2

MODEL OM550DD SPECIFICATIONS

Input Volts:

120 VAC, Single Phase

230 VAC, Single Phase

208-230/460 VAC, 3 Phase

Max. Current:

1/2 HP 120 VAC

7.6 AMPS

1/2 HP 230 VAC

3.8 AMPS

1/2 HP 208/230/460 VAC 2.6/2.0/1.0 AMPS

3/4 HP 120 VAC

10 AMPS

3/4 HP 230 VAC

5 AMPS

3/4 HP 208/230/460 VAC 2.8-2.4/1.2 AMPS

Motor:

1/2 HP TEFC Single Phase

1/2 HP TEFC 3-Phase

3/4 HP TEFC Single Phase

3/4 HP TEFC 3-Phase

Air Flow*:

6” inlet 450CFM (1/2 HP Motor)

6” inlet 600CFM (3/4 HP Motor)

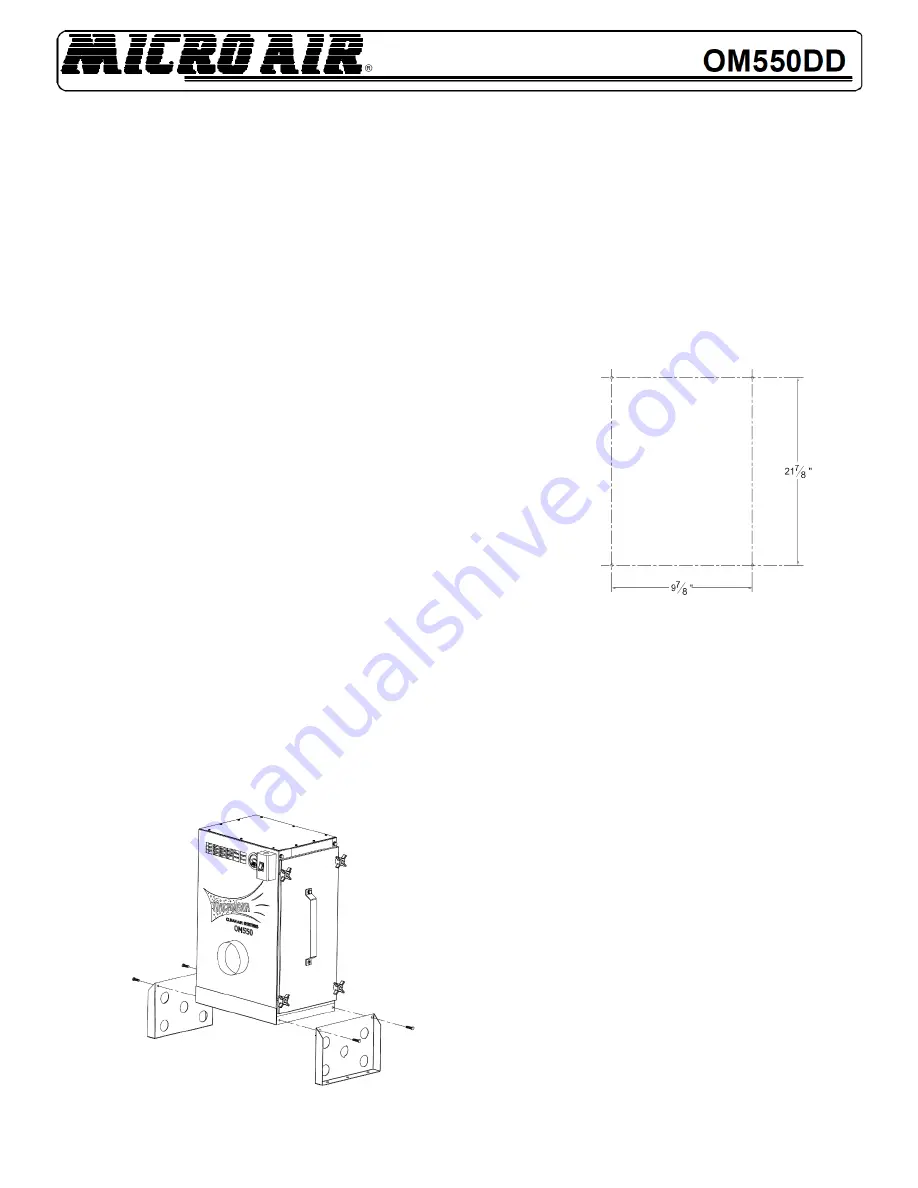

Dimensions:

31 3/8” H x 20” W x 14” D (less Brackets)

40” H x 20” W x 14” D (with Brackets)

Shipping Weight: 136 lbs.

Actual Weight:

116 lbs.

*All airflows are tunnel-tested readings.

PACKAGE CONTENTS

1ea.

OM550DD Unit

2ea.

Machine Mount/Hangar Brackets

1ea.

Owner’s Manual

PRE-OPERATING INSTRUCTIONS

1. Remove OM550DD unit and mounting brackets (not

assembled) from crate packaging.

2. Inspect unit for shipping damage and report any damage

to freight carrier.

INSTALLATION INSTRUCTIONS

A. MACHINE MOUNT / FLOOR MOUNT

1.

Remove two 5/16” bolts from each side of cabinet

near the bottom of the unit

FIG.1

2. Use the bolts removed in Step 1 to secure Machine

Mounting brackets to unit as shown in

FIG.1

.

3. Locate an installation site that will provide for the

following:

A solid structure capable of supporting the weight

of the unit.

Three feet of unobstructed exhaust space from

the outlet of the unit.

Easy access to service panels and unit inlet. As

near as possible to the source of the oil mist unit

to be captured.

4. Mark location of the mounting holes on the surface to

which unit is to be mounted, (see

FIG.2

for hole

pattern). Drill or punch holes that are sized for

mounting hardware to be used.

FIG.2

5. Lift OM550DD unit onto machine, aligning machine

mount brackets over mounting holes previously

drilled. Secure to machine using standard bolts, nuts

and lock washers.

CAUTION: The size and weight of the OM550DD requires

two persons or mechanical means to lift and hold during

mounting

.

6. Connect unit to oil mist source using a duct having the

same diameter as the inlet of the unit. The duct may

be flexible hose or formed sheet metal. Maximum flow

will be obtained with minimum bends in duct. To

contain oil that will collect on the inside of the duct,

the duct must be sealed. Use hose clamps or sheet

metal screws to attach duct to unit.

B. CEILING MOUNTING

NOTE:

The Machine Mount/Hangar Brackets used in Section

A may be used for suspension mounting purposes.

1.

Remove the two 5/16” bolts from each side of the

cabinet at the outlet end.

2. Use the bolts removed in Step 1 to secure the ceiling

mount brackets to the unit as shown in

FIG.3

.

3.

Locate an installation site that will meet the

requirements listed in Step 3 of the machine mounting

instruction.

Summary of Contents for OM550DD

Page 5: ...5 FIG 5 ...