© MHG Heating Ltd

2

MHG Heating Ltd Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey KT20 5LR

Telephone 08456 448802 Fax 08456 448803 Email

info@mhgheating.co.uk

Web www.mhgheating.co.uk

140116

Section

Page #

1.0

Appliance Type

3

1.1

ProCon H

3

1.2

ProCon S

3

1.3

ProCon HS

3

1.4

Supplied Components

3

2.0

Pressure Relief Valve

3

3.0

Installation Regulations and Requirements

4

3.1

Appliance Warranties. Supplied Components.

4

4.0

Dimensions

5

4.1

Installation Clearances

6

4.2

Mounting Information

7

5.0

Delivery and Mobility

7

5.1

Case Removal

7

6.0

Technical Data

8

7.0

Electrical Connections

9-10

7.1

I

nternal Wiring Diagram

11

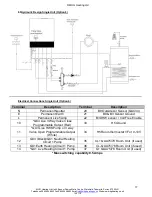

8.0

Hydraulic and Wiring Guide Single Unit Option 1 (Heating Only)

12

8.1

Hydraulic and Wiring Guide Single Unit Option 2 (Heating Only)

13

8.2

Hydraulic and Wiring Guide Single Unit Option 3 (Heating & HWS)

14

8.3

Hydraulic and Wiring Guide Single Unit Option 4 (Heating Only) ) (External 3 Way Valve)

15

8.4

Hydraulic and Wiring Guide Single Unit Option 5 (Heating & HWS) (Combi)

16

8.5

Hydraulic and Wiring Guide Single Unit Option 6 (Heating & HWS) ) (Internal 3 Way Valve)

17

8.6

Hydraulic and Wiring Guide Single Unit Option 7(Heating & HWS) (Two Heating Circuits)(HC2

External 3 Way Valve)

18

8.7

Hydraulic and Wiring Guide two boiler Cascade Option 8 (Heating & HWS) (Two Heating

Circuits)(HC2 External 3 Way Valve)

19

9.0

Fluing Options

20

9.1

Single Unit Balanced Flue Wall Termination

21

9.2

Single Unit Balanced Flue Vertical Termination

21

9.3

Single Unit Balanced Flue with Concentric to Twin DN80 Products of Combustion and

Combustion Air Ducts

.

21

9.4

Single Unit open Flue Wall Termination

22

9.5

Single Unit Open Flue Vertical Termination

22

9.6

Cascaded Open Flue Vertical Termination

22

9.7

Dimensions of Available Flue Components

23

9.8

Balanced Flue Terminal Positions For Boilers below and Above 70kW Net Input

24

10.0

Appliance Controls

25

10.1

Accessing Boiler Parameters (Control Parameter Default Settings)

26-60

10.2

Weather Compensation Slope Graph

61

10.3

Appliance Fault Codes Including Enhanced Fault Codes

61-63

11.0

Filling The System

64

11.1

Pressure Vessel

64

12.0

System Water Quality

65

12.1

Care With The Use Of Solder Flux

65

13.0

Commissioning

66

13.1

Pre-Commissioning Checks

66

13.2

Combustion System Commissioning

66

13.3

NG/LPG

– LPG/NG Conversion Procedure

67

14.0

Routine Inspection and Servicing

67

14.1

Routine Service Inspection Routine Cleaning and Maintenance

67-68

15.0

Exploded Spares Diagrams

69-72

Notes

73