FURTHER INFORMATION

A - OTHER TASKS REGARDING

INSTALLATION AND CONNECTIONS

Some installation and/or connection tasks require removal of the control

unit and/or power supply unit.

The control unit needs to be removed when the following is required;

• control unit replacement (paragraph A.1);

• power cable replacement (paragraph 8.1.1);

• connection of PF photovoltaic power supply (paragraph A.5);

• adjustment of gearmotor feet (paragraph 5.4);

• insertion and connection of PR2 battery (paragraph A.4).

The power supply unit needs to be removed when the following is

required;

• power supply unit replacement (paragraph A.2);

• power cable replacement (paragraph 8.1.1);

• rotation of fixing bracket behind gearmotor (

fig. 21

);

• power supply unit fuse replacement (paragraph A.3).

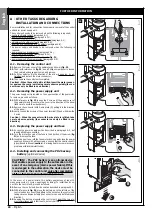

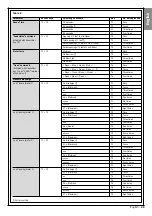

A.1 - Removing the control unit

01.

Remove the lower cover of the gearmotor as shown in

fig. 22

;

02.

Then, with reference to

fig. 32

, use a Phillips screwdriver to loosen

the 4 cable ducting support scres, and remove;

03.

Pull the control unit in the direction of the arrow, by approx. 4 cen-

timetres, and detach the motor connector;

04.

Then remove the control unit completely.

Caution!

- When the control unit is refitted, insert the motor connec-

tor again on the control unit, taking care to observe polarity (the con-

nector can only be fitted in one direction).

A.2 - Removing the power supply unit

The power supply unit is located on the upper section of the gearmotor.

To remove, proceed as follows.

01.

With reference to

fig. 33

, loosen the 3 screws of the upper cover of

the gearmotor and slowly turn the cover in the direction of the arrow

(take care to avoid the wires below!);

02.

Remove the connector with 5-wire plate (C), pulling it in the direction

of the arrow;

03.

Lastly, loosen the screws of the power terminal (D) and withdraw the

3 wires.

Caution!

- When the connector with 5-wire plate is refitted, take

care to observe polarity (the connector can only be fitted in one

direction).

A.3 - Replacing the power supply unit fuse

01.

Access the power supply unit as described in paragraph A.2, but

leaving all cables connected.

02.

Turn the protection cap of the fuse in the direction of the arrow (

fig.

3

4) and remove the fuse.

03.

Insert the new fuse, refit the fuse protection cap and close the power

supply unit cover with all the screws, ensuring that the seal is correct-

ly positioned in its seat (

caution

! - A missing seal or screw may cause

problems with internal electronics).

A.4 - Installing and connecting the PR2 backup

battery

(optional device)

In the event of a power failure, this battery guarantees at least 10

manoeuvre cycles (1 cycle = opening and closing). To install it and con-

nect it to the control unit, proceed as follows.

01.

Remove the control unit from its seat as described in paragraph A.1.

02.

With reference to

fig. 35

, move the battery up to the left side of the

control unit and connect the battery to the socket on the control unit,

taking care to observe polarity (the connector can only be fitted in one

direction).

03.

Keeping the battery alongside the control unit, insert the two ele-

ments simultaneously in their seats, but only half way.

CAUTION!

- The PR2 battery is an optional device

that enables power supply to the automation in the

event of an emergency (mains power failure). If this

is envisaged in the automation, the device must be

connected to the control unit only after completing

all the other tasks described in this manual.

A

B

C

2

1

4

3

32

English

24

– English

Summary of Contents for WT1S

Page 11: ...1 2 3 4 45 3 1 2 a c b OK b a a b c d b a 5 6 7 8 9 10 11 12 13 13 English 10 English...

Page 14: ...OK b a 1 2 17 AA ok BB no OK 18 1 2 16 3 4 2 1 English English 13...

Page 15: ...b a 1 2 3 4 5 6 20 a b 1 2 3 4 19 English 14 English...

Page 36: ...Technical Documentation English English 35...

Page 37: ...English 36 English...

Page 39: ...English 38...

Page 41: ...English 40 English...

Page 44: ...Goniometer English English 43...

Page 45: ...44 English English Goniometer...