5.5

Protective and Operational Grounding

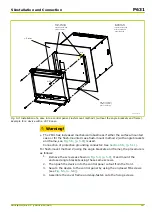

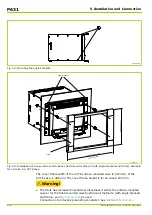

The device must be reliably grounded to meet protective equipment grounding

requirements. The surface-mounted case is grounded using the bolt and nut,

appropriately marked, as the ground connection. The flush-mounted case must

be grounded in the area of the rear sidepieces at the location provided.

The bracket is marked with the protective ground symbol:

The cross-section of the ground conductor must conform to applicable national

standards. A minimum cross section of 2.5 mm² (

≤

AWG12) is required.

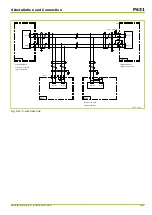

In addition, a protective ground connection at the terminal contact on the power

supply module (identified by the letters “PE” on the terminal connection

diagram) is also required for proper operation of the device. The cross-section of

this ground conductor must also conform to applicable national standards. A

minimum cross section of 1.5 mm² (US:

AWG14 or thicker) is required.

If a detachable HMI is installed, a further protective conductor (ground/earth) of

at least 1.5 mm² (US:

AWG14 or thicker) must be connected to the DHMI

protective conductor terminal to link the DHMI and the main relay case; these

must be located within the same substation.

All grounding connections must be low-inductance, i.e. it must be kept as short

as possible.

19Y5220B

1

2

3

4

1

2

3

4

PE terminal

Description

Nut M4

Bolt M4

Clamp bracket

Tooth lock wash.A4.3

surface-mount. case

PE terminal

Description

Nut M4

Bolt M4

Clamp bracket

Tooth lock wash.A4.3

flush-mount. case

Pos.

1

2

3

4

Pos.

1

2

3

4

Fig. 5-8: Installing the protective grounding conductor terminal.

The protective conductor (earth) must always be connected to the protective

grounding conductor terminal in order to guarantee the safety given by this set-

up.

5 Installation and Connection

P631

P631/EN M/R-11-C // P631-310-650

5-11

Summary of Contents for P631

Page 2: ......

Page 4: ......

Page 7: ...Changes after going to press...

Page 8: ......

Page 16: ...P631 Table of Contents 8 P631 EN M R 11 C P631 310 650...

Page 56: ...P631 2 Technical Data 2 28 P631 EN M R 11 C P631 310 650...

Page 236: ...P631 3 Operation 3 180 P631 EN M R 11 C P631 310 650...

Page 246: ...P631 4 Design 4 10 P631 EN M R 11 C P631 310 650...

Page 266: ...P631 5 Installation and Connection 5 20 P631 EN M R 11 C P631 310 650...

Page 276: ...6 8 Configurable Function Keys P631 6 Local Control HMI 6 10 P631 EN M R 11 C P631 310 650...

Page 548: ...P631 10 Commissioning 10 10 P631 EN M R 11 C P631 310 650...

Page 568: ...P631 12 Maintenance 12 8 P631 EN M R 11 C P631 310 650...

Page 570: ...P631 13 Storage 13 2 P631 EN M R 11 C P631 310 650...

Page 572: ...P631 14 Accessories and Spare Parts 14 2 P631 EN M R 11 C P631 310 650...

Page 576: ...P631 15 Order Information 15 4 P631 EN M R 11 C P631 310 650...

Page 582: ...P631 A2 Internal Signals A2 4 P631 EN M R 11 C P631 310 650...

Page 608: ...P631 A4 Telecontrol Interfaces A4 18 P631 EN M R 11 C P631 310 650...

Page 637: ......