Page 10

Model 390

PRE-OPERATION

GENERAL

Read the entire Owner's Manual before attempting to

operate this manure spreader. Before attempting any

maintenance or repairs; always be sure all rotating

parts have stopped and that the tractor is shut off, dis-

connect the PTO, relieve all hydraulic pressure and

disconnect hydraulic hoses.

WARNING

NEVER OPERATE SPREADER WITH ANY GUARDS

OR SHIELDS REMOVED. FAILURE TO HEED MAY

RESULT IN SERIOUS PERSONAL INJURY OR

DEATH.

1. Completely lubricate the unit as described in the

LUBRICATION Section.

2. Check and tighten the wheel lug nuts if required.

3. Check and maintain the tire pressure according to

the manufacturer’s recommendation.

4. Check the entire unit for loose bolts, damaged or

loose hydraulic fittings and hoses or other damaged

parts.

5. The tractor half of the PTO drive shaft assembly

must be locked securely to the tractor output shaft.

TRACTOR HOOKUP

Tractor Requirements:

1. The spreader is designed to be operated by a 540

rpm PTO tractor output. In addition, 1 set of tractor re-

mote hydraulic ports are required, to operate the apron

drive and a second set of ports will be required for an

optional hydraulic end gate.

2. The PTO drive shaft assembly is designed to oper-

ate with tractors conforming to the industry standard

shown on Figure 1 for 540 RPM PTO output.

Tractor Size

1. The spreader does not have brakes. Towing the

spreader must be done safely. The ASAE (American

Society of Agricultural Engineers) specifies that the

towing vehicle should weigh at least 2/3 as much as the

loaded implement to be reasonably safe towing at

speeds up to 20 mph. This (20 mph) is also the maxi-

mum recommended towing speed for the spreader.

2. The loaded weight of your spreader will naturally

vary with the moisture of the manure and you must

consider that for your conditions. The loaded weight

capacities as specified by the spreader manufacturer

are as follows:

Tractor Towing Size Requirements:

Use the following chart for calculating the minimum

tractor weight.

MODEL

(struck

level)

SPREADER EMPTY

LOAD = GW

MINIMUM TRAC-

TOR WEIGHT UP

TO 20 MPH

390

(245 cu ft)

5540 + _______ = _______

2/3 of spreader

gross weight

Material Estimated Weight Per Cubic Foot

Material

lbs / Cu. Ft.

Lime Sludge

110-115 LBS.

Dry Feedlot Manure

63-65 LBS.

Chicken Litter

63-65 LBS.

Cake Sludge

62-65 LBS.

Semi-Solid Manure

58-60 LBS.

Pen Packed Manure

30-35 LBS.

Liquid Manure

63-65 LBS.

SOURCE: ASAE

NOTE:

HEAPED LOADS HAVE SIGNIFICANTLY

HIGHER CAPACITIES RESULTING IN INCREASED

WEIGHT AND HIGHER CENTER OF GRAVITY, RE-

QUIRING EXTRA PRECAUTION DURING OPERA-

TION.

Tractor Hookup

1. Hook the spreader hitch to the tractor drawbar with

secured hitch pin conforming to the pin hole size in the

spreader hitch.

Drawbar.tif

FIGURE 1. TR ACTOR DR AWB AR & PTO

SPECIFIC ATION

Summary of Contents for 390 Tandem

Page 18: ...Page 18 Model 390 REPAIR PARTS MAIN FRAME AND BOX PARTS...

Page 22: ...Page 22 Model 390 FRONT AND SIDE DRIVE SHAFT AND RELATED PARTS...

Page 24: ...Page 24 Model 390 APRON AND BEATER DRIVE CLUTCH AND RELATED PARTS RearHydDrive 300 tif...

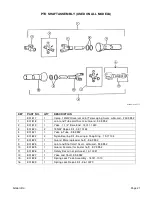

Page 34: ...Page 34 Model 390 HYDRAULIC SYSTEM PARTS HydraulicParts 390 tif...

Page 38: ...Page 38 Model 390 APRON DRIVE GEAR BOX HO382 GearboxParts 390 tif...

Page 40: ...Page 40 Model 390 APRON DRIVE HYDRAULIC MOTOR HydMotorOpt 300 tif...

Page 42: ...Page 42 Model 390 APRON AND RELATED PARTS ApronParts 390 tif...

Page 44: ...Page 44 Model 390 BEATERS AND RELATED PARTS...

Page 50: ...Page 50 Model 390 This Page Intentionally Blank...

Page 51: ...Model 390 Page 51 This Page Intentionally Blank...