TABLE 1

- Severity index

(see paragraph 3.2-9)

8 - Mechanical stops

. The gearmotors in the “WT” system do not

implement mechanical systems to limit leaf travel on closing or open-

ing. Therefore, to enable installation of the “WT” system, some floor-

mounted stops on opening and closing must be fitted

(these stops

are not supplied in the kit and are not part of the Mhouse product

range)

.

9 - Product durability

. The lifetime is the average economic duration

of the product. The value of lifetime is strongly influenced by the inten-

sity of the manoeuvres, i.e. the sum of all factors that contribute to

product wear; these values are shown in

Table 1

and we therefore

recommend making an estimate of the automation lifetime after com-

missioning, using the following calculation:

01.

In

Table 1

, locate the values “Leaf length” and “Leaf weight” of

your gate and note the corresponding “Severity index”, taking care to

check the length of the arm on which the gearmotor is installed. In the

specific context, if there are other factors that influence stress of the

manoeuvre, locate the relative values in Table 1 and add them to the

sum obtained beforehand.

Example

: • “Leaf length” = 1,5 m; “leaf weight” = 92 Kg; “arm length”

= standard; therefore,

severity index = 55%

.

Presence of factors influencing stress on the manoeuvres: • “ambient

temperature...” = No; “solid leaf” = Yes; “arm length” = standard;

therefore,

severity index = 15%

; “Installation in windy zone” = Yes;

“arm length” = standard; therefore,

severity index = 15%

. •

TOTAL

INDEX: 55% + 15% + 15% = 85%

.

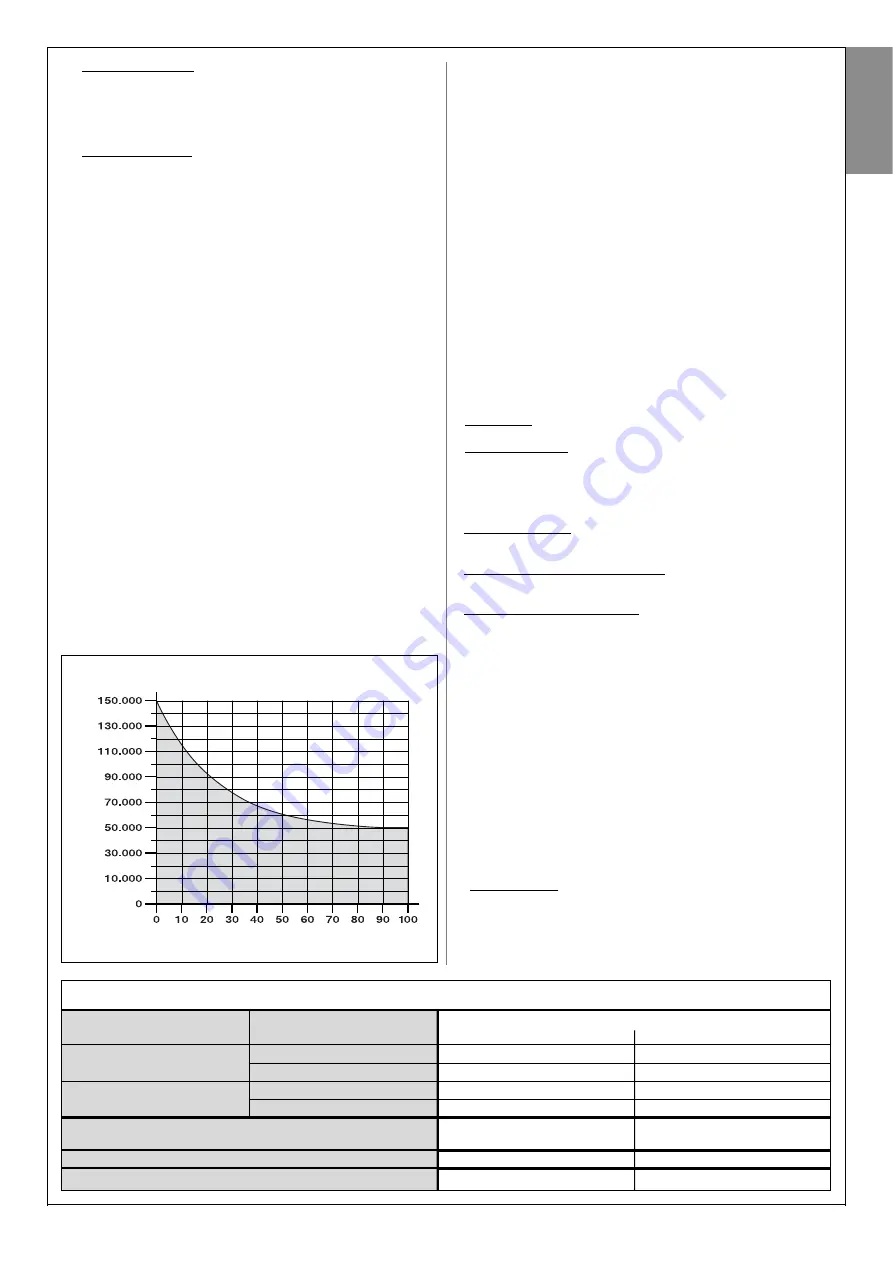

02.

In

Graph 2

, note the total value of severity obtained (in the exam-

ple = 85%) and trace a vertical line from this point, until it intersects

the curve in the graph. Then, from the point of intersection, trace a

horizontal line through to the vertical axis of the graph. The value

obtained (number of manoeuvre cycles) represents the estimated

durability of the product.

Example

: total severity index = 85%. In Graph 1, this corresponds to

approximately 51,000 manoeuvre cycles (= product durability).

The lifetime values specified in the graph are only obtainable if the

maintenance schedule is strictly observed (see paragraph 10.1). The

estimation of lifetime is made on the basis of design calculations and

the results of tests performed on prototypes. As it is only an estima-

tion, it does not represent any form of guarantee on the effective life-

time of the product.

3.3 - PRELIMINARY CHECKS FOR INSTALLATION

3.3.1 - Ensure all equipment and materials for work are available

Before starting work, ensure that you have all equipment and materials

required to complete the work. Ensure that all items are in good condition

and comply with local safety standards.

3.3.2 - Establish the position of devices in the system

To establish the installation position of each device envisaged in the sys-

tem, refer to

fig. 4.

This illustrates a system set up using the components

supplied in the kit as well as other optional devices and accessories. The

figure shows an ideal layout of the devices. The devices used are:

a

- Electromechanical gearmotor with control unit WT1SC

b

- Electromechanical gearmotor without control unit WT1SK

c

- Pair of photocells PH100 (wall-mounted)

d

- Flashing light FL100

e

- Key-operated selector switch KS100 (wall-mounted)

f

- Pair of posts for PT50 photocells PT50 (h = 50 cm) / PT100 (h = 100

cm)

g

- Opening travel limit stops

(these are not part of the Mhouse product

range; they may also constitute “natural” obstacles, such as a wall,

edge of a flower bed etc.)

h

- Closing travel limit stop

(this is not part of the Mhouse product range)

When selecting the position of each device, take special care to observe

the following:

• Gearmotors

– the gearmotor with control unit must be positioned on

the leaf closest to the zone where the power supply is located.

• PH100 photocells

– the two photocells (TX and RX) must be posi-

tioned:

a

) at a height of 40-60 cm from the ground;

b

) to the sides of the

zone to be protected;

c

) outside the gate, i.e. on the side of the public

road;

d

) trim with the gate (max. 15 cm from the latter);

e

) the TX photocell

(transmitting) must be directed at the RX photocell (receiving), with a max-

imum tolerance of 5°.

• FL100 flashing light

– this must be positioned in the vicinity of the gate;

it must also be easily visible from any point of access to the gate.

Note

–

the device can be fixed to a horizontal or vertical surface.

• KS100 key-operated selector switch

– this must be positioned to the

side of the gate and must be installed at a height of approx. 80 cm, so

that it can also be used by persons of different heights.

• Other fixed type control devices

– these must be positioned in view of

the automation, far from all moving parts at a minimum height of 1.5 m

from the ground; they must also not be accessible by unauthorised per-

sons.

3.3.3 - Setting the route of the connection cables

To establish the route of each connection cable and thus dig the race-

ways for the cable ducting, the following constraints must be taken into

account:

a

)

points envisaged for device installation

(read paragraph 3.3.2);

b

)

the envisaged connection between all devices and terminals

involved

(see

fig. 26

);

c

)

“ECSBus” technology

. This technology enables the connection and

communication between several devices (including the control unit by

means of the ECSBus terminal) with a single cable containing 2 elec-

trical wires (carrying the electric power and data communication sig-

nals). This cable can only be used to connect Mhouse devices com-

patible with the ECSBus protocol: for example the photocells, safety

devices, control buttons, indicator lights etc. (for information on com-

patible devices, refer to the Mhouse catalogue or visit the website

www.mhouse.biz). “ECSBus” technology offers the possibility of using

different layouts for device connections. Some examples are shown in

fig. 5

.

Severity index

STANDARD arm length

SHORT arm length

< 1,2 m

1,2 - 1,6 m

1a

- Leaf length

1b

- Leaf weight

2

- Ambient temperature: over 40°C or lower than 0°C or humidity

greater than 80%

3

- Solid leaf

4

- Installation in windy zone

> 100 kg

< 100 kg

> 80 kg

< 80 kg

55%

30%

55%

40%

65%

50%

65%

50%

15%

15%

15%

15%

10%

10%

GRAPH 2

(see paragraph 3.2 - 9)

manoeuvr

e cycles

severity index (%)

English

English –

5

Summary of Contents for WT1S

Page 11: ...1 2 3 4 45 3 1 2 a c b OK b a a b c d b a 5 6 7 8 9 10 11 12 13 13 English 10 English...

Page 14: ...OK b a 1 2 17 AA ok BB no OK 18 1 2 16 3 4 2 1 English English 13...

Page 15: ...b a 1 2 3 4 5 6 20 a b 1 2 3 4 19 English 14 English...

Page 36: ...Technical Documentation English English 35...

Page 37: ...English 36 English...

Page 39: ...English 38...

Page 41: ...English 40 English...

Page 44: ...Goniometer English English 43...

Page 45: ...44 English English Goniometer...