SAFETY PRECAUTIONS

1. You as the owner of this Sand Injector are responsible for

the safety of the operator. Read and understand this manual.

Provide a copy to the operator as standard procedure.

2. Before attempting to install this injector, make sure the machine

is shut off and the pressure in the system is released (by

triggering the gun momentarily).

3. Protective goggles are supplied with this sand injector.

4. Always wear eye protection when using a pressure washer. Other protective clothing. i.e. rubber suits, rubber gloves,

respirator, etc. may be necessary. Read sand label for recommended precautions.

5. When using the injector with a pressure washer, the operator must be provided with an operator's manual for that

model and become acquainted with all the safety, installation and operational procedures provided therein.

OPERATION INSTRUCTIONS

Place the sand induction probe in the sand supply container.

Connect the mixing head to the spray wand. Start the machine per manufacturer’s instruction.

Trigger the gun to activate the spray.

Check the distance to hold the spray nozzle from the surface by starting to spray at a scrap of material from a distance of

several feet. Gradually move closer, checking frequently to see if the high pressure spray is damaging the surface.

Refer to the application table for the type of sand recommended for your work surface.

Always point the sand nozzle downward when not spraying. This will prevent water from entering the sand supply. If water

does get into the sand supply hose, remove the probe from the sand, hold control handle trigger open, and let the hose air

dry. Always be sure the sand hose is dry before using.

Keep the sand covered to prevent the overspray from wetting the sand. Do not allow small fragments of the sand bag to fall

into the sand supply. A small paper fragment could prevent the flow of sand.

After the sandblasting operation is complete, remove the probe from the sand, trigger the gun to clear the hose and probe

of sand. Then remove the hose from the mixing head and rinse with water to remove all the sand before storage.

APPLICATIONS

Sand Mesh: Sand mesh refers to the size of screen through which a particular grade of sand will pass. A 16/50 mesh means

that normally, most of the particles will pass through a

#16 screen and a very small percentage will pass through

a #50 screen.

Note: A #16 screen has 16 0.046 holes per square inch.

Round Sand: This refers to the round edge of the grain

of sand. River sand is a good example of sand worn to

its shape by water.

Angular Sand: This refers to grains of sand which have

triangular shaped edges. Crushed rock or sand is usually

of this type.

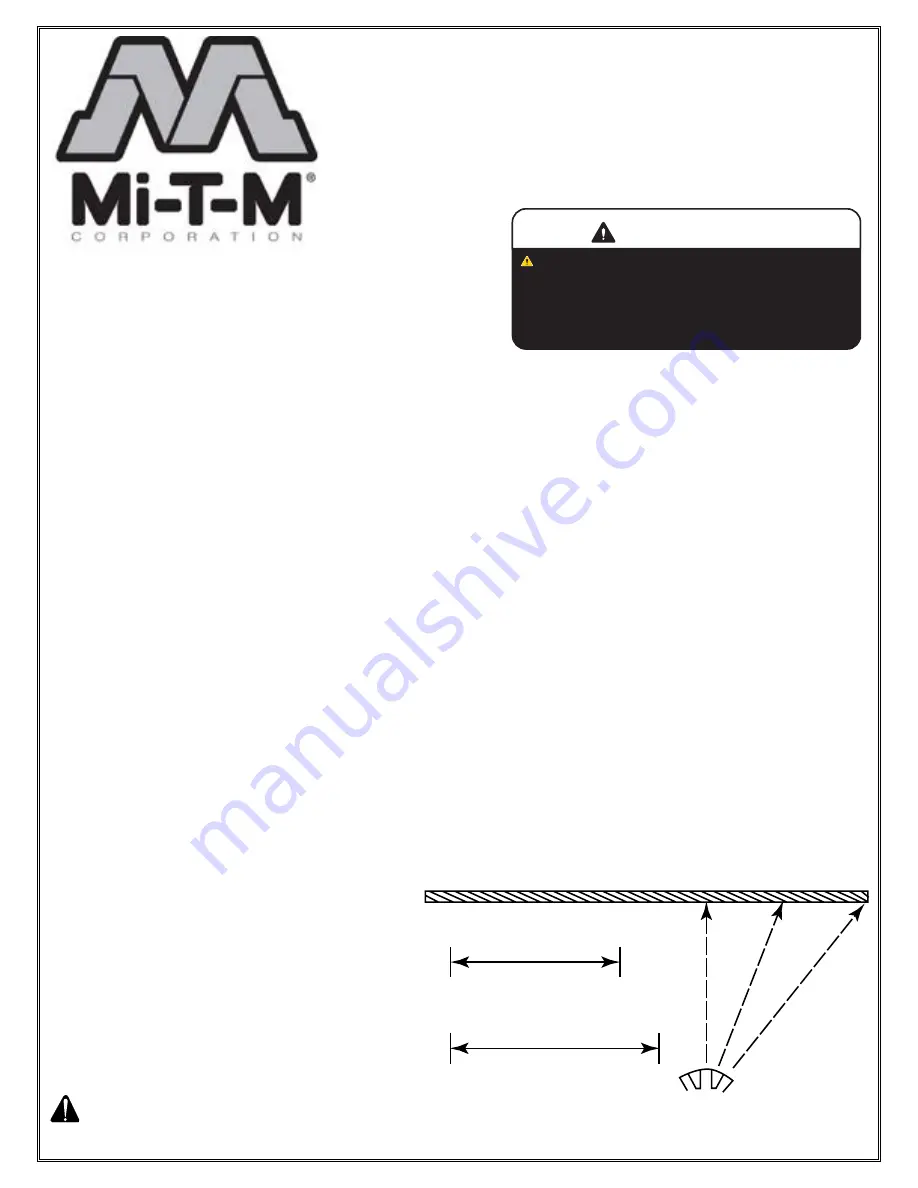

Blasting Angle and Distance: The blasting angle can

affect the sandblasting distance. For the best sandblasting

performance always maintain the recommended blasting

angle and the proper distance for your work surface.

CAUTION: RISK OF INJURY! READ ENTIRE

MANUAL BEFORE OPERATING! THIS

MANUAL IS AN IMPORTANT PART OF THE SAND INJECTOR AND MUST REMAIN WITH THIS UNIT!

SAND INJECTOR

AW-3000-0000

©Copyright 2005, Mi-T-M Corporation

37-0018-072318

Manufactured by Mi-T-M

50 Mi-T-M Drive, Peosta IA 52068

563-556-7484/ Fax 563-556-1235

Blasting Angle and Distance Chart

Sandblasting Distance at 0°

Sandblasting Distance at 30°

0°

15°

30

°

Nozzle

WARNING: This product can expose you to

chemicals including Lead, which is known to

the State of California to cause cancer and birth

defects or other reproductive harm. For more

information go to www.P65Warnings.ca.gov

WARNING