EN

12

24 DO NOT MODIFY THE COMPRESSOR

Do not modify the compressor. Always contact the authorized

service center for any repairs. Unauthorized modification may not

only impair the compressor performance but may also result in

accident or injury to repair personnel who do not have the required

knowledge and technical expertise to perform the repair operations

correctly.

25

TURN OFF THE PRESSURE SWITCH WHEN THE

COMPRESSOR IS NOT IN USE

When the compressor is not used, turn the knob of the pressure

switch OFF, disconnect it from the power source and open the

drain cock to discharge the compressed air from the air tank.

26 NEVER TOUCH HOT SURFACES

To reduce the risk of burns, do not touch tubes, heads, motors and

cylinder.

27 DO NOT DIRECT AIR STREAM AT BODY

Risk of injury, do not direct air stream at persons or animals.

28. DRAIN TANK

Drain tank daily or after 4 hours of use. Open drain fitting and tilt

compressor to empty accumulated water.

29. DO NOT STOP COMPRESSOR BY PULLING OUT THE PLUG

Use the “AUTO/OFF” knob of pressure switch.

30.

USE ONLY RECOMMENDED AIR HANDLING PARTS

ACCEPTABLE FOR PRESSURE NOT LESS THAN 125 PSI

(8.6 BAR)

Risk of bursting. Use only recommended air handling parts

acceptable for pressures not less than 125 psi (8.6 bar).

SAFETY GROUNDING INSTRUCTIONS

The compressor should be grounded while in use to protect the

operator from electric shock. The compressor is equipped with a three-

core cable and three-pin grounding type plug to fit the proper

grounding type socket. Never disassemble the compressor or carry out

other connections to the pressure switch.

WARNING

– the grounding must be carried out according to EN 60204

norms.

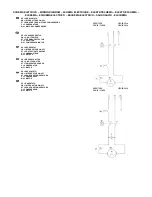

EXTENSION CABLE

Use only three-way extension cables that have

three-pin connecting plugs and three-pole sockets that accept the

compressor plug. Do not use extension cables that are damaged or

squashed. An under-rated cable will cause a drop in line voltage

resulting in loss of power and overheating. The table shows the correct

size to use depending on the length according to the following

parameters (size in [mm

2

] for a cable with maximum length of 20 mt.):

220/230V 110/120V

1,5 mm²

2,5 mm²

WARNING

Avoid electrical shock hazard. Never use this compressor with a

damaged or frayed electrical cord or extension cord. Inspect all

electrical cords regularly. Never use in or near water or in any

environment where electric shocks are possible.

INSTALLATION

Fit the suction cups underneath the base of the unit as indicated.

Position the compressor on a flat surface or one with a max. inclination

of 10° in a well-ventilated area. If the surface is sloping and smooth,

make sure that the compressor does not move while in operation. If

the compressor operates on a shelf or the edge of a stand, ensure that

it may not fall off by securing it appropriately.

START-UP

Ensure that the knob situated in the upper part of the compressor is

turned to “0”. Put the plug into the power socket and turn the knob to

“I”. Attach the rubber hose or the spiral type hose to the appropriate

fitting situated near the pressure switch. The compressor operates

completely automatically and is controlled by the pressure switch

which stops it when the pressure inside the tank reaches the maximum

pressure and starts it again when the pressure returns to the minimum

level. The difference in pressure is usually 2 bar (29 PSI). After having

connnected the compressor to the electrical power supply line, load to

the maximum pressure and check the correct efficiency of the

machine.

ADJUSTING THE WORKING PRESSURE

It is not always necessary to use the maximum working pressure. On

the contrary, a pneumatic tool usually requires less pressure. Adjust

the pressure to the required level by turning the knob clockwise to

increase it and anti-clockwise to decrease it. The pressure setting is

shown on the pressure gauge of the compressor.

MAINTENANCE

Before servicing the compressor, make sure that:

-the power cable is unplugged from the electricity supply.

-there is no pressure in the air receiver. The compressor generates

condensation that accumulates in the tank. The condensate must be

drained from the tank at least once a week by opening the condensate

drain valve underneath it. Be careful in case there is any compressed

air within the cylinder as the water could burst out with some force.

Recommended pressure 1-2 bar max.

TROUBLESHOOTING

Loss of air

This may be due to the poor seal of one of the fittings. Check all the

fittings by wetting them with soapy water. It is normal for the pressure

to drop when the compressor is not used, whatever the case (roughly

1 bar every 5 minutes).

The compressor fails to start

If the compressor has difficulty in starting, make sure that:

- all the wires are correctly connected.

- the mains voltage is efficient (plug connected correctly, magneto-

thermal switch, fuses unblown).

The compressor fails to stop

If the compressor fails to stop when the maximum pressure is reached,

the tank safety valve will cut in. It is necessary to contact your local

authorised service centre.

WARNING

-Do not drill, weld or intentionally deform the compressed air tank.

-Ambient temperature for correct operation of the compressor is

between 0°C and 25°C (max.45°C).

-When temporarily not in use, turn the ON/OFF switch to “0” (OFF).

-Be aware that some components of the compressor such as the head

and delivery hoses, may reach high temperatures, therefore do not

touch them to avoid the risk of burning.

- Transport the compressor by lifting it with the appropriate grips or

handles.

-If the compressor is used for painting: a) do not work in an enclosed

area or near naked flame b) ensure that the area in which you are

working has adequate ventilation c) protect nose and mouth with an

appropriate mask

-Do not direct airstream at people or animals to avoid serious injuries.

-Always unplug the compressor from the power socket when you have

finished using it.

TECHNICAL DATA

Maximum running pressure: 8.9 bar.

Maximum working pressure: 8 bar.

HP / W

RPM

dB(A)

1/800-1100 PEAK

2800

÷

3000

72

The sound pressure level measured in a free range at a distance of 4

mt. dB(A) at the maximum working pressure. The value of the sound

level may increase from 1 to 10 dB(A) depending on the environment

in which the compressor is installed.

WARNING

This compressor has been designed for DIY use with intermittent (not

continuous) operation. The use of the compressor for more than 20

min. during one hour is not recommended.

Summary of Contents for MB 3000

Page 2: ......