25

24.11.14 / V 01.0-E

Operation

18. Operation

Vor dem Arbeitsbeginn

Before starting the work

1. Check the material to be processed.

Can the material be milled

Check the drawing (bevel angle, size, processing )

2. Pay attention to a sufficient fixation of the material

For safety reasons,

To reduce vibration (improves the service life of the indexable inserts)

3. Prepare the machine

Select the required milling head off (bevel angle)

Mount it with the correct inserts (depending on material)

Adjust the first cutting height

4.

Pay attention to a proper working environment

Ensure that the work area is free of tripping hazards

Ensure that nobody is in the area of the chips flying

Ensure that no flammable objects are in the worksplace

5.

Wear your personal protective equipment

Glasses, work gloves, hearing protection, safety shoes and

a leather apron

Mit der HBM R3 arbeiten:

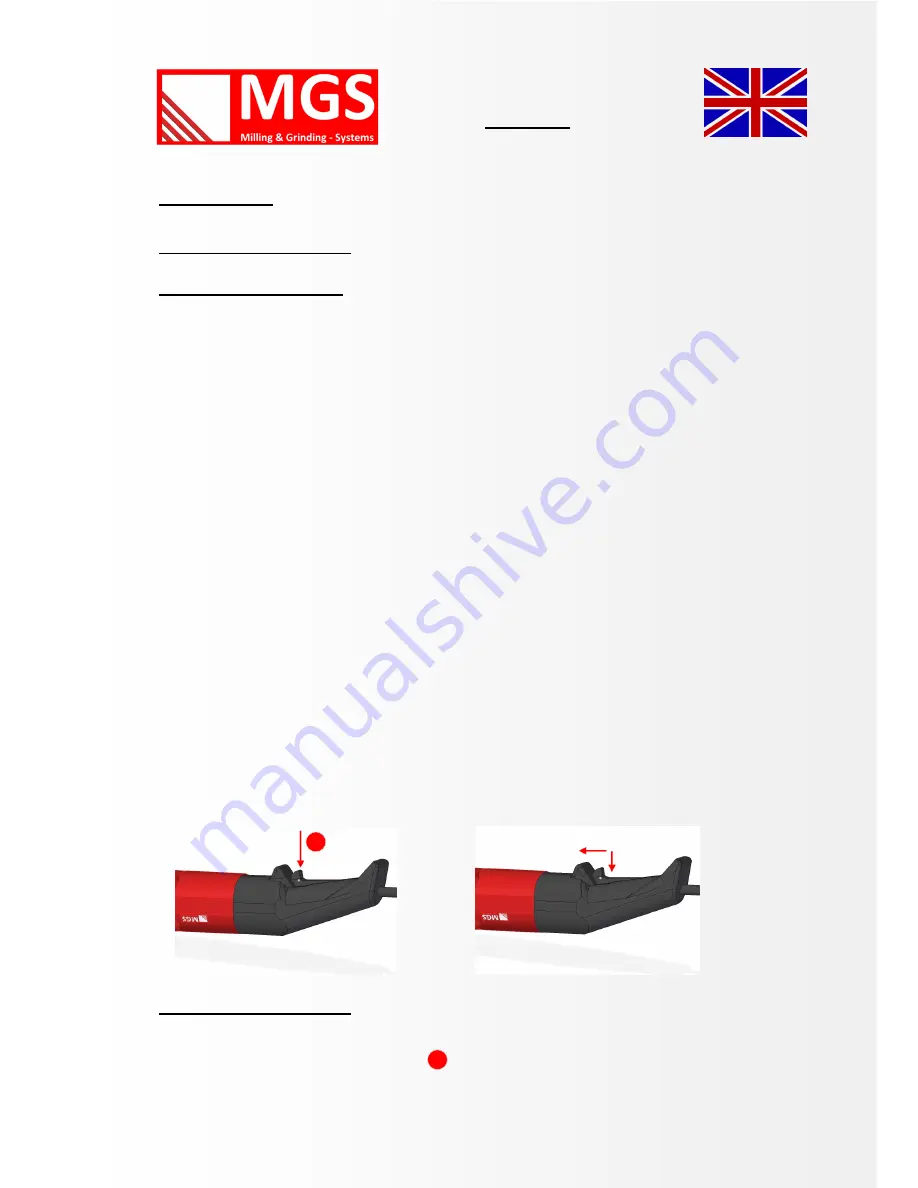

To exclude accidental starting edge milling machine HBM R3, the starter of the machine

is equipped with a locking startup.

7

7