19

Turning the leg supports to the

side

Benefits:

Easy transfer into and out of the

wheelchair.

Leg region free, no stumbling.

Close access to cupboards possible.

Reduced length of the wheelchair,

for storing the wheelchair.

Handling:

Switch off the wheelchair and

move the brake release lever to the

drive position. This prevents

the wheelchair from rolling away

accidentally.

Remove lower leg strap, if present.

Remove both feet from the foot-

plates.

Fold up footplates (fig. 9).

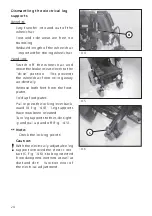

Pull or press the locking lever back-

ward (A, fig. 10). Leg supports

have now been released.

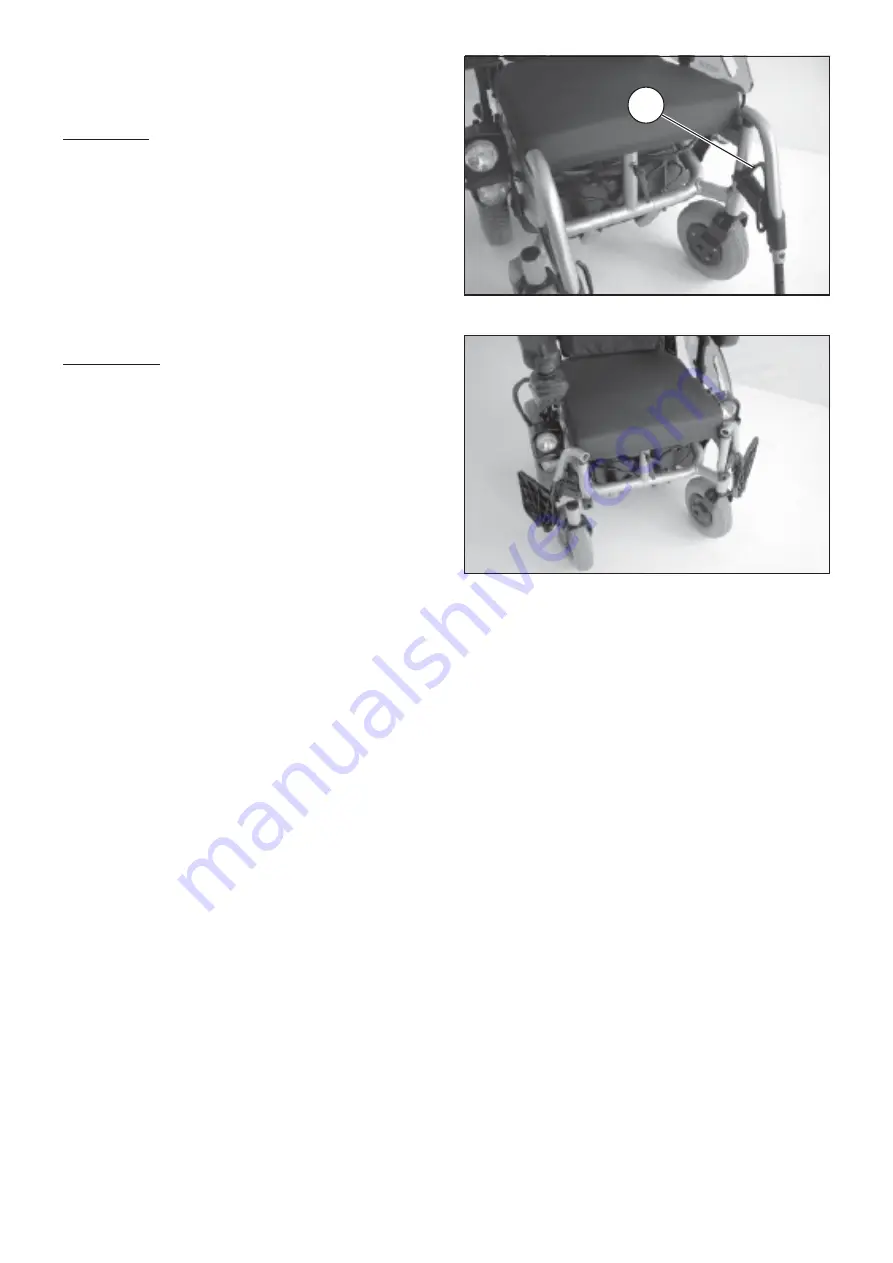

Turn leg support to the side (fig.

11).

!

Caution:

Swivelled-away leg stump supports

are automatically unlocked and

can easily fall off. Note this when

handling (e.g. transport).

After replacing the leg supports do

not forget to check that they are

securely locked in place! Check

the locking points!

10

11

A