2

3

13

6

5

11

10

4

9

8

7

12

14

15

16

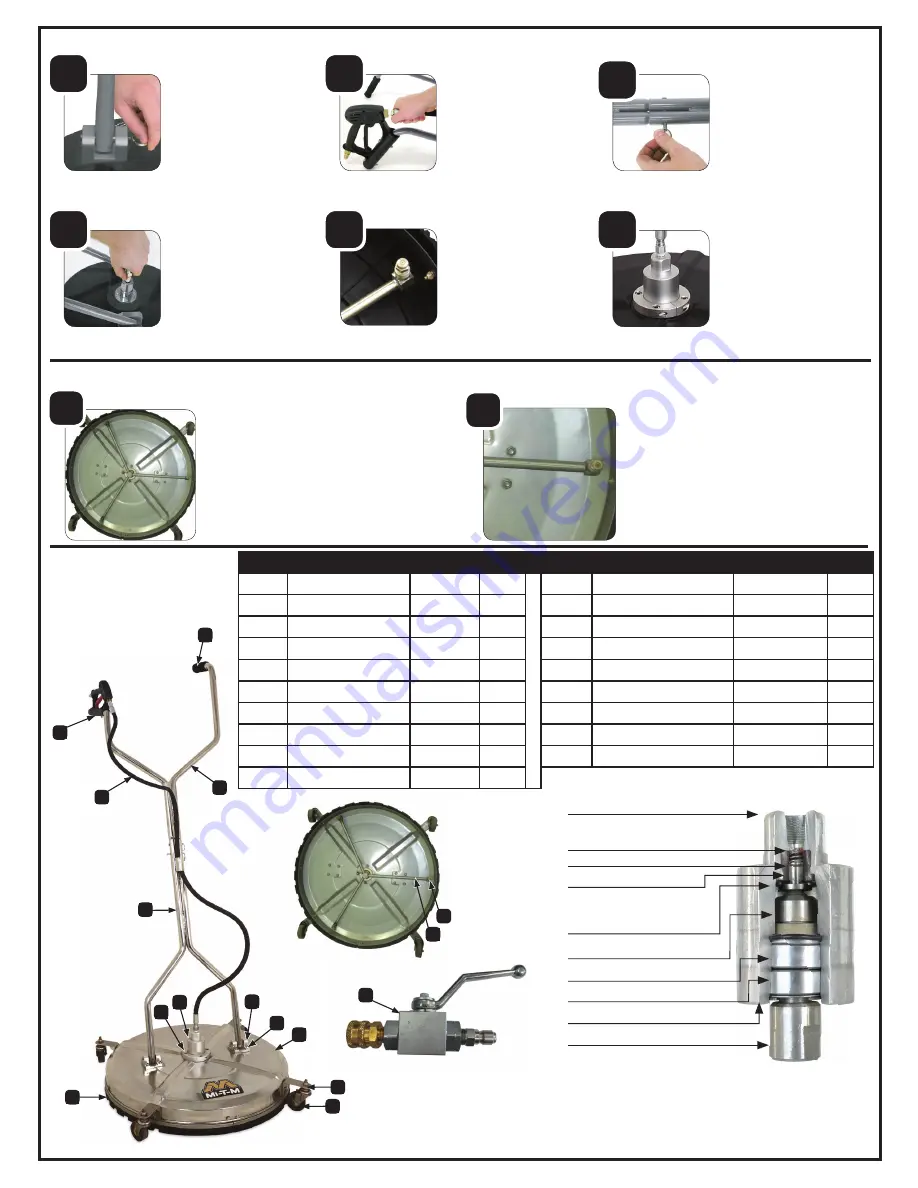

AW-7020-8007

Ref. # Description

Part #

Qty.

Ref. # Description

Part #

Qty.

1

Ball Valve Kit

50-0210

1

10

Cover

33-0552

1

2

Spray Gun

16-0465

1

11

Mounting Blocks

56-0072

2

3

Hose, 62” x 3/8”

15-0326

1

12

Pin and Ring Set

43-0140

1

4

Handle, Lower

7-0244

1

13

Handle, Upper

7-0243

1

5

Rotary Head*

33-0535

1

14

Hand Grip

7-0237

1

6

Collar

33-0534

1

15

Rotary Arm

33-0553

1

7

Nylon Brush

33-0551

1

16

Nozzle, 25 Deg. 020

18-0298

3

8

Caster

14-0135

4

*

Head Rebuild Kit

70-0598

1

9

Caster Bracket

13-0228

4

SET UP PROCEDURES

TROUBLE SHOOTING

PARTS LIST

1

2

3

We recommend that

you first fit the lower

portion of the han-

dle into the mounting

brackets on the cover

and secure with the

bolts or the pins & clips.

Next, tighten the

“fixed” hose end into

the gun mounted onto

the upper portion of the

handle. Use teflon tape

on the hose ends and

tighten with a wrench

until snug. Do not

overtighten.

Once this is complete,

join the two sections of

the handle together and

secure with the bolt or

the pin & clip.

4

5

6

Next, tighten the swivel

end of the hose with a

wrench into the top of

the rotary head until

snug.

Turn the cover over

and check to ensure

that the nozzle tips are

securely tightened and

the spray pattern is in

line with the rotary arm.

The factory presets the

height of your rotary

head from the ground

based on peak perfor-

mance. If you choose to

lower or raise the height

of the head, loosen the

tension bolt in the collar.

1

2

Rotary Arm doesn’t spin:

• Remove, inspect and clean nozzles.

Replace if damaged

• Ensure there is no water leaking

excessively from the weep holes on

the rotary head (water will normally

seep out of these holes).

Leaves striping:

• Ensure nozzles aren’t damaged or

plugged.

• Ensure rotary arms are straight.

• Ensure nozzle groove is in align-

ment with arm.

** Note that lowering the head too far may result in the rotary arm hitting the surface and damaging it.

1

WARRANTY

The rotary head has a six-month warranty from the date of purchase. Should you

encounter problems with the rotary head within that time period, simply return the

defective part for warranty to the place of purchase.

There is no warranty on the nylon brush ring. All other components of the surface

cleaning system have a 90-day warranty against manufacturer’s defects only.

Hose connection inlet

Stainless steel inlet valve

with Carbide seat (22-0488

includes oring)

Stainless steel bearings

Stainless steel rotating shaft

Aluminum housing

Stainless steel spring

Viton O-Ring (25-0679)

Viton O-Ring (25-0677)

WHIRL-A-WAY ROTARY HEAD BREAKDOWN

Stainless steel sleeve

Viton O-Ring (25-0678)