12

Work Pro WCW-Series Operator’s Manual

WATER SUPPLY:

1.

Select a water supply hose which is a quality grade of garden hose measuring

at least 3/4" ID and no longer than 50 feet.

2

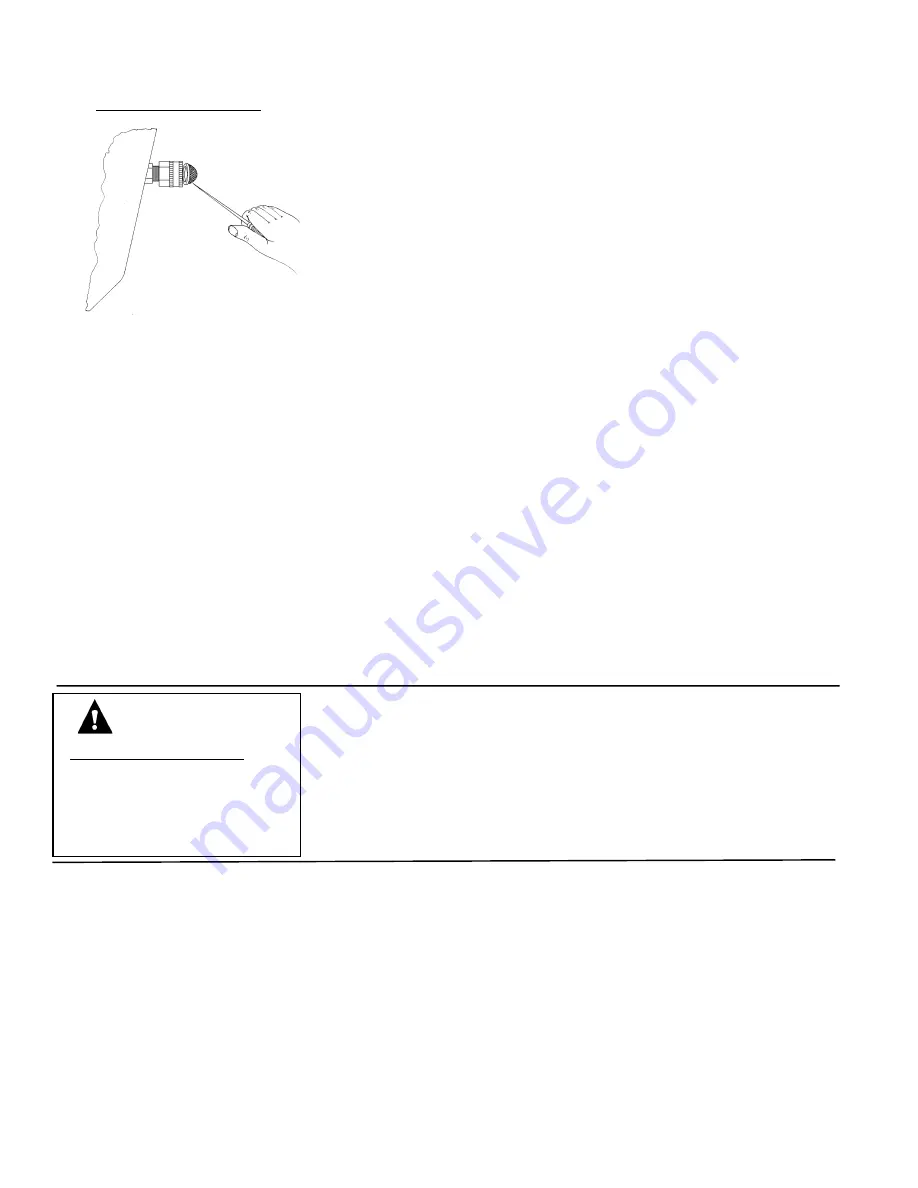

Check the water inlet strainer (9) to ensure it is clean and free of any

obstructions. Periodic cleaning of the water strainer will help prevent pump

problems. As a strainer becomes obstructed, it restricts proper flow of water

to the pump. This can result in cavitations which will cause premature failure

of pump packings. Using a screw driver, remove the screen from the water

inlet. Clean or replace with Mi-T-M #19-0001 if necessary.

3. Connect the hoses.

a.

Water supply hose to the water inlet (10) of the unit.

b.

Water supply hose to your pressurized water supply.

c.

The high pressure discharge hose (16) to the water outlet (11) of the

unit.

d.

The high pressure discharge hose to the gun assembly (17).

Be certain all connections are securely tightened.

NOTE:

If there is a high mineral content in your water, it is recommended that an

additional water strainer (Mi-T-M #851-0207), be added to the water inlet

to help reduce mineral content. Clean both strainers before starting your

pressure washer.

4.

Follow the incoming water requirements listed below:

a.

Water pressure must be a minimum of 20 pounds per square inch (PSI)

and a maximum of 125 PSI. (A typical outdoor faucet will generally

supply this PSI if turned completely "ON".)

b.

Incoming GPM must be approximately one gallon more than the outgoing

GPM stated on the pressure washer nameplate. (You can check GPM

by timing how long it takes to fill a 5 gallon container.)

c.

Incoming water temperature must not exceed 125°F. Excessive pump

damage may result if water temperature exceeds this acceptable level.

5.

Never allow the unit to operate without the incoming water line attached and

the water supply completely turned on.

WATER INLET STRAINER

IN-STRN.TIF/D1

OMGEN123/61290/BAR

INSTALLATION & PREPARATION

UNLOADER:

The unloader on your machine is equipped with an adjustment knob (13) to

adjust the pressure. Should less pressure be required, simply turn the adjustment

knob counterclockwise. To set back to maximum, turn adjustment knob

completely clockwise. DO NOT OVERTIGHTEN!

CAUTION

RISK OF UNIT DAMAGE!

DO NOT OVERTIGHTEN THE

UNLOADER. BREAKAGE

COULD RESULT IN IMMEDIATE

LOSS OF WATER PRESSURE

AND COSTLY REPAIRS.

HEAT DUMP VALVE:

To ensure the water temperature does not exceed acceptable levels, never

allow the pressure washer to operate in the bypass mode (with the unit running

and the trigger gun closed) for more than three minutes.

A "heat dump valve" (12) has been added to this unit to protect the pump. It

may begin to open and release water if the water temperature in the pump has

exceeded 140°F. This will allow fresh, cool water to enter the system.