MFJ-1775 Rotatable Mini-Dipole

Instruction Manual

7

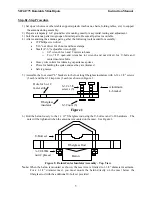

11) Install the 6-32 screws in all rings of both loading coil assemblies, loosely holding them in place with

their associated nuts. Position the screws so the threaded ends of the screws are pointed outward

towards the two ends of each loading coil assembly as shown in Figure 5. .

NOTE: You can ease your tuning effort by pre-marking the outer ends of the spokes prior

to installation. You can do this by placing 1”, 2”, and 3” marks on one end of each

spoke using a black permanent marker pen. Then subdivide these marked

sections into ¼” segments using a red permanent marker pen.

NOTE: Install the spokes through the rings until they come in contact with the fiberglass

rod. This will give you about 1/4” of spoke available to slide back out should you

trim too much off a spoke during tuning.

12) Install four

short

spokes in the 20-meter rings of both loading coil assemblies. With a 5/16” nut

driver, tighten the nuts until the spokes are snug.

13) Install four

short

spokes in the 15-meter rings of both loading coil assemblies. With a 5/16” nut

driver, tighten the nuts until the spokes are snug.

14) Install four

short

spokes in the 10-eter rings of both loading coil assemblies. With a 5/16” nut driver,

tighten the nuts until the spokes are snug.

15) Install four

medium

(see note below)

spokes in the 40 meter rings of both loading coil assemblies.

With a 5/16” nut driver, tighten the nuts until the spokes are snug.

Note:

One or two of the 40 meter medium spokes on one loading coil only may need to be

replaced with long spokes, depending on the desired 40 meter operating frequency. See

the 40 meter tuning instructions below.

10 M

coil

15 M

coil

20 M

coil

40 M

coil

(4) 26”

spokes

(4) 12”

spokes

(4) 12”

spokes

(4) 12”

spokes

Figure 5: Loading Coil Assembly

AL tube fits

under this tab

Loosen to slide

AL tube under

the tab

Screw orientation