02.

On the graphs (North or South) supplied in the PF kit instruction man-

ual, locate the curve for the location’s

latitude

(

e.g: 45°N)

.

03.

Choose the

period of the year

on which to base the calculation, or

select the lowest point of the curve to calculate

the worst period of

the year;

then read the corresponding value

Am

(e.g. December,

January: Am= 200)

.

04.

Calculate the value of energy available

Ed

(produced by the panel)

multiplying

Ea

x

Am

=

Ed

(example: Ea = 14; Am = 200, i.e. Ed =

2800)

.

• Calculating the energy consumed

To calculate the energy consumed by the automation, proceed as follows:

05.

On the table below, select the box corresponding to the intersection

between the line with the

weight

and the column with the

opening

angle

of the leaf. The box contains the value of the

severity index

(K)

for each manoeuvre

(

e.g.

gearmotor with standard arm on leaf of 130

Kg and 95° opening; K = 84)

.

06.

On the

table 4,

select the box corresponding to the intersection

between the line with the

Ed

value and the column with the

K

value.

The box contains the maximum possible number of cycles per day

(e.g.

Ed= 2800; K= 84; cycles per day = 30)

.

If the number obtained is too low for the envisaged use or is located in the

“area not recommended for use”, the use of 2 or more photovoltaic pan-

els may be considered, or the use of a photovoltaic panel with a higher

power. Contact the Mhouse technical assistance service for further infor-

mation.

The method described enables the calculation of the maximum possible

number of cycles

per day

that can be completed by the automation while

running on solar power. The calculated value is considered an average

value and the same for all days of the week. Considering the presence of

the battery, which acts as an energy “storage depot”, and the fact that the

battery enables automation autonomy also for long periods of bad weath-

er (when the photovoltaic panel produces very little energy) it may be pos-

sible to exceed the calculated maximum possible number of cycles per

day, provided that the average of 10-15 days remains within the envis-

aged limits.

Table 5

specifies the maximum possible number of cycles, according to

the manoeuvre’s

severity index

(K), using

exclusively the energy stored

by the battery. It is considered that initially the battery is completely

charged (e.g. after a prolonged period of good weather or recharging via

the optional PCB power supply unit) and that the manoeuvres are per-

formed within a period of 30 days.

When the battery runs out of the stored energy, the led starts to indicate

the battery low signal by flashing briefly every 5 seconds, accompanied by

a “beep”.

If the “WT” is used on a single leaf gate (with only one gearmotor), the

maximum possible number of cycles corresponds to the value in the

tables, multiplied by

1.5.

For example, if the calculated number of cycles

is 30 and the gate has one leaf only, the number of cycles will be: 30 x

1,5

= 45.

A.6 - “Stand-by” function when the device PR2

and/or PF is installed

(optional devices)

When the automation is powered by the backup battery PR2 or the pho-

tovoltaic system PF, the “standby” function is activated automatically 60

seconds after completion of an automatic manoeuvre cycle. This turns off

the “ECSbus” output and all connected devices, the outputs “Flash”, “Els”

and all leds, with the exception of the ECSbus led which flashes more

slowly (1 flash every 5 seconds). After this, as soon as the user sends a

command, the control unit restores power and starts the manoeuvre

(this

may start with a short delay).

A.7 - Using the “ECSBus” input/output

Only devices compatible with ESCBus technology must be connected to

the terminal “ESCBus” (this is explained in detail in paragraph 3.3.3).

Important

– Following testing of the automation, each time new

devices are connected to (or removed from) the “ECSBus” terminal,

the learning procedure must be performed as described in para-

graph A.10.

A.8 - Using the “STOP” input

STOP is the input that causes immediate shutdown of the manoeuvre

(with brief inversion). This input can be connected to devices with contact

types Normally Open (NO, as in the case of the KS100 selector switch),

Normally Closed (NC) or devices with a constant resistance of 8.2 K

Ω

,

such as sensitive edges.

When set accordingly, more than one device can be connected to the

STOP input, also different from one another. For this function, refer to

Table 6

and the following notes to the table.

Note 1.

The combination NO and NC is possible by connecting the 2

contacts in parallel, taking care to connect a 8.2k

Ω

resistance to

the NC contact (this enabling the combination of 3 devices: NO,

NC and 8,2k

Ω

).

Note 2.

Any number of NO devices can be connected to each other in

parallel.

Note 3.

Any number of NC devices can be connected to each other in

series.

Note 4.

Two devices with a 8,2k

Ω

constant resistance can be connected

in parallel. However if there are more than two of these devices,

they must be connected “in cascade” placing only one terminat-

ing resistance of 8,2k

Ω

.

Warning!

– If devices with safety functions are connected to the “STOP”

input, only devices with a constant 8,2k

Ω

resistance output can guaran-

tee fault safety category 3.

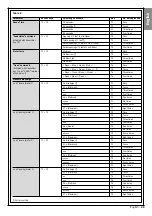

TABLE 4 - Maximum number of cycles per day

(see paragraph A.5.1)

Ed

K

≤

50

K

≤

75

K=100

K=125

K=150

K=175

K=200

K=225

K=250

K=275

K=300

9500

183

122

92

73

61

52

46

41

37

33

31

9000

173

115

87

69

58

49

43

38

35

31

29

8500

163

109

82

65

54

47

41

36

33

30

27

8000

153

102

77

61

51

44

38

34

31

28

2

7500

143

95

72

57

48

41

36

32

29

26

24

7000

133

89

67

53

44

38

33

30

27

24

22

6500

123

82

62

49

41

35

31

27

25

22

21

6000

113

75

57

45

38

32

28

25

23

21

19

5500

103

69

52

41

34

29

26

23

21

19

17

5000

93

62

47

37

31

27

23

21

19

17

16

4500

83

55

42

33

28

24

21

18

17

15

14

4000

73

49

37

29

24

21

18

16

15

13

12

3500

63

42

32

25

21

18

16

14

13

11

11

3000

53

35

27

21

18

15

13

12

11

10

9

2500

43

29

22

17

14

12

11

10

9

8

7

2000

33

22

17

13

11

9

8

7

7

6

6

1500

23

15

12

9

8

7

6

1000

13

9

7

Area of use not recommended

TABLE 5 - Maximum number of cycles using exclusively battery power

(see paragraph A.5.1)

K

≤

50

K

≤

75

K=100

K=125

K=150

K=175

K=200

K=225

K=250

K=275

K=300

1082

721

541

433

361

309

271

240

216

197

180

Opening angle

with standard arm with short arm

Leaf weight

≤

90°

90÷100° 100÷110°

≤

90°

90÷100° 100÷110°

< 80 Kg

30

44

60

60

84

112

80-120 Kg

42

58

90

90

128

200

120-150 Kg

55

84

144

144

220

288

150-180 Kg

86

126

220

motor

English

26

– English

Summary of Contents for WT1S

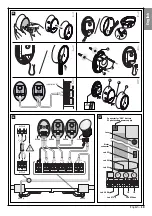

Page 11: ...1 2 3 4 45 3 1 2 a c b OK b a a b c d b a 5 6 7 8 9 10 11 12 13 13 English 10 English...

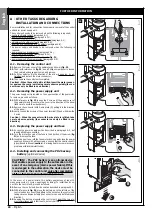

Page 14: ...OK b a 1 2 17 AA ok BB no OK 18 1 2 16 3 4 2 1 English English 13...

Page 15: ...b a 1 2 3 4 5 6 20 a b 1 2 3 4 19 English 14 English...

Page 36: ...Technical Documentation English English 35...

Page 37: ...English 36 English...

Page 39: ...English 38...

Page 41: ...English 40 English...

Page 44: ...Goniometer English English 43...

Page 45: ...44 English English Goniometer...