16

Work Pro WCW-Series Operator’s Manual

STORAGE & MAINTENANCE

SPECIFIC MAINTENANCE:

ENGINE: The engine instructions that accompany your unit detail specific

procedures for maintenance of the engine. Following the engine

manufacturer’s recommendations will extend engine work life.

PUMP: The pump oil must be changed after the first 50 hours of operation.

After initial oil change, every 3 months or 250 hour intervals are

recommended. If oil appears dirty or milky, changes may be required at a

greater frequency. Use Mi-T-M

®

pump oil #AW-4085-0016 and fill only to

the center of the oil sight glass (8). DO NOT OVERFILL!

QUICK COUPLERS: There is an o-ring seal inside the female quick coupler.

This o-ring will deteriorate or, if the unit is allowed to pump without the high

pressure hose or nozzle attached, the o-ring may be blown

out occasionally. Simply insert a replacement o-ring to correct the

leak. (Additional o-rings can be purchased from your dealer.)

NOZZLES: Water flow through the spray nozzle will erode the orifice, making it

larger, resulting in a pressure loss. Nozzles should be replaced

whenever pressure is less than 85% of the maximum. The frequency of

replacement will depend upon such variables as mineral content in the water

and number of hours the nozzle is used.

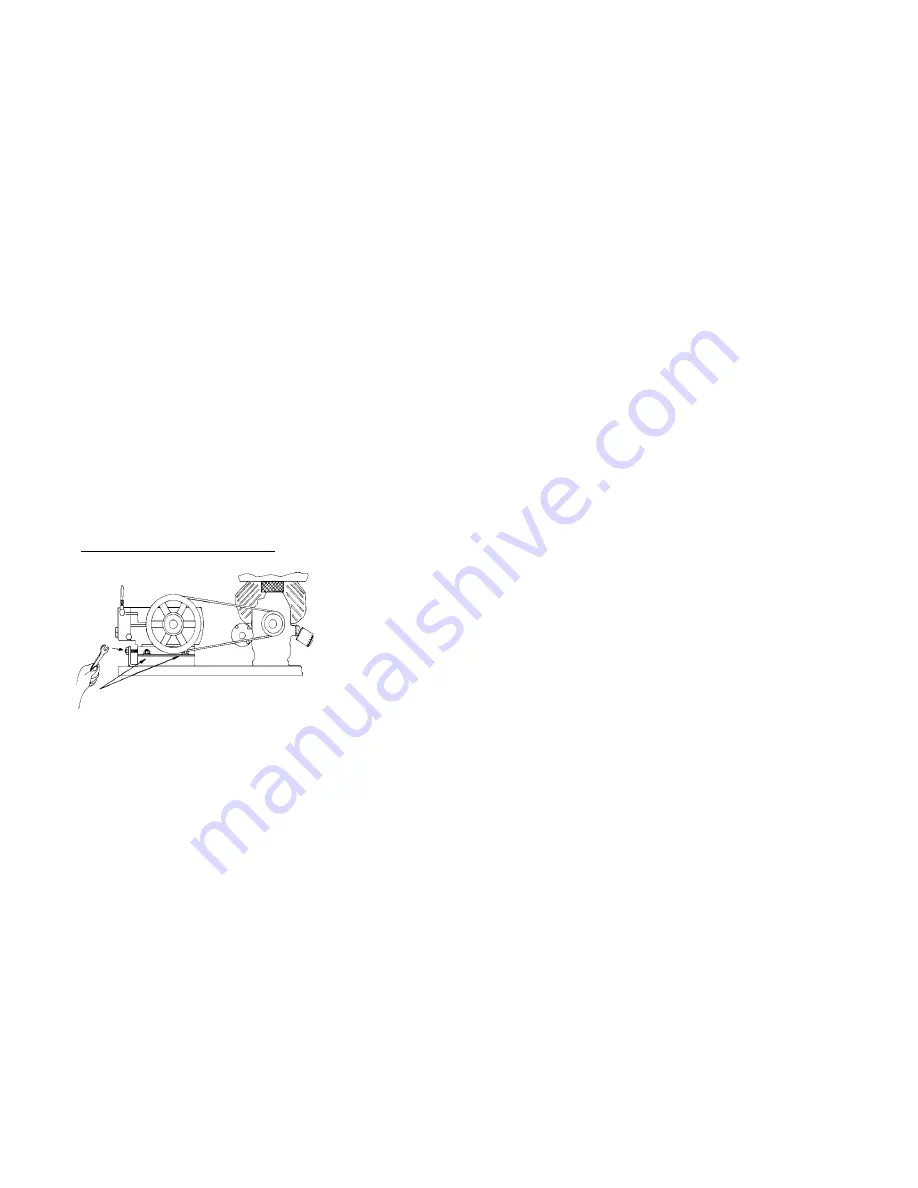

BELT TENSION ADJUSTMENT: To maintain peak performance of your pressure

washer, it may be necessary to adjust the belt tension on occasion. Follow

the procedure outlined below.

1.

Remove the belt guard and loosen the two nuts on each side of the

pump. (Reference A) There are a total of 4 nuts.

2.

Turn the cap screw (Reference B) clockwise until a 1/2 inch belt

deflection is noticed between the pulleys.

3.

Tighten the side nuts. (Reference A)

4.

Put a straight edge across both pulleys. If necessary, loosen one set of

pulley screws and adjust in or out to properly align. Tighten the pulley

screws and check the tension again.

5.

Replace the beltguard and tighten the fasteners securely.

LEAKS: Promptly eliminate any leaks found in the pumping system by removing

suspect parts, applying thread sealant to the threads and reinstalling.

NOTE:

If using teflon tape, be certain no tape gets inside any plumbing to

prevent the possibility of a plugged spray nozzle.

B

L

T-TITE.TIF/D1

BELT TENSION ADJUSTMENT

B

A