29

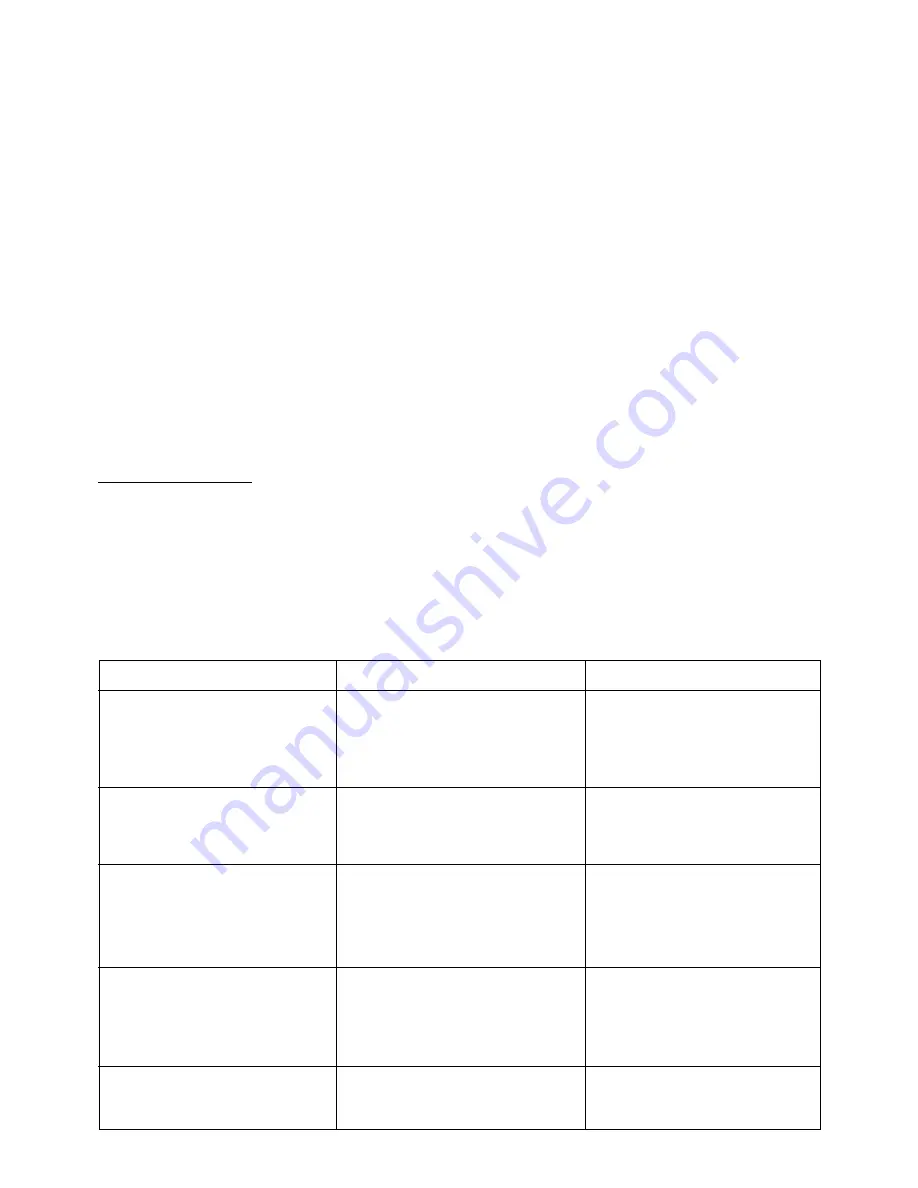

Fault

Cause

Clearance

LED / LCD display does not light up

after the wheelchair has been

switched on.

Wheelchair does not move forward.

Lighting not active.

Warning light [26] blinks when the

hazard warning indication is not

switched on.

Main fuse defective.

The brake release lever is set to push

mode.

Bulb defective.

Lighting or electronics fuse defective.

Malfunction in the electronics.

The main fuse for the battery circuit is

defective (blade-type fuse) or not insert-

ed deep enough.

Replace fuse.

Move the brake release lever to drive

mode.

Fit new bulb.

Replace defective fuse.

Send to a specialist workshop for re-

pair.

Change the blade-type electric fuse or

insert it properly.

Brake symbol is lit.

Overheated electronics.

Switch off wheelchair and

switch on again after a cooling.

SERVICE

FUSES

Replacing a defective safety

fuse

!

Attention:

Only replace the safety fuse with a

safety fuse of the same type!

New safety fuses are available at all

petrol stations.

If the safety fuse blows again, take the

battery to your specialist dealer for re-

pair.

Main safety fuse for the

battery circuit:

The blade-type fuse for the battery cur-

rent is located in the fuse holder under

the seat (A, Fig. 5).

Pulling out the main fuse during driving

causes an immediate stopping of the

wheelchair! – Danger of accidents!

SPRINT GT, model 2.593

Main fuse for 6 and 10 km/h versions:

60 amp maxi-fuse (light-blue, blade-

type).

FAULT CLEARANCE

FAULT CLEARANCE

If treated properly, your wheelchair will

not malfunction. To ensure that your

wheelchair gives you many years of

service, especially if it is your first elec-

tronic wheelchair, we have listed possi-

ble faults and remedial action to be tak-

en in the following table.

We recommend that an inspection is

carried out every 2 years to permit the

early recognition and clearance of faults

which are not listed in the table. The

following inspection certificates should

then be stamped by your specialist deal-

er.

!

Attention:

Work on the internal mechanics of

the joystick and electronic parts

should only be carried out by a spe-

cialist workshop .

The mechanics of the joystick should

never be oiled but completely re-

placed!

Other blade-type fuses

The following blade-type fuses are lo-

cated in a row on the adapter board in

the adapter box (A, Fig. 54):

– 20A charging fuse

– 2A

power electronics control

– 7,5A electrical adjustment

– 5A

lighting

Battery charging fuse

Charging fuse located in the control box

15A ø6x32mm miniature fuse (glass

tube).