16

1.3 INTENDED USE

The models described in this manual are designed and

manufactured for intermittent use with a maximum

service factor of 30% (e.g. 3 minutes of work and 7 min-

utes of rest), under optimal environmental conditions

(max. temp 25°C). Respecting these guidelines and the

prescribed maintenance intervals will allow the product

to work properly over time.

1.4 GROUND CONNECTION

The single-phase compressor is equipped with an elec-

trical cable and a two-pole + earth plug.

It is recommended not to make any other connections

on the pressure switch.

Repairs must always be carried out by a qualified

technician.

1.5 USE OF AN EXTENSION CABLE

Only use extension cables with plug and ground

connection. Do not use damaged or crushed exten-

sion cords. An extension cable that is to thin can cause

voltage drops, loss of power and overheating of the unit.

The extension cable must have a cross-section propor-

tionate to its length.

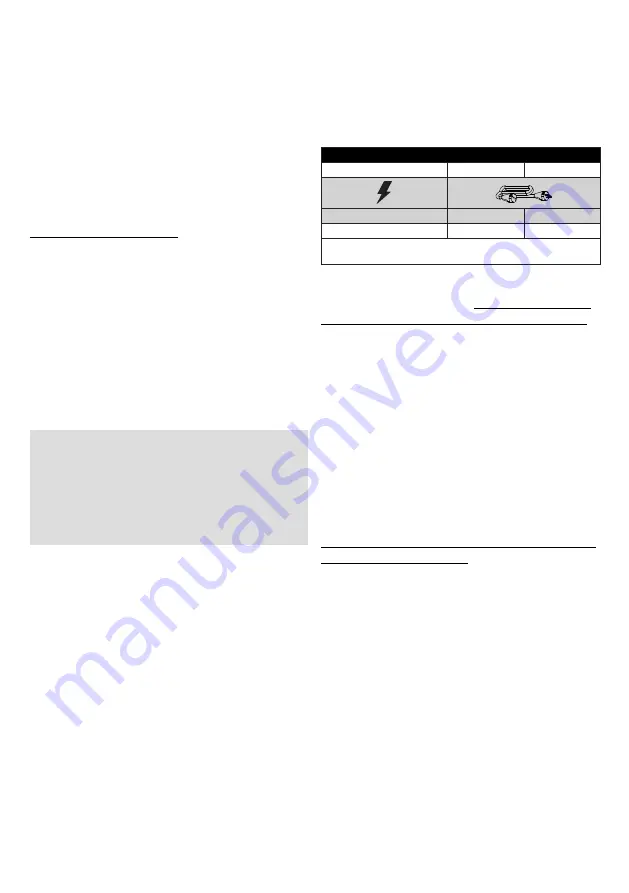

Check table A in order to choose the correct cable size

Tab. A

Volt

220-240

110-120

kW / HP

mm² (*)

mm² (*)

0,75 / 1

1,5

2,5

(*)

Cable cross-section for maximum length 20 m

WARNINGS

Avoid all risks of electric shock. Never use the compres-

sor with a damaged electrical cable or extension cord.

Check all electrical cables on a regular basis. Never use

the compressor in or near water or near a hazardous

environment where electric shocks are possible.

Note:

The information in this manual is provided to

assist the operator in operating and maintaining the

compressor.

Some illustrations may show details different from

those of your compressor.

WE RESERVE THE RIGHT TO MAKE ANY CHANGES

WITHOUT PRIOR NOTICE WHERE NECESSARY

2.1 INSTALLATION

Remove the compressor from its packing, make sure it is

in perfect condition and that it was not damaged during

transport, and

carry out the following operations:

• Fit the wheels and/or the rubber tab.

• Place the compressor on a flat surface, or with a slope

of no more than 10°, in a well-ventilated place, protect-

ed against atmospheric agents and in a non-explosive

environment.

• MAKE SURE THAT THE COMPRESSOR IS TRANSPORT-

ED PROPERLY, DO NOT OVERTURN IT OR LIFT IT WITH

HOOKS OR ROPES.

• If positioned on an inclined plane, make sure that the

compressor does not move and, if necessary, block the

wheels with appropriate means. If placed on a bracket

or shelf top, make sure that the support can bear the

weight and secure it properly so that it cannot fall.

• To ensure proper ventilation and effective cooling, the

compressor must be at least 50 cm away from any wall

or obstacle.

2.2 ELECTRICAL CONNECTION

The compressors are supplied with an electrical cable

and a two-pole + earth plug. The compressor must be

connected to grounded power socket protected by a

suitable differential switch (magneto-thermal).

2.3 START-UP

Check that the mains power matches the power indicat-

ed on the electrical data-plate. The permissible tolerance

range is +/-5%.

• Insert the plug into the power outlet and start the

compressor by turning the pressure switch knob

(5)

to

the “I / ON” position.

• The compressor is fully automatic, and is controlled by

the pressure switch which stops it when tank pressure

reaches the maximum value and restarts it when it

falls to the minimum value. The pressure difference

between maximum and minimum values is usually

about 2 bar (29 psi).

E.g. the compressor stops when it reaches 8 bar (116 psi

– maximum operating pressure) and restarts automat-

ically when the pressure in the tank drops to 6 bar (87

psi).

After connecting the compressor to the power line, load

it to maximum pressure and check that the machine

works properly.

Some models are equipped with a head discharge valve,

which facilitates the subsequent start-up. In this case, a

puff of air is normal when the motor stops.

EN

1. FOREWORD

2. INSTALLATION AND USE