MICRO AIR

®

XA34

CLEAN AIR SYSTEMS

!

!

2

WARNINGS:

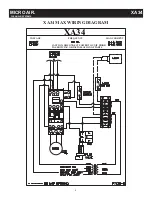

All electrical work must be done by a

qualified electrician according to local, state

and national codes.

CAUTION: Installation can cause

exposure to live components. Disconnect

electrical power before proceeding with

installation. Proper Lock Out / Tag Out

procedures should be used.

Improper installation or operation of this

equipment can cause damage to equipment

and / or injury to personnel. The

installation/operation manual must be read

and followed in its entirety.

SPECIFICATIONS XA34:

Input Voltage:

230/460 VAC 3-Phase

Motor:

3 HP TEFC

Max Current:

8.4/4.2 Amps

Filter Area:

200-348 square feet (media

dependent)

Load Capacity:

1,000 pounds

Air Flow:

3,720 CFM

Capture Velocity:

250 FPM average @ 1” above

work surface.

Noise level:

79 dBA at operator

74 dBA at operator with silencer

Overall Dimensions: Base table: 36H x 58W x 37D

With shields: 73H x 58W x 37D

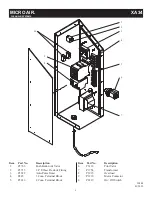

COMPRESSED AIR REQUIREMENTS:

3/4” Air line with clean, dry compressed air regulated

to 80-90 psi max is required for proper operation of the

Roto-Pulse filter cleaning system. It is recommended that a

pressure regulator and coalescing filter be installed between

the compressed air source and the inlet to the down draft

table.

EQUIPMENT/TOOLS REQUIRED:

Standard wrenches

Forklift

Pipe wrench

Cordless drill

INSTALLATION:

1. Inspect the Unit for any visible damage that may have

occurred during shipment. Note any damage on the

packing slip.

2. Uncrate the unit. Use caution not to damage the paint

while dismantling the crate.

3. Remove any options ordered from the skid.

4. Using a forklift, lift the unit off of the skid. Carefully

place the downdraft table into its location.

5. Connect compressed air supply to the 3/4” NPT nipple

on the unit.

6. Connect the wire whip to the appropriate plug based

on unit and voltage ordered. Plug into properly sized

electrical outlet.

7. Mount any optional accessories per instructions if

ordered.

OPERATION:

•

To start the unit, toggle the switch located on the front

of the unit to the ON position. To stop the unit, toggle

the switch to the OFF position.

•

If equipped: To turn the light on toggle the switch

located on the front of the unit to the ON position. To

turn the light off, toggle the switch to the OFF position.

•

To clean filters depress and hold down the pulse

push-button for 2 seconds at least once per hour, and

once after shutdown.

•

Units equipped with auto-pulse do not require manual

activation of the pulse system while the unit is running.

The filters will clean automatically for 2 seconds, every

45 seconds that the unit is running. It is recommended

that at least one manual pulse is completed after the

unit is turned off.

FIG 1.

Pulse Push Button

Wire Whip

Copressed Air

Connection

Light Switch

Motor Switch

Summary of Contents for XA34 Max

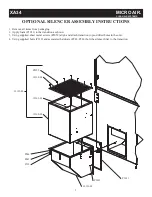

Page 7: ......