20

– English

English

CONTROL UNIT POWER SUPPLY AND PROGRAMMING

––– STEP 7 –––

STANDARD CONTROL UNIT PROGRAMMING

7.1 - LEARNING THE IDENTITY OF CONNECTED

DEVICES

After the initial checks described in Step 6 the control unit must learn the

identity of the devices connected to its terminals “ECSBus” and “STOP”.

The following procedure enables the control unit to recognise connected

devices one at a time, and to assign them with a specific unique address.

01.

On the control unit, press and hold P2 until Led P2 starts flashing

quickly; then release the key.

02.

Wait a few seconds for the control unit to learn all connected devices.

Learning is complete when the STOP Led remains lit and Led P2

turns off.

Caution!

– If Led P2 continues to flash this means that there

is an error; in this case read paragraph D - “Troubleshooting”.

Caution!

– In the future, if a new device is connected to the control unit

(for example, a new pair of photocells), or if a device is removed, this

learning procedure must be repeated.

––– STEP 6 –––

INITIAL START-UP AND

CONNECTION CHECK

6.1 - CONNECTING THE CONTROL UNIT TO THE POW-

ER MAINS

After installing and connecting all envisaged devices, insert the power

cable plug in a socket. In this phase, if the socket is far from the automa-

tion, an extension lead may be used.

IMPORTANT

– The cable supplied

is suitable for a provisional connection of the control unit to the mains, for

the purposes of programming and operation tests. When testing and

starting up the automation, the control unit must be connected perma-

nently to the electrical mains, creating a specific power line which also

includes a device to disconnect the automation from the power supply.

For these operations, read paragraph 8.1.

6.2 - IDENTIFYING KEYS AND LEDS ON THE CONTROL

UNIT

From the next paragraph onwards, the manual will deal with the keys, leds

and connectors present on the control unit. To identify them, refer to

fig.

27

, on the previous page.

6.3 - CHECKING ELECTRICAL CONNECTIONS AFTER

INITIAL POWER-UP

After powering up the control unit, the following checks should be per-

formed.

01.

On the control unit: check that the Led “ECSBus” flashes regularly (1

flash per second).

02.

On the two photocells (TX and RX): ensure that the Led “SAFE” (

fig.

28

) flashes (the type of flash is not important; it is simply important

whether the led is permanently lit or off.

03.

On the key-operated selector switch KS100 (if present): ensure that

the night-time lighting is lit.

If these checks do not obtain positive results, disconnect the control unit

from the power supply and check the cable connections. In these cases

refer also to paragraphs D and E (“Troubleshooting” and “Diagnostics and

Signals”) in the chapter “Further Details”.

CAUTION!

– All the subsequent operations de -

scribed in this manual will be made on live electric

circuits, and therefore manoeuvres may constitute

a hazard! Therefore take great care during these

operations.

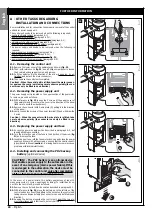

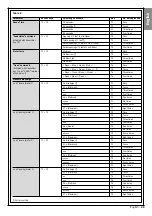

M2

M1

M2

M1

M1

M2

M1

M2

M2

M1

M1

M2

M2

M2

JA

JB

JA

JB

JA

JB

JA

JB

JA

JB

JA

JB

JA

JB

JA

JB

Overlapping leaf

motor with control unit

Overlapping leaf

motor with control unit

Overlapping leaf

motor with control unit

motor with control unit

motore con centrale

motor with control unit

motor with control unit

Overlapping leaf

motor with control unit

Table 3

Summary of Contents for WT1S

Page 11: ...1 2 3 4 45 3 1 2 a c b OK b a a b c d b a 5 6 7 8 9 10 11 12 13 13 English 10 English...

Page 14: ...OK b a 1 2 17 AA ok BB no OK 18 1 2 16 3 4 2 1 English English 13...

Page 15: ...b a 1 2 3 4 5 6 20 a b 1 2 3 4 19 English 14 English...

Page 36: ...Technical Documentation English English 35...

Page 37: ...English 36 English...

Page 39: ...English 38...

Page 41: ...English 40 English...

Page 44: ...Goniometer English English 43...

Page 45: ...44 English English Goniometer...