRICATION

LUBRICATION

A high quality Lithium Base Grease should be used

PRIOR TO USE

A. Using the CV Zerk (Key #2) place 20 pumps of

grease into the CV center housing. This should

be done with the drive line / CV as straight as

possible.

B. Slowly articulate the double joint through its

maximum joint angle several times.

C. Return the CV joint to its straight position and

insert additional grease into the CV Zerk (Key

#2) until grease is evident around the housing

and center sliding disk.

NORMAL OPERATION

A. Lubricate the following items after every eight

(8) hours of operation. If short rows and

frequent turning or other demanding conditions

exist, lubricate at four (4) hour intervals.

1.

Cross and bearings (Key #1)-Add grease

until it is purged around the seals.

2.

CV center housing (Key #2)-Add grease

until it is evident around the center sliding

disk.

3.

Telescoping members (Key #3)-Add

grease until it adequately covers the

sliding members. Take apart

occasionally to make sure adequate

lubrication is being added.

4.

Shield bearings (Key #4)-Add 2-3 pumps.

FAILURE TO FREQUENTLY GREASE THE CV

CENTER HOUSING AND TELESCOPING

MEMBERS WILL REDUCE THE LIFE OF THE CV.

MAINTENANCE INFORMATION

It is extremely important to follow the maintenance

guidelines. If telescoping members become hard to

slide during normal operation, it is recommended the

shaft be taken apart, cleaned with solvent and

re-coated with grease before re-assembling. As a

minimum it is important this be done after each season

of use.

Model V-Max

—16—

FIGURE 7. PTO DRIVE LINE

Summary of Contents for V-MAX 2636 Operators

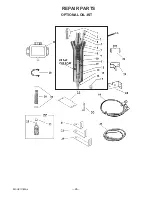

Page 24: ...Model V Max 24 REPAIR PARTS OPTIONAL OIL KIT 35 ...

Page 26: ...Model V Max 26 FRONT SHIELD SIDE SHAFT DRIVE ...

Page 34: ...Model V Max 34 BOX AUGERS SIDE SHAFT ...

Page 36: ...Model V Max 36 UNLOADING GATE TRIP PAN DOORS Prior to 08 Serial Nos ...

Page 38: ...Model V Max 38 SPINNERS GEARBOX SHAFT DRIVE PRIOR TO 08 SERIAL NOS ...

Page 42: ...Model V Max 42 OPTIONAL THIRD AUGER Items 10 and 11 are used on two auger units only ...

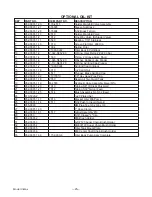

Page 57: ...Model V Max 57 ...

Page 58: ...Model V Max 58 ...

Page 59: ...Model V Max 59 ...

Page 60: ...E ...