4

MAE2200

®

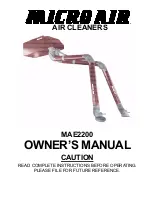

OPERATION:

CAUTION: ALWAYS MAKE SURE THAT ARM ASSEMBLY

IS FREE FROM OBSTRUCTIONS WHEN LIFTING OR

LOWERING MOTORIZED ARM.

1.

For motorized arm systems, the upper arm section can

be raised and lowered by depressing the toggle switch,

located on top of the remote switch control box, located

near the hood. The linear actuator has limit switches that

override the toggle switch when the arm exceeds the

retracted or extended length of the actuator.

2.

Grasp the nozzle handle and lift the lower arm section up

and down. If the middle joint seems too tight, loosen the

two wing nuts that hold the joint together. If the arm has

trouble maintaining a position, hand tighten the wing nuts.

3.

The nozzle-joint section can be manipulated up, down and

rotated. The joints are located inside the flexible hose

nearest the nozzle. If the joints are too loose or tight,

simply remove the hose clamp at the nozzle, gaining

access to the joints, and adjust as needed. (See

FIG. 6

.)

4.

To operate blower, depress the fan switch located on the

remote switch control box to ON. The blower motor will

activate via a motor relay located inside the electrical

control box.

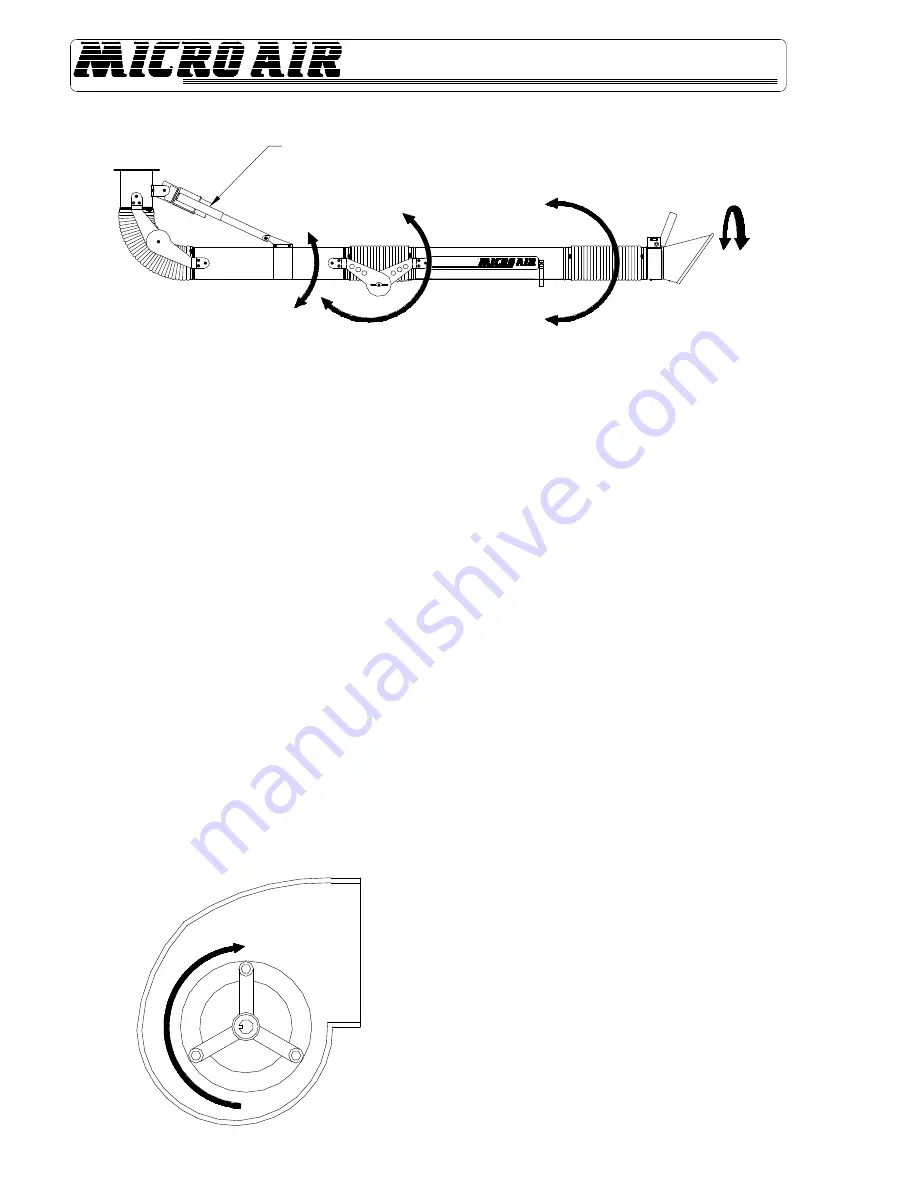

5.

Be sure to check for proper blower rotation. If blower is

rotating backwards, interchange L1 and L2. (See

FIG. 7

.)

6.

Activate the lamp located inside the nozzle by depressing

the lamp switch located on the remote switch control box.

ACTUATOR (OR RIGID PIPE)

90° UP

45° UP

20° UP

90° DOWN

45° DOWN

20° DOWN

7.

The damper lever near the nozzle can be rotated 90° to

adjust inlet air velocity.

PRESSURE SWITCH ADJUSTMENTS

1.

Make sure filters and pre-filters are installed in unit.

2.

The pressure switch is preset at the factory to indicate

(light on) dirty filters, but may need readjustment due to a

desire for earlier or later filter changes, a different

combination of filters, or because the set point shifted

during shipping. To readjust the switch, remove the hole

plug in the side of the unit for access to the adjustment

screw. Turn the unit on and place a piece of cardboard

over the hood covering about 80-85% of the intake. With

a standard screwdriver, turn the adjustment screw

clockwise until the light goes off, or

counterclockwise until the light comes on.

3.

For more time between filter changes (less airflow), cover

slightly more of the hood, and for less time between filter

changes (more airflow), cover less of the hood.

CHANGING FILTERS

CAUTION: ALWAYS MAKE SURE THAT THE UNIT IS TURNED

OFF BEFORE CHANGING FILTERS OR SERVICING THE UNIT.

1. The MAE 2200 is equipped with a filter change light, which

indicates when a filter needs to be replaced. If the differential

pressure has been set properly, the light signals the need for

examination of the filters.

2. When the light comes on, turn the unit off and remove the

pre-filter only. Replace with a new pre-filter, making sure that

the air flow directional arrow is pointed toward the outlet end.

Turn the unit back on. If the filter change light is off, then the

unit is operating properly.

3. If the filter change light fails to go out after replacing the pre-

filter, then the media bag filter may also need to be replaced.

4. Visually inspect the bag filter. If the pockets are loaded with

dirt, then remove the filter from the channel and insert a new

filter.

5. Start the unit. The filter change light should be off and the unit

operating properly.

FIG. 7