Page 25

Assembly

optoNCDT 1900 / EtherCAT

5.1.2.6

Surface Roughness

Laser-optical sensors detect the surface using an extremely small laser spot. They also track slight surface unevenness. In contrast, a

tactile, mechanical measurement, e.g. using a caliper, detects a much larger area of the measuring object. In case of traversing mea-

surements, surface roughnesses of 5 µm and more lead to an apparent distance change.

A suitable averaging number may improve the comparability of optical and mechanical measurements.

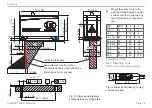

h > 5 µm

Max.

Min.

Ceramic reference surface

Structured surface

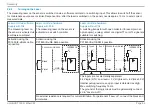

Recommendation for parameter choice:

- The averaging number should be selected in such a way that a surface area the size of which is comparable to those with mechani-

cal measurements is averaged.

Summary of Contents for ILD1900-10

Page 8: ...optoNCDT 1900 EtherCAT ...

Page 110: ...Page 110 Appendix EtherCAT Documentation optoNCDT 1900 EtherCAT ...

Page 111: ......