––– STEP 3 –––

CHECKS AND PROCEDURES PRIOR

TO INSTALLATION

3.1 - CHECKING SUITABILITY OF GATE TO BE AUTO-

MATED AND RELATIVE ENVIRONMENT

• Ensure that the mechanical structure of the gate complies with current

national standards and that it is suitable for automation. For this check,

refer to the information specified on the gate dataplate.

Important

-

This “WT” system cannot be used to automate a gate that is not already

efficient and safe; furthermore it cannot solve defects caused by incor-

rect gate installation or poor maintenance.

• Ensure that the gate leafs move regularly and smoothly, by performing

the following test: manually move the leafs in both directions and ensure

that movement is free of friction throughout all points of travel (there

must be no points requiring a different level of force).

• Ensure that the gate leafs are perfectly balanced, by performing the fol-

lowing test: manually move the leafs to any position; take away the

hands and ensure that the leafs remain stationary.

• If there is a fixed obstacle in the zone of the column (where the gearmo-

tor is to be installed) it is important to check whether this will enable

complete arm rotation and therefore the maximum leaf opening angle.

For this check, refer to point 5 of paragraph 3.2.

• In the vicinity of the post where the gearmotor is to be installed, ensure

that there is sufficient space to perform the manual gearmotor release

procedure.

• Ensure that the surfaces chosen for device installation are solid and can

guarantee a stable fixture.

• Ensure that all devices to be installed are in a sheltered location and

protected against the risk of accidental impact.

• Ensure that the area is fitted with floor-mounted stops (not supplied), to

limit opening and closing.

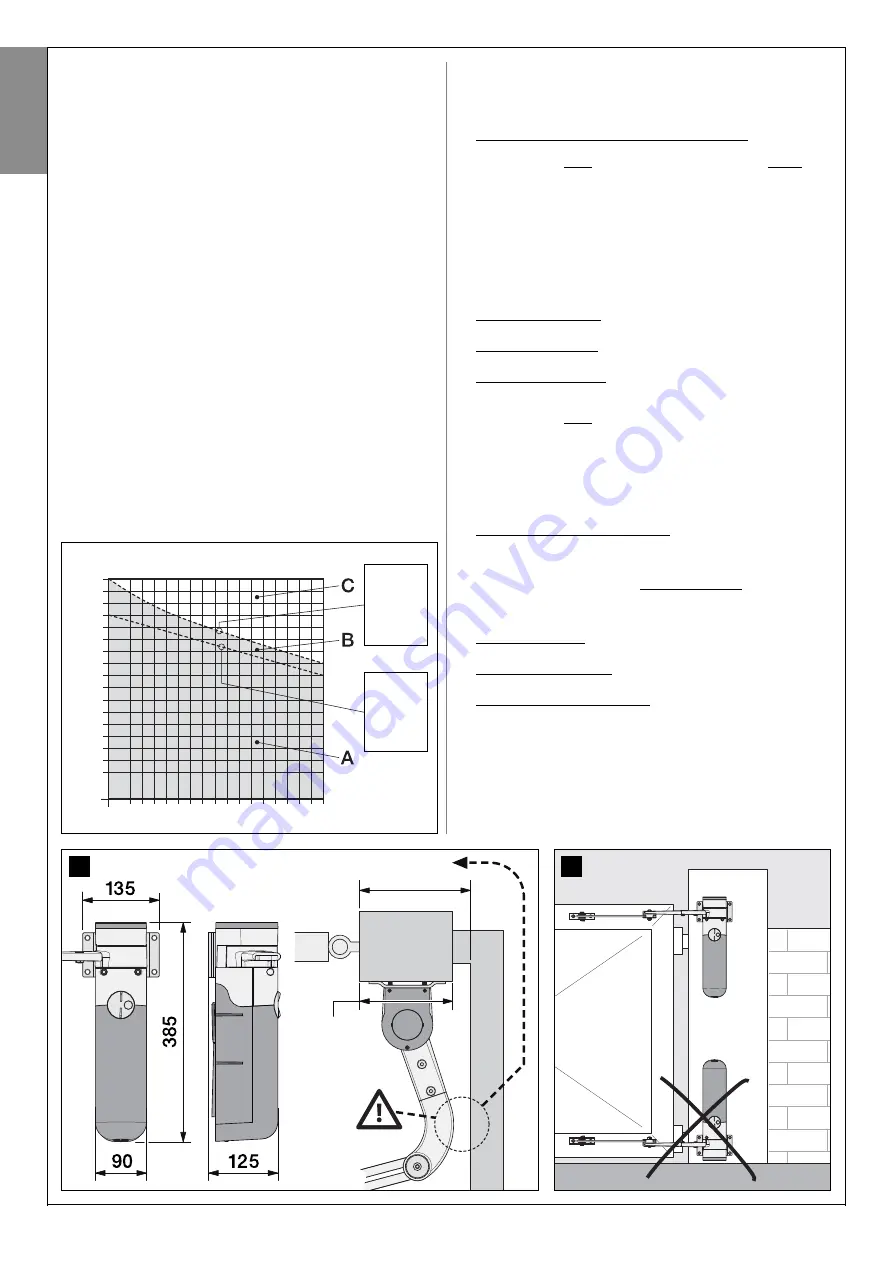

3.2 - CHECKING THE PRODUCT APPLICATION LIMITS

1 - Suitability of the product for gate automation

. For this check,

refer to

Graph 1

as follows:

a)

- measure the width of the gate leaf and determine its weight.

b)

- note these two values in

Graph 1

and check the point at which

the two values intersect:

•

if the point is located within area “A”

= the gate can be automat-

ed using standard length arms (supplied as standard) or short arms

(the length of the arm is established during the phase prior to installa-

tion - paragraph 3.4);

•

if the point is located within area “B”

= the gate can be automat-

ed using standard length arms (supplied as standard);

•

if the point is located within area “C”

= this product cannot be

used to automate the gate.

2 - Maximum leaf height

. The “WT” system can automate leafs with a

height of up to 200 cm.

3 - Maximum leaf width

. The “WT” system can automate leafs with a

width of up to 160 cm (see

Graph 1

).

4 - Maximum leaf weight

. The maximum weight of the leaf depends

on its length. To calculate the maximum admissible weight with the

“WT” system, proceed as follows:

a)

- measure the width of the gate leaf and note the value in

Graph 1

.

Starting from this value, trace a vertical line until it intersects with the

two traced lines.

b)

- trace a horizontal line from each point of intersection, until the two

maximum admissible weights are shown (depending on the length of

the arm used to install the gearmotor: with standard length arms, the

weight may vary from 110 to 180 Kg; with short arms, the weight may

vary from 100 to 150 Kg).

5 - Gearmotor overall dimensions

. On the basis of the overall

dimensions stated in

fig. 2

, check that there is sufficient space on the

leaf and post to enable gearmotor installation. In particular, ensure the

following:

• the width of the post must be greater than 80 mm (

fig. 2

).

Caution!

– any lower widths would prevent installation of the gearmotor.

• the distance between the edge of the post (the side closest to the

hinge pin) and any fixed obstacle present behind the post, must be

greater than 120 mm (

fig. 2

).

Caution!

– any lower widths would pre-

vent installation of the gearmotor.

6 - Gearmotor positioning

. Never install the gearmotor upside down

(see

fig. 3

).

7 - Maximum leaf opening angle

. If the gearmotor is installed with a

standard length arm (supplied as standard) a leaf opening angle of

110° is possible. Otherwise, if the short arm is used, the leaf opening

angle is reduced to 90°. The length of the arm is established during

the phase prior to installation - see paragraph 3.4.

2

3

180

160

140

120

100

80

60

40

20

0,8

0

1

1,2

1,4

1,6

0,9

1,1

1,5

1,3

GRAPH 1

(see paragraph 3.2)

WIDTH (m)

WEIGHT (kg)

line of

maximum

leaf weight:

with stan-

dard arm

line of

maximum

leaf weight:

with short

arm

80 mm

minimum

120 mm

minimum

YES

NO

English

4

– English

Summary of Contents for WT1S

Page 11: ...1 2 3 4 45 3 1 2 a c b OK b a a b c d b a 5 6 7 8 9 10 11 12 13 13 English 10 English...

Page 14: ...OK b a 1 2 17 AA ok BB no OK 18 1 2 16 3 4 2 1 English English 13...

Page 15: ...b a 1 2 3 4 5 6 20 a b 1 2 3 4 19 English 14 English...

Page 36: ...Technical Documentation English English 35...

Page 37: ...English 36 English...

Page 39: ...English 38...

Page 41: ...English 40 English...

Page 44: ...Goniometer English English 43...

Page 45: ...44 English English Goniometer...