03.

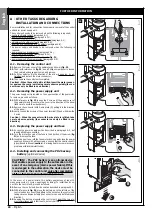

Fixing the gearmotor to the post (fig. 15).

a)

-

Place the gearmotor against the post (

*

) aligning its central vertical

axis with the vertical line previously traced on the post. Then align the

upper edge of the rear gearmotor bracket with the previously traced

horizontal line on the post (paragraph 3.4).

In this phase, ensure that the gearmotor is perfectly level; an offset

gearmotor could cause malfunctions of the automation.

(

*

)

Warning!

- If the post surface width is between 80 and 135 mm,

before proceeding with installation, the rear gearmotor fixing bracket

must be turned through 90°. Then follow the instructions in

fig. 21

.

b)

-

Mark the fixing points, drill the holes in the post and insert the plugs;

then secure the gearmotor using adequate screws and washers.

Note

- The screws are not included in the kit as their type depends

on the material and thickness of the post in which they are fixed.

c)

-

For increased stability of the gearmotor, adjust its rear feet so that

they are placed against the post. This adjustment can be made later,

when the control unit is removed from its seat for the first time (para-

graph 5.4).

04.

Shortening the length of the slotted arm (fig. 16).

a)

-

Loosen the nut of the slotted arm, remove the stop and move the two

pins apart, checking that the distance between them is the same as

the obtained

value C

. Then tighten the nut, but only provisionally.

05.

Checking that the length of the slotted arm is sufficient (fig. 17

and 18).

a)

-

Move the gate leaf to the maximum leaf closing position against the

travel limit stop.

b)

-

Extend the arm and move it up towards the leaf, placing the fixing

bracket on the arm. Then,

firmly press the curved arm against

the leaf (fig. 17-1a), until the two arms are completely

extended; apply force at the joining point (elbow fitting).

Caution! - the arms are completely extended only when the

elbow blocks against its stop.

c)

-

Ensure that the gearmotor arm is level (

fig. 17-1b

) and use a pencil to

mark

the centre

of the slots on the bracket (

fig. 17-2

), to enable sub-

sequent fine adjustments of leaf closure.

d)

-

Then provisionally fix the bracket on the leaf with a clamp or adhesive

tape and move the leaf to the maximum opening position, against the

floor-mounted travel stop.

e)

-

With the leaf in this position, check the gate as shown in

fig. 18-1

:

stretch a piece of string passing exactly above the two pins of the

slotted arm through to the leaf hinge pin. If the string is found

between the hinge pin and post in the area of the hinge pin (position

“BB” in

fig. 18-2

),

extend

the slotted arm by a few millimetres (value

“C”) and repeat the check. Repeat the procedure several times if nec-

essary until the string is located between the gate transit zone and

the leaf hinge pin (position “AA” in

fig. 18-2

), and until the arm no

longer comes into contact with the fixed obstacle behind the post.

06.

Cutting the slotted arm (fig. 19).

After ensuring correct operation of the entire arm, cut the excessive

part of the slotted arm as described below.

a)

-

Trace a line on the slotted arm in the exact position specified in phase

1 in

fig. 19.

Then remove the arm from the bracket and cut the

excess section of the arm.

b)

-

After removing any burrs found after cutting, re-assemble the arm

components with reference to

fig. 7

.

07.

Fixing the arm on the leaf (fig. 20).

a)

-

Drill the leaf at the marked points; remove the bracket from the arm

and fix it to the gate leaf with adequate screws.

Note

- The screws

are not included in the kit as their type depends on the material and

thickness of the post in which they are fixed.

b)

-

Fix the arm to the bracket, inserting the pin and stop benzing.

Impor-

tant

- Check that the bracket and arm are perfectly level. If neces-

sary, loosen the bracket screws and level as required.

c)

-

Permanently anchor the travel stops to the floor, in the same position

as established at the beginning of paragraph 3.4.

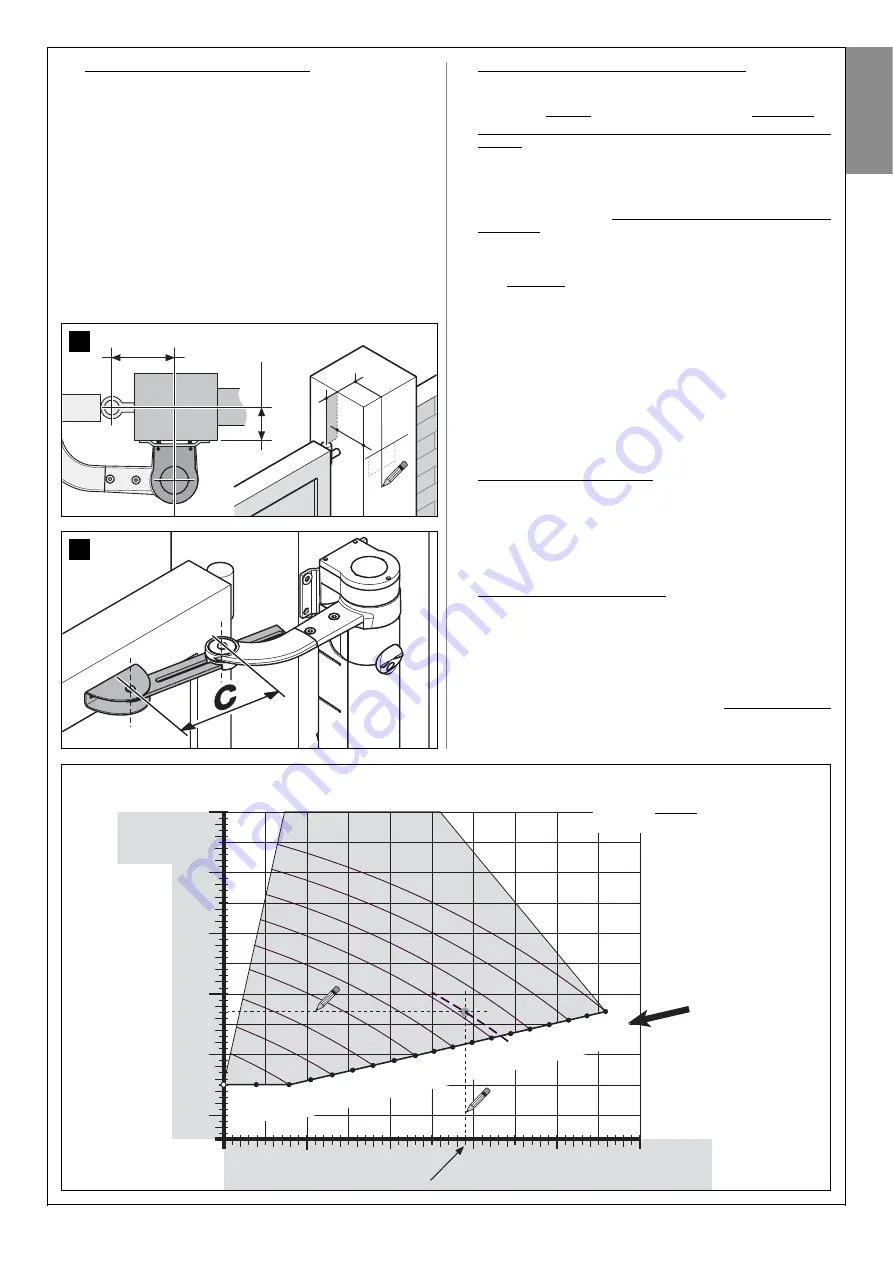

A

0

50

100

150

200

250

B

C

3

00

250

200

150

100

50

80

100

120

140

160

180

200

220

240

260

mm

B

= 145

GRAPH 4

(see paragraph 4.1B)

EXAMPLE:

if

value B

on the gate post

is measured at

145

mm and

value A

is

135 mm

value C

will be 210 mm

14

A

B

A

B

11

English

English –

11

Summary of Contents for WT1S

Page 11: ...1 2 3 4 45 3 1 2 a c b OK b a a b c d b a 5 6 7 8 9 10 11 12 13 13 English 10 English...

Page 14: ...OK b a 1 2 17 AA ok BB no OK 18 1 2 16 3 4 2 1 English English 13...

Page 15: ...b a 1 2 3 4 5 6 20 a b 1 2 3 4 19 English 14 English...

Page 36: ...Technical Documentation English English 35...

Page 37: ...English 36 English...

Page 39: ...English 38...

Page 41: ...English 40 English...

Page 44: ...Goniometer English English 43...

Page 45: ...44 English English Goniometer...