9

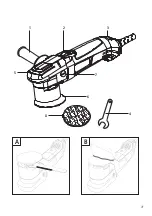

4. TOOL ASSEMBLY

Position the cap (5) on the gearbox such that the holes for mounting the

screws (7) are aligned with those on the gearbox.

5. ACCESSORIES ASSEMBLY

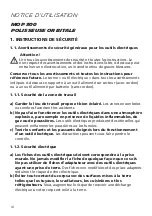

5.1. POLISHING DISC (A)

Fix the output shaft with the wrench(4), then slightly turn the polishing disc (6)

until it is fixed to the output shaft.

5.2. POLISHING FOAM (B)

5.2.1. Place the polishing pad (8) on one polishing disc and press it into

position with a slight turn.

5.2.2. To remove the polishing pad, take hold of it at one corner and pull it

upwards.

6. START AND STOPPING

6.1.

Starting:

push the lever of the switch (2) handle.

6.2.

Stopping:

push and release the lever of the switch (2).

The tool continues to rotate after it is turned off.

Do not run to “empty” the tool with the polishing pad mounted. In this

way, the polishing pad may be subject to lacerations.

7. SELECTING RPM (min

-1

)

The rpm can be adjusted by rotating the speed wheel (3). The choice of speed

depends on the characteristics of the abrasive disc and the material to be

worked with.

8. ALLOWED ACCESSORIES

Polishing foam Ø 130-150 mm for backing pad Ø 125 mm.

Summary of Contents for MOP 300

Page 3: ...3 8 5 4 7 6 2 1 3 A B...

Page 30: ...30 1 1 1 1 1 1 1 1 2 MOP 300...

Page 31: ...31 RCD RCD 1 1 3...

Page 32: ...32 1 1 4 1 1 6...

Page 33: ...33 1 2 1 3...

Page 34: ...34 1 4...

Page 35: ...35 2 3 4 5 7 5 5 1 A 4 6 5 2 B 5 2 1 8 5 2 2...

Page 37: ...37 11 EN 62841 1 3 675 m s2 1 5 m s2 12 13 2002 96 WEEE 2003 108 CE...

Page 38: ...38...